Renn RMC 12-SC Electric Roller Mill | 6 GPI Corn | Single Phase

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

*To Complete Unit, A Electric Motor Must Be Added – See Below

*Additional Groove Patterns Available For Wheat & Milo Upon Order

*Back Freight – $1,250

Unit Includes

- Bottom Hopper With Cross Auger Bearing Support

- 1:1 Drive

- Electric Drive Kit With Motor Pulley

- 12.75″ x 12″ Cast Rolls

Renn Roller Mills

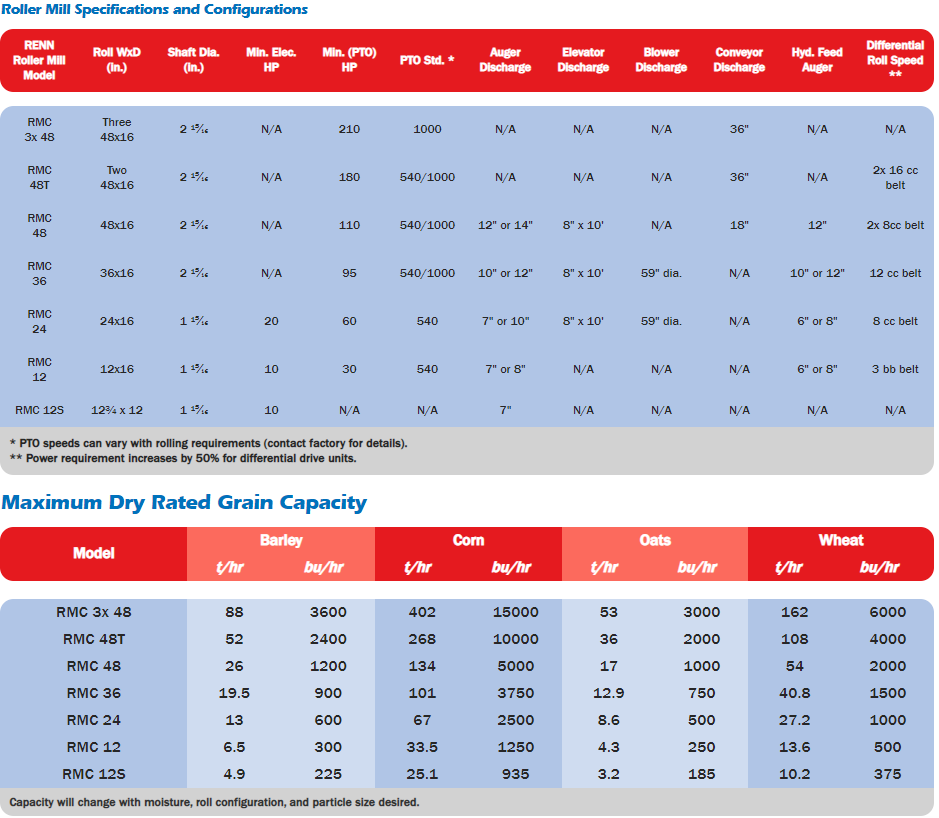

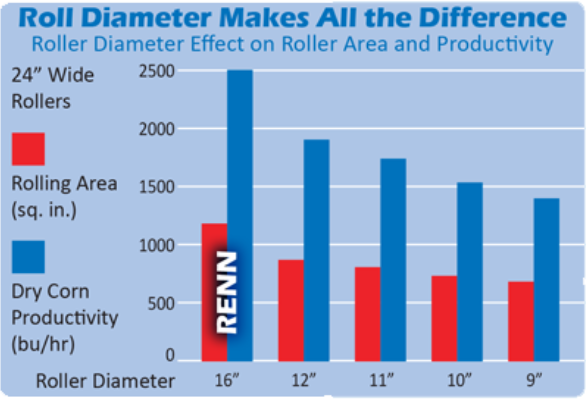

For the last 60 years the heart of the RENN Roller Mill has been its precision-machined 16” diameter rolls. The large diameter provides more rolling area per revolution compared to other brands of roller mills with their smaller diameter rolls. RENN Roller Mills save you time and money year-after-year by rolling more grain per hour with less horsepower.

RENN’s unique chill-cast rolls are our latest advancement in rolling technology. These centrifugally-poured, chill-cast rolls give you the wearability of cast rolls with the enhanced serviceability of removable shafts and end plates. Our innovative design team has developed an alternative to the conventional solid core cast roll; incorporating a 16” diameter casting that has a 3” thick sidewall. This new roll has the performance and wearability of chill cast rolls with the advantage of a lower power requirement and better economics as you are no longer paying for the unusable part of a roll; the center core.

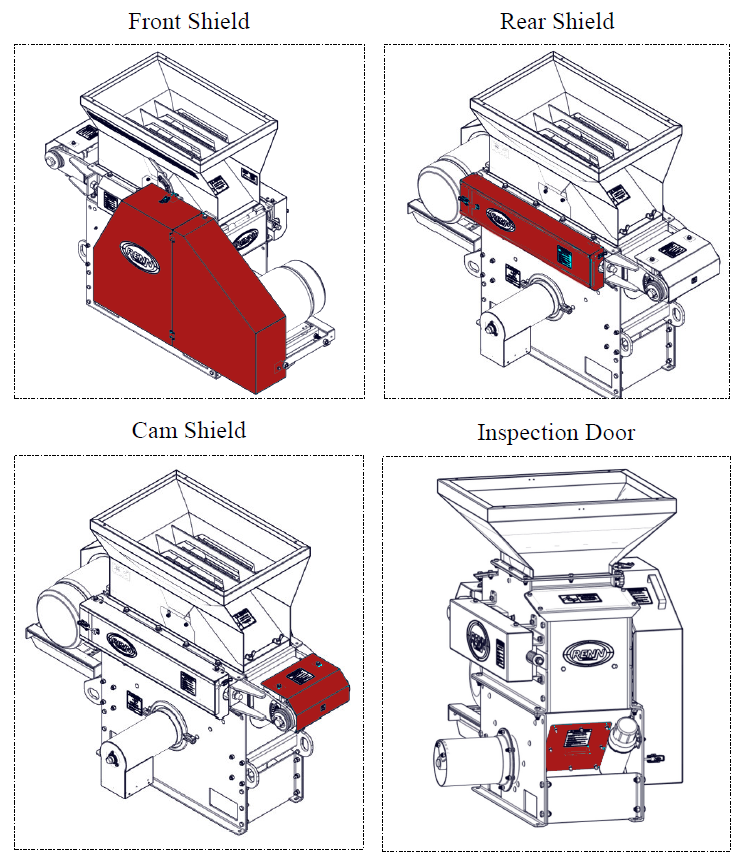

The RENN Roller Mill design is proven for operator efficiency and serviceability. The RENN worm drive roll adjustment allows for easy roll gap adjusting while the RENN leaf spring holds the rolls in place for maximum rolling capacity. After thousands of tonnes of work the rolls can be pulled for service in minutes due to RENN’s tip up top hopper and split frame design, regrooved and quickly reinstalled for thousands of tonnes of more trouble free rolling. The performance of the RENN Roller Mill is second to none. The 16” diameter RENN Roller Mill will always outperform any small diameter roller mill.

RENN 40% Differential Drive

- Offers optimum particle size

- Provides self-cleaning to prevent plugging

- Idler and driver rolls are positively driven at a 40% speed differential for optimal particle reduction

- Largest differential in the industry

Powering the Mill

- RENN Roller Mills are available as PTO powered trailer or Electric Stationary models.

- PTO models have minimum power requirement of 40 to 300 horsepower while Electric Stationary units operate with a minimum power requirement of 10 to 50 horsepower.

FYI-In The Past, We Have Had Trouble With The DY6K970 Motor Fitting On This Unit.