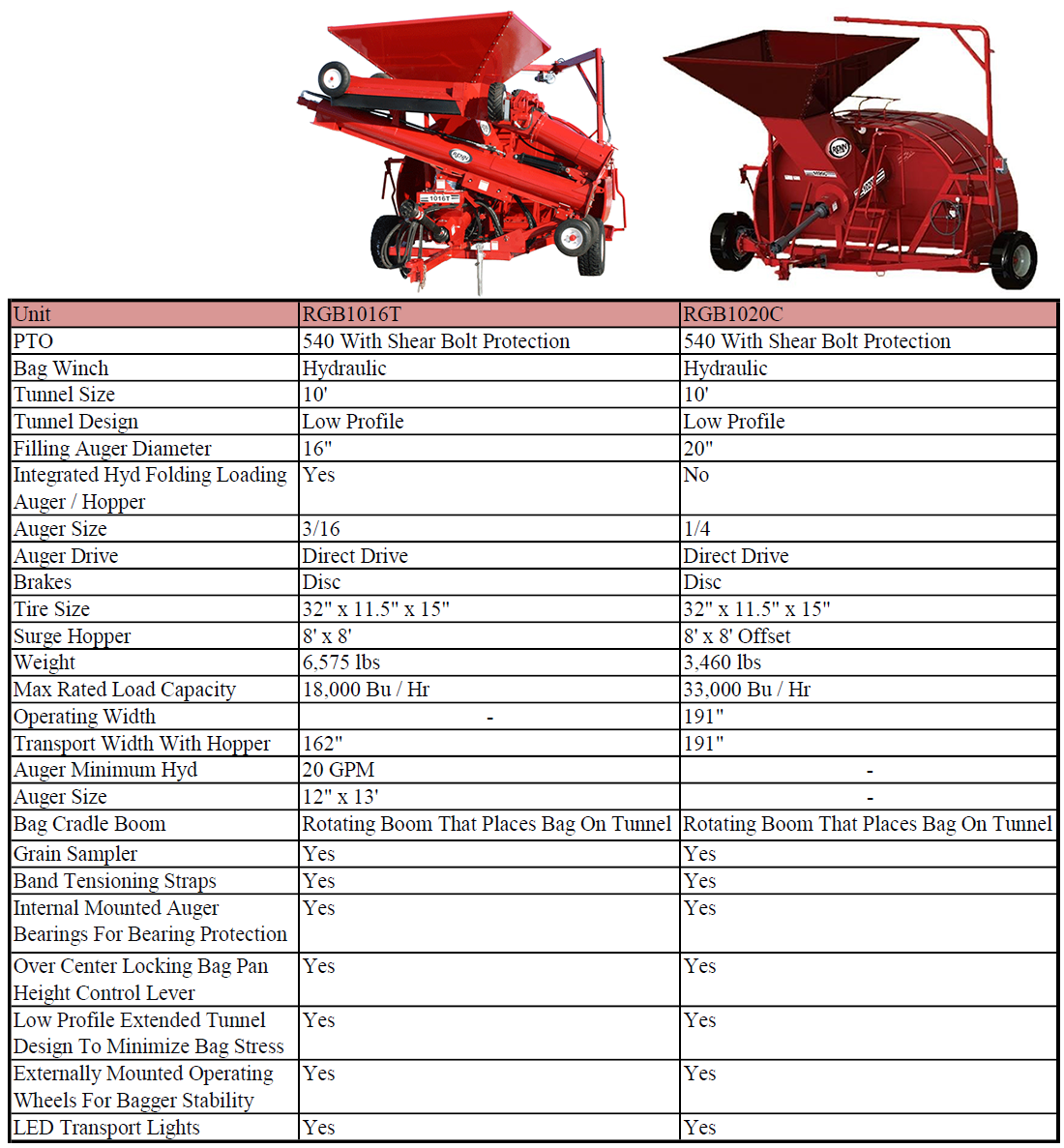

Renn RGB1016T 10′ Grain Bagger | 540 PTO | 8’x8′ Surge Hopper | LED Lights | Hyd Folding Loading Auger/Hopper

*Back Freight: $2,000

*PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

RGB1016T Grain Baggers

• On-board, telescopic swing auger

• Compact folded-auger design for easy transport

• Go from transport to working mode in seconds

• Flexibility of truck and/or hopper unloading

• Convenient hand-held remote control

• Wide tire placement prevents ruts under bags

The RGB 1016T adds a convenient on-board telescopic swing auger to the proven RENN grain bagging system in a compact, easy to transport machine. A hydraulic folding in-feed auger transforms the RGB 1016T from transport mode to operating mode in seconds. The unique rack and pinion system quickly extends or retracts the telescoping auger placing it under the truck or trailer. The hydraulic ground drive moves the auger horizontally under the trailer to reach different dump hoppers, minimizing truck movement. The telescopic swing auger, hydraulic ground drive, and bag crane are all conveniently operated from a single remote control. The RGB 1016T fills 10’ bags at up to 18,000 bushels per hour and requires a tractor with just 80 horsepower and 20 gallons-per-minute hydraulic capacity. Once the grain bags have been filled the innovative folding design makes the RGB 1016T easy to maneuver on roads, around bags, and in farm yards or storage sheds.

Faster, Smoother Grain Bag Loading…Minimize Risk Of Bag Tears & Spills

The unique, low-profile design of the RENN Bagger tunnel resembles the natural shape of a filled grain bag for smoother filling and less stress on the bag – minimizing the risk of tears and spills. RENN Grain Baggers allow farmers to reduce downtime with unique features such as our bag cradle, control harness, and crane system that work together to lift and place heavy grain bags on the tunnel, gently and easily.

The full-length auger design of the RENN Grain Bagger ensures the fill point of the hydraulic feed conveyor is low to the ground. This gives the operator maximum bagger travel from a single unloading point, eliminating the need to continually move the grain truck or cart during the bagging process. When bagging is completed, the conveyor hydraulically lifts off the bagger for transport.

| Weight | 3275 lbs |

|---|