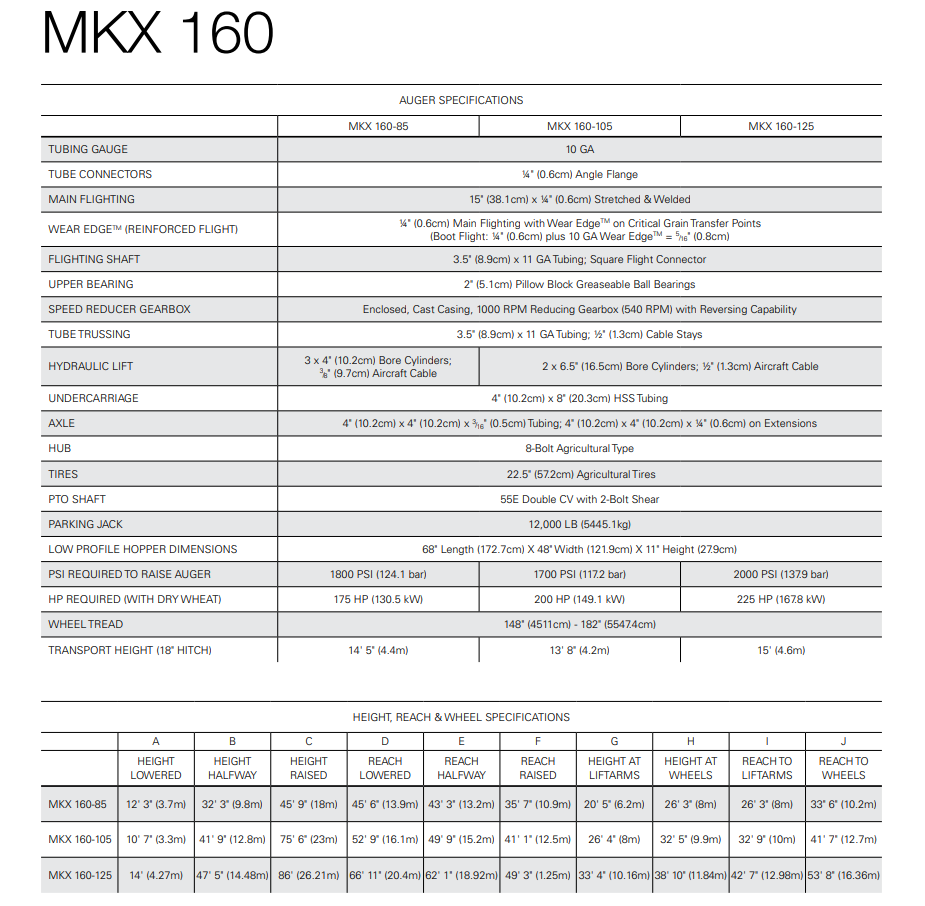

Westfield 16″ X 105′ MKX2 Auger | XTEND W/ Hyd Lift & Elec Swing | 1000 Red. Rev. | Up To 23,000 BPH

*Unit Weight – 15,780 lbs.

*PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

Shipped Complete With

- 1000 RPM Reducer Reverser

- Shielded 20 Spline CV-PTO Driveline With Overload Shear Bolts (21 spline CV-PTO tractor 1/2 shaft Available. This must be specified on the order form. If not specified, we will ship the auger with a 20 spline tractor output shaft)

- Dual Hydraulic Lift Cylinders With Shut-Off Valve

- X-Tend Hopper

- Hydraulic Hopper Lift System

- Remote Electric Power Swing

- Auger Steer

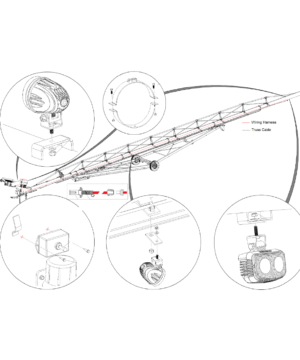

- Transport & Work Light Bundle

- 22.5″ Tires Mounted On Rims

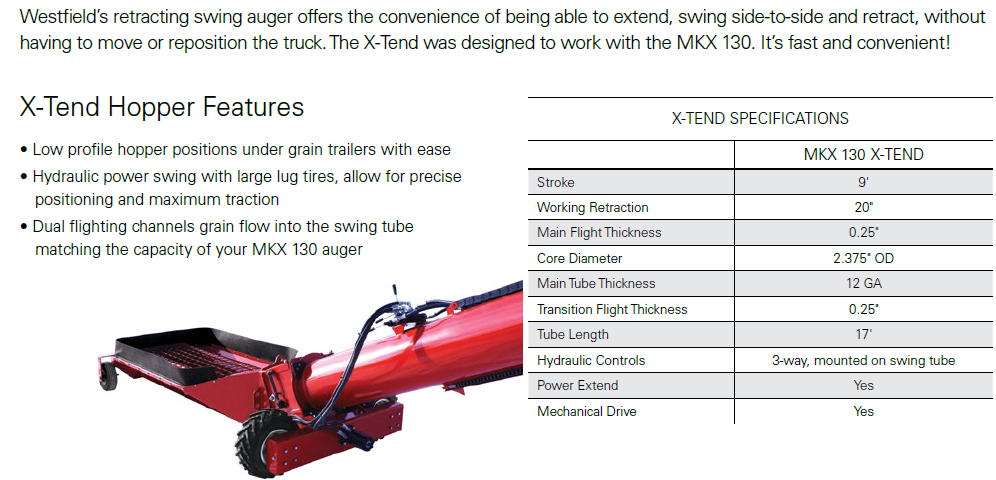

X-Tend Hopper –

New MKX2 Features

- Open Discharge Spout

- Reduced horsepower requirements

- 13” auger = 20% less horsepower required

- Allows for more efficient flow out of the tube

- New tapered bearing for increased life span

- Equipped with plastic hood for sleeker appearance

- Included on 10”, 13”, and 16” augers

- Reduced horsepower requirements

- Steerable Axles

- Improves auger maneuverability around tight corners in transport

- Improves auger maneuverability when lining auger up to the bin hole

- Optional on 13-84/94/114

- Standard on 16” augers

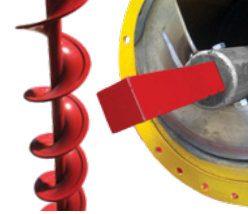

- Redesigned Boot

- Separate boot flight with removable shafts (10”, 13”, and 16”)

- AR boot flight standard (13” and 16”)

- Hanger bearing to support boot flight (13” and 16”)

- Tapered lower bearing for increased life span (13”)

- Clean-out doors on both sides of the boot (13”)

- Updated PTO and hose holders (13”)

- Transition Neck Flight Support

- Replaced bushing with self-aligning bearing

- Longer lasting life-span

- Splined connection to hopper u-joint provides better alignment and adjustability

- Included on 13” and 16” augers

- Replaced bushing with self-aligning bearing

- 30’ Tubes and Flights

- Less tube flange and flight connections lead to less auger noise

- Less tube and flight hardware reduces time needed to assemble

- Common flight and tube lengths leading to less variation to stock

- Included on 10”, 13”, and 16” augers

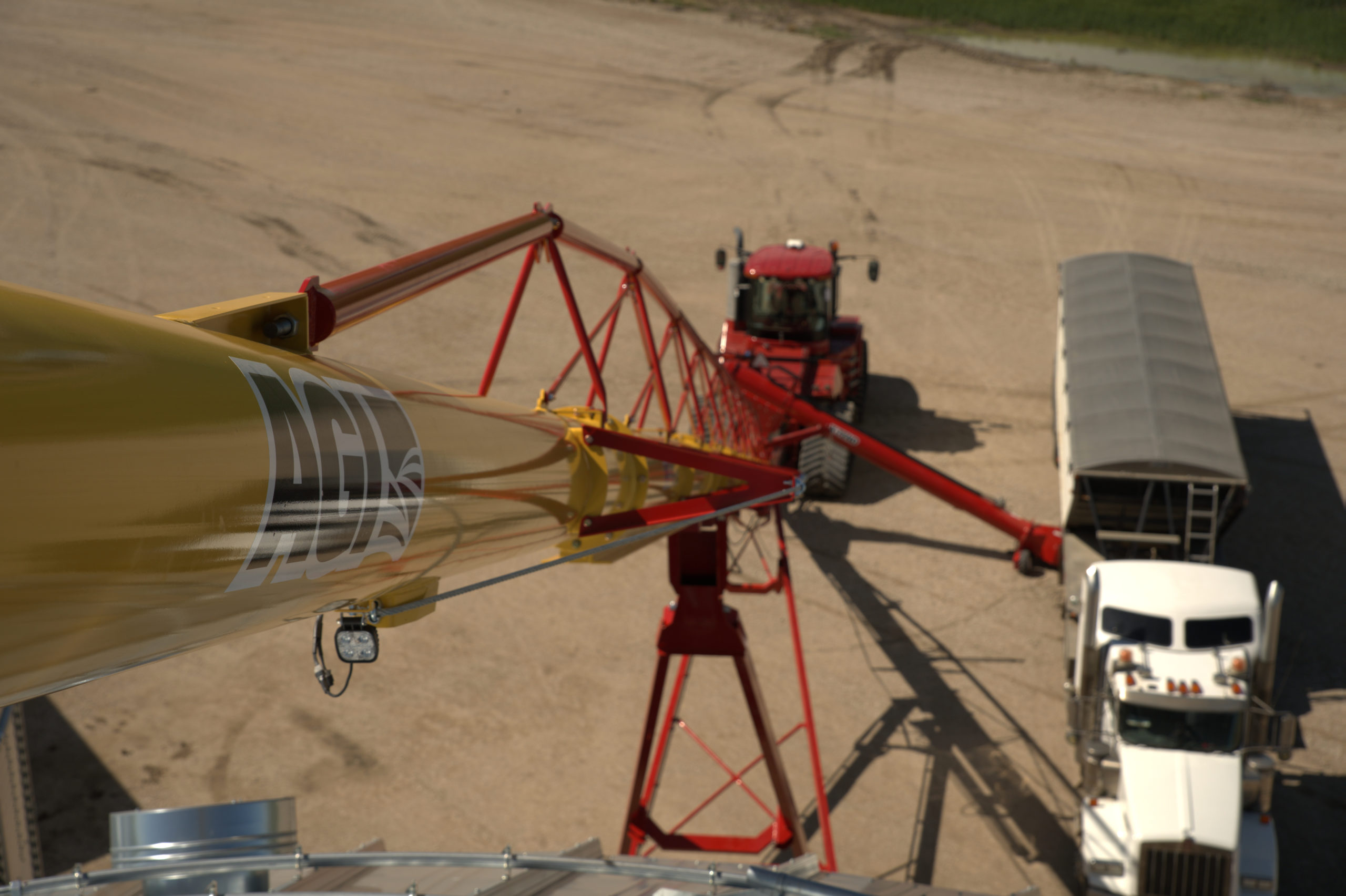

- 16” Truss Updates

- Simplified truss connections

- Fewer components/hardware reducing time to assemble

- Similar to 13” design

- Simplified truss towers and reduced number of side cable trusses

- Fewer components/hardware reducing time to assemble

- Adjustable cross brace members

- Simplified truss connections

- Right Angle Drive

- Improved gearbox stability

- Accepts adjustable tow bar

- New right angle drive with speed reducer

- Allows auger to be positioned at 90 degree angle from the truck

- Reduces speed of 1000 RPM tractor to 540 RPM required to run an auger

- Auger Lean Prevention

- Vertical stabilizer brace between lower frame arms to lock and prevent tube from rotating in transport position

- Stays engaged through lift assist range of motion as auger is raised and then disengages

- Nylatron GSM material provides a low friction surface to prevent binding

- Included on MKX² 13” a-frame augers equipped with X-Tend or X-Over swings

- Cylinder Updates

- Commonize cylinders to use with various auger sizes

- Fewer cylinders required to stock

- Change from internal check valve to external check valve

- Easier to access/service/replace in the field

- Commonize cylinders to use with various auger sizes

- X-Over

- New mechanical drive

- No hydraulic motor

- Factory set auger flight and belt speeds

- Redesigned belt interface and added seals to limit leakage

- Redesigned, reinforced drive-over deck and ramps to better handle multiple drive-overs

- New mechanical drive

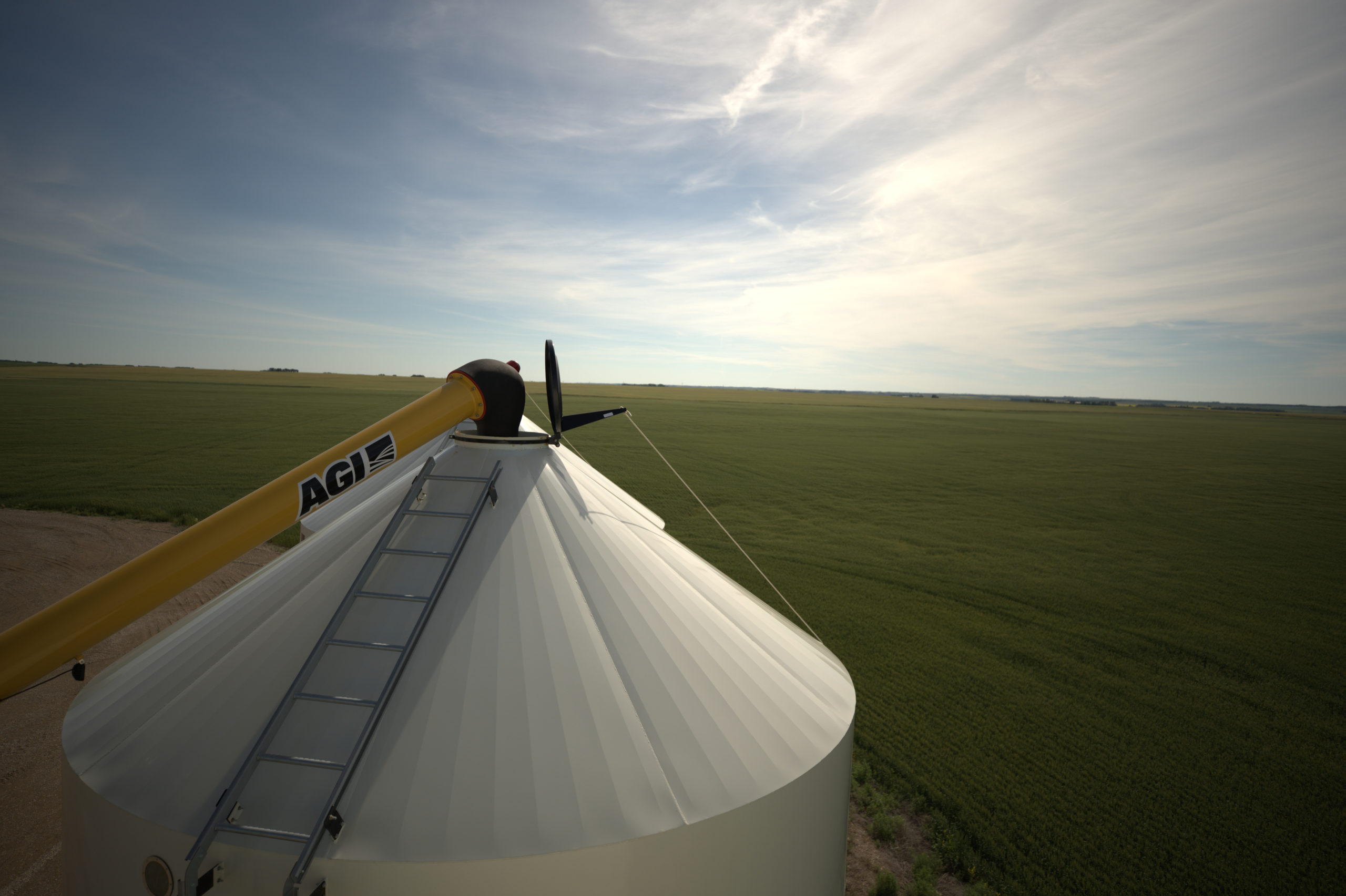

MKX2 160 Series

The heavy-duty, high capacity MKX2 16 Auger comes with an electric remote swing hopper for added convenience, while it’s A-frame undercarriage is built to hold the auger in position.

Westfield designed every detail of the MKX2 16 for today’s demanding large farm and commercial operators. From the engineered top truss, for added strength and stability, to a long list of standard features, the MKX2 16 is built to last.

Built Strong & Lasts Long

Westfied developed Wear Edge Technology™ to extend the life of the flighting. This provides an extra layer of steel welded to the edge on critical wear points. As a result, flighting lasts longer and needs to be replaced less often – saving time and money. To protect the finish and prevent rusting, Westfield uses a durable powder coat paint. Stronger abrasion resistant flighting available under options!

Service and Maintenance

The MKX2 Series features six easily accessible service points to allow for quick maintenance of u-joints, chains, bearings, and gearboxes.

The large clean-out, service points, and access panels allow for fast and efficient auger cleaning and servicing. Tool free inspection areas include, the hopper chain cover, neck transition, boot clean-out and swing head.

Trussing & Frame

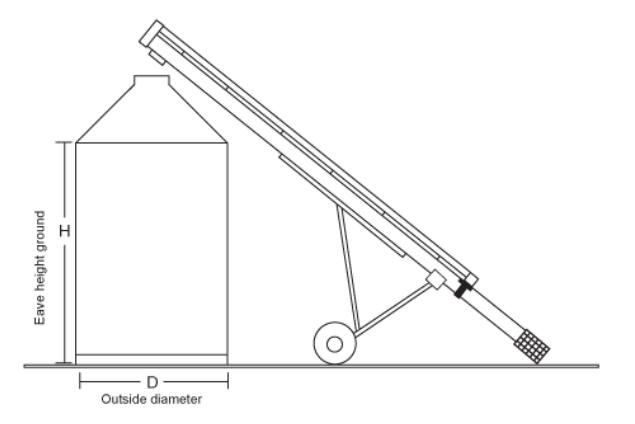

The MKX2 16 is ideal for large farm and commercial operations and is designed to maintain rigid alignment during heavy loads while reaching industry leading capacity. AGI Westfield’s commercial strength steel trussing withstands bowing to maintain

proper tube and flighting alignment, making it easier to line the auger up with the bin cap opening. The A-frame undercarriage is built to hold the auger in position and works with wide-standing extendable axles to prevent the auger from swaying or

moving once it has been positioned at the bin and the grain starts flowing.