Tractor & Skid Steer Attachment Compatibility

Determining Compatibility

Not sure if the attachment you’re looking at will fit your machine? Here’s the complete guide to attachment compatibility.

1. Attachment Connection Type

The attachment mounting plate on your machine must be compatible with the attachment plate of the attachment. Machine brands and attachment manufacturers have begun to conform to “universal” attachment plates which allow most attachments to fit most machines. There are still exceptions, however.

2. Hydraulic Couplers And Flow Rate

For attachments with hydraulic functions, the size and type of hydraulic couplers must be compatible between the host machine and attachment. The auxiliary hydraulic flow rate of the host machine must also fall within the range of accepted flow rates for the attachment. If the attachment does not require hydraulics, disregard this section.

3. Machine Lift Capacity

The weight of the attachment must not exceed your machine’s rated operating capacity (ROC). For digging and container attachments like buckets and concrete mixers, you must take into account the weight of the contents of the attachment as well.

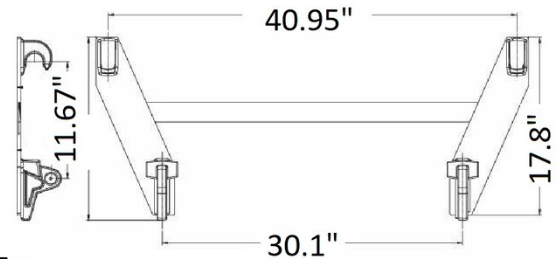

Bobcat MT

Most Bobcat mini skid steers use their proprietary attachment plate (Bobcat MT). Bobcat also has some cabbed machines that use the Bobcat MT plate (see Exceptions section above). However, Bobcat now offers the option to purchase their mini skid steers with a Mini Universal attachment plate, or the Bobcat MT plate. For this reason, we highly recommend you compare your machine’s attachment plate with our diagrams in order to determine compatibility with our mounting plate options. If you do not see a “Bobcat MT” mounting option for an attachment you’re considering, please chat with us or give us a call.

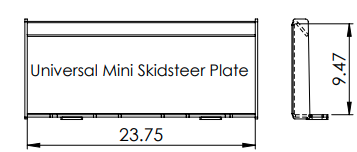

Universal Mini Skid

Most mini skid steer attachments come with a Mini Universal mounting plate. Compatible machine brands include: Ditch Witch, Vermeer, Toro Dingo, Boxer, Ramrod, Kanga and more. Bobcat now offers their mini skid steers with a Mini Universal plate, but most still feature their proprietary plate (see Bobcat MT below). For this reason, we highly recommend you compare your machine’s attachment plate with our diagrams in order to determine compatibility with our mounting plate options.

Mini ASV/Terex

ASV does not offer a stand on or walk behind style machine, but their smallest skid steers do feature a special mounting plate. Models that use this attachment plate include but are not limited to: RC-30, RT-30, PT-30. We highly recommend you compare your machine’s attachment plate with our diagrams in order to determine compatibility with our mounting plate options. If you do not see a “Mini ASV” mounting option for an attachment you’re considering, please chat with us or give us a call.

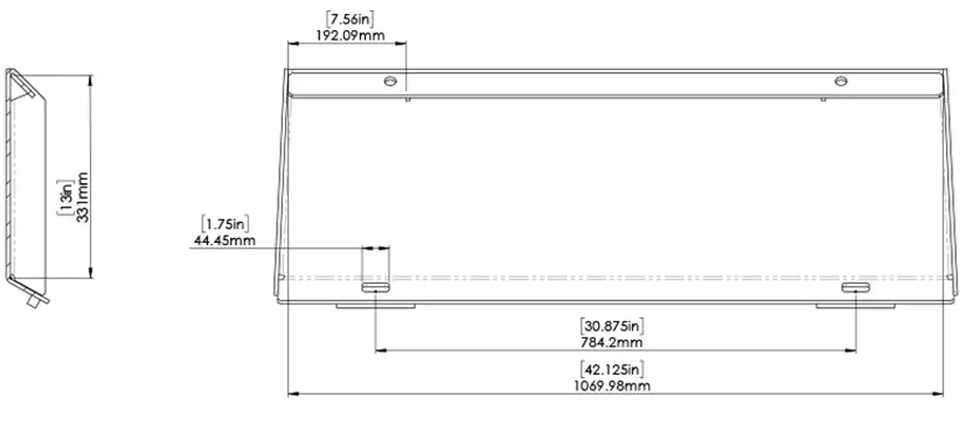

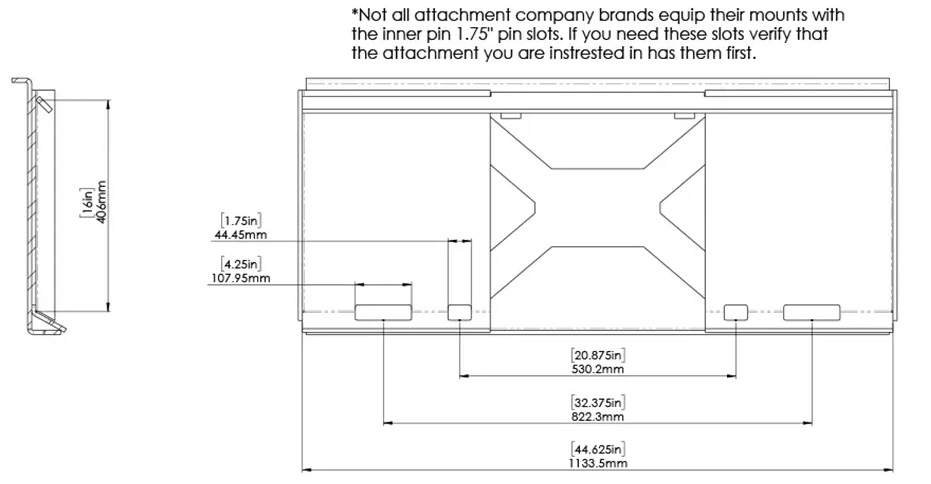

Universal Skid Attachment Connection

Modern full size skid steers & loaders feature a Universal Skid Steer attachment plate (commonly referred to as a quick attach or “quick tach”) which is compatible with standard full size skid steer & loader attachments. There are exceptions, so please use the diagram below to ensure compatibility of your machine’s quick attach.

The images below features the universal skid mounting plate, which comes included with full size universal skid attachments for sale on our website. This mounting plate is compatible with the Universal Skid “quick attach”, which is used by modern full size skid steers & loaders. This mounting plate WILL NOT fit mini skid steer (stand on / walk behind) machines of any brand.

Exceptions

In this industry there are always exceptions. There are machines that may appear to be full size (cab style), but use a mini skid steer attachment plate. Other machines are sold in multiple attachment plate configurations from dealers. We’ve outlined several common exceptions below, but please be aware that measuring your quick attach and comparing with our diagrams is the best way to ensure fitment.

Bobcat

The smallest Bobcat cab style skid steers use a Bobcat mini skid steer (Bobcat MT) attachment plate, and are NOT COMPATIBLE with the Universal Skid Steer mounting plate. Examples include Bobcat models: 310, 313, 450, 453, 463, 520, 530, 533, 553F, S70.

ASV/Terex

ASV has several popular models of small cab style skid steers that use their ASV mini skid steer attachment plate, and are NOT COMPATIBLE with the Universal Skid Steer mounting plate. Examples include: RC-30, RT-30

Hydraulic Couplers & Flow Rate

Flat Face Couplers

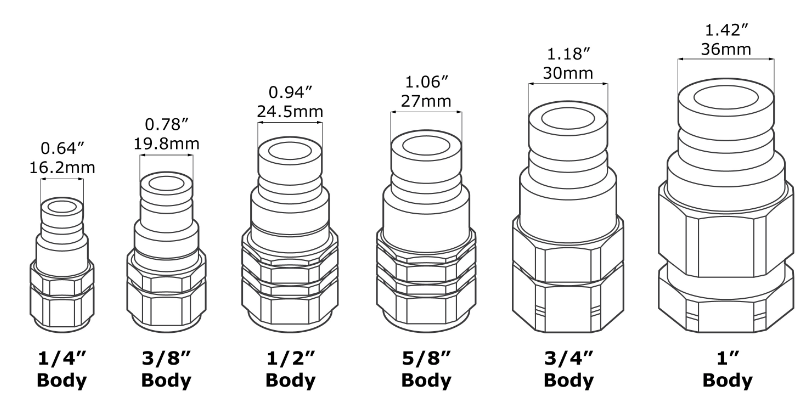

Flat face couplers are the standard couplers that most skid steers and mini excavators are equipped with these days. The male and female are both flat on the end and simply push together to form the connection. Sizes include 1/2″ for standard flow machines, 3/4″ for high flow machines (5/8″ less common for high flow machines), and 3/8″ for case drains.

Pioneer Couplers

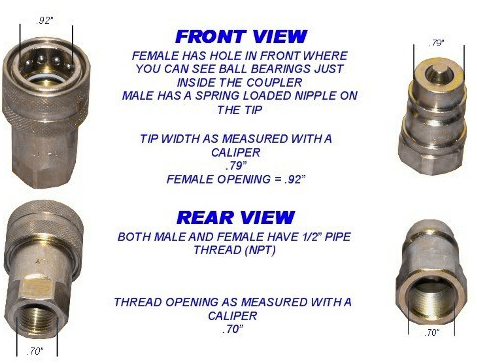

On most machines made prior to 1996, Pioneer style couplers are used. Pioneer couplers are also used on older tractor equipment. They are also used on many tractors for hydraulic connection points at the rear end of the tractor. The male end has a nipple protruding out of the end. The female end has a hole that has a ring of ball bearings around it.

Case Drain Couplers

Case drains are required on some attachments to relieve excess oil pressure from the motor seals. On these attachments there is a third hydraulic hose with a smaller 3/8” body coupler.

Typically, high flow Skid Steers and Excavators are equipped with a Male 3/8” Body coupler as the case drain coupler. In this case, when you are buying an attachment, you will select the Female 3/8” Body coupler to go onto the attachment.

If your machine is equipped with a Female 3/8” body coupler instead, then you will need to specify a Male 3/8” body coupler when purchasing these attachments.

Because the different jobs/applications that skid steers & loaders perform, a machine’s ROC may vary between 30% and 50% of its tipping load (the weight at which the machine will tip on even terrain, while stationary). 35% of tipping load is a generally agreed upon standard, but this is up to the judgement of the operator. If you are running the machine at full speed or on uneven terrain, we recommend not exceeding 35% of tipping load.