CF360 Brush Cutter | Closed Front | 70″ Path-60″ Blade Width | M650 Motor | 22-40 GPM | 2 Blades

Case Drain Required

Hoses Included – No Couplers

CF360 Skid Steer Rotary Brush Cutter Model

The rugged frame of the CF360 heavy-duty rotary brush mower houses two AR400 blades featuring a 70″ path width. The 1/4” steel deck is designed to stand up and perform in rough terrain while cutting small trees, brush, unwanted weeds and grass. The 60″ mouth of this unit is protected by a heavy-duty chain that controls flying debris, but still allows brush to easily enter. The rear of the unit is also guarded by a chain curtain so standing brush enters and mulched debris exits as you break new trails, clear ditches, construction, property sites, and other overgrown areas.

Chain curtains are standard front and rear, on the 300 series.

| Model No. | CF360 | CF372 | CF560 | CF572 | CSC744 | CSC760 |

|---|---|---|---|---|---|---|

| Available Motor Options | M450, M550, M650 | M450, M550, M650 | M450, M550, M650 | M450, M550, M650 | HS430,HS450,HS490 | C790 |

| Recommended GPM | Check Motor Options | Check Motor Options | Check Motor Options | Check Motor Options | Check Motor Options | Check Motor Options |

| Maximum Brush Size | 2″ | 2″ | 4″ | 4″ | 10″ | |

| Discharge Protection | Link Chain Curtain Front and Back |

Link Chain Curtain Front and Back |

Open Front with Push Bar Link Chain Curtain on Back | Open Front with Push Bar Link Chain Curtain on Back | Double chain on back | Double chain on back |

| Path Width | 70″ | 82″ | 70″ | 82″ | 57″ | 72″ |

| Cutting Width | 60″ | 72″ | 60″ | 72″ | 44″ | 60″ |

| Low Cutting Height | 2.5″ | 2.5″ | 2.5″ | 2.5″ | 1/2″ | 1/2″ |

| Number of Blades | 2 | 2 | 4 | 4 | 20 pcs R7000 | 30 pcs R7000 |

| Attachment Type | Universal Skid-Steer Plate | Universal Skid-Steer Plate | Universal Skid-Steer Plate | Universal Skid-Steer Plate | Universal Skid-Steer Plate | Universal Skid-Steer Plate |

| Maximum HP | Check Flow & PSI on Skid Steer | Check Flow & PSI on Skid Steer | Check Flow & PSI on Skid Steer | Check Flow & PSI on Skid Steer | Check Flow & PSI on Skid Steer | Check Flow & PSI on Skid Steer |

| Min Carrier Weight | 4,000 lb | 4,500 lb | 4,500 lb | 5,000 lb | 5,500 lb | 7,000 lb |

| System Protection | Built In Hydraulic | Built In Hydraulic | Built In Hydraulic | Built In Hydraulic | Built In Hydraulic | Built In Hydraulic |

| Dimensions (LxWxH) | 88″x72″x36″ | 90″x84″x36″ | 88″x72″x36″ | 90″x84″x36″ | 88″x75″x67″ | |

| Deck Structure | 1/4″ steel | 1/4″ steel | 1/4″ steel | 1/4″ steel | 1/4″ T1 Steel | 1/4″ T1 Steel |

| Unit Weight | 1342 lbs. | 1390 lbs. | 1540 lbs. | 1570 lbs. | 2000 lbs. | 2850 lbs. |

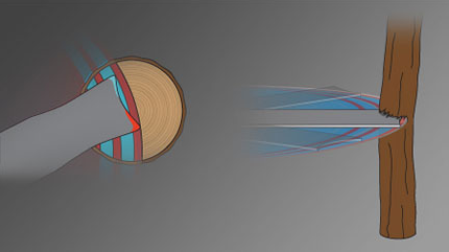

TWO CUTS PER PASS

As the rotating rotor mass throws the slasher blades at small diameter trees, the blade slices small sections away as the Brush Cutt advances forward. The curved cutting tips of the slasher blades give the Brush Cutt two cuts per pass of each blade. The leading tip takes a small bite and is immediately followed by the second tip taking another bite at 26–52 slashes per second with devastating results. Available in either 2 or 4 blade configurations the Brush Cutt’s reversible/replaceable blades are made of long lasting 1/4″ AR 400 steel.

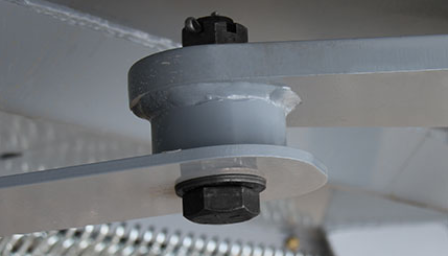

GEAR BOX

Standard on all Brush Cutt models is a relief valve. Set at 3,000 psi, this valve disengages the driveline if the hydraulic system pressure is too great, thereby protecting both the skidsteer and the Brush Cutt.

The Brush Cutt uses a bevel gearbox capable of handling up to 90HP for final drive output. More durable than conventional direct drive setups, these gearboxes prevent shocks from cutting being passed to the drive motor.

HOSE ARMOUR

Standard on all Brush Cutt models is Hose Armour. This is a tough wrap which coils around the hoses and protects them from the harsh environment of brush cutting. The armour helps to prevent any punctures from fallen brush or trees.

SLASHER BLADES

Crafted from 1/4″ AR 400 steel, the unique profile of the slasher blades provides increased cutting surface. The blade’s thin reversible profile continuously provides a sharp edge.

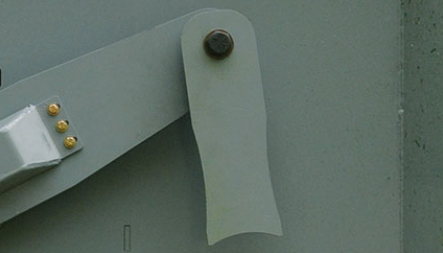

BLADE MOUNT

To secure slasher blades to the blade assembly, Baumalight uses Gr. 8 bolts capped off with castle nuts and cotter pins. The blade mount uses a fully welded collar to drop the blade; this spacing helps to reduce the blade from binding while in operation.

2-WAY MODEL

2-Way models feature a durable one piece rotor assembly. Constructed of a single 3/4″ plate of steel and finished with a slasher blade on each end. The 2-way blade models provide up to 26 slashes per second.

FRONT & REAR CHAIN CURTAINS

A heavy-duty chain curtain reduces discharge of debris. Unlike traditional chain curtains, Baumalight’s Brush Cutt uses a curtain rod setup that is free of welds. This setup allows the chain to absorb the impacts and places less strain on the welded link for longer curtain life.

SHIELD

To protect the output shaft from impact or contamination caused by debris, each model of Brush Cutt is finished off with a heavy-duty output shaft shield.

POWDER COATED FINISH

Heavy-duty construction and a durable powder-coated finish.

ANTI-SLIP STRIP

Extra traction from anti-slip strips provides improved safety as well as ease of entry and exit from the cab.

BRUSH CUTTING SIZE CHART (Brush Diameter in Inches))

| MOTOR | MOTOR TYPE |

PSI | CASE DRAIN | 12 GPM |

15 GPM |

18 GPM |

20 GPM |

22 GPM |

25 GPM |

30 GPM |

40 GPM |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor RPM | 420 | 520 | 600 | 650 | 700 | ||||||

| M450 | Roller-Vane | 2500 3000 |

Not Needed | 0.75″ 1″ |

1″ 1.25″ |

1.25″ 1.5″ |

1.5″ 2″ |

2″ 2.5″ |

Damage to motor will occur | ||

| Motor RPM | 280 | 480 | 540 | 600 | 760 | ||||||

| M550 | Roller-Vane | 2500 3000 |

Recommended | 1″ 1.25″ |

– – |

– – |

1.75″ 2″ |

2″ 2.5″ |

2.5″ 2.75″ |

3″ 3.25″ |

– – |

| Motor RPM | 260 | 300 | 370 | 480 | 615 | ||||||

| M650 | Roller-Vane | 2500 3000 |

Recommended | – – |

– – |

– – |

1.75″ 2″ |

2″ 2.5″ |

2.5″ 2.75″ |

2.75″ 3″ |

3″ 4″ |

Gearbox is a 1 to 1.46 increaser

Triple diameter capacity for felling trees

What Is A Case Drain Line ?

On most skidsteer and excavator Hydraulic systems, Hydraulic motors and pumps require a case drain line. Sometimes referred to as a third line, the case drain line will relieve any excess pressure and drain it back to your return line, then into the reservoir. Without a properly installed case drain, that extra pressure could blow a seal or damage your hydraulic line. For higher flow motors or on piston and gear motors, a case drain line is always required. Although, no matter the size of your motor, a case drain is always a good idea as it will relieve the amount of pressure on your shaft seal, helping to prolong its life. A case drain line can also increase the efficiency of your hydraulic system as it will lower the back pressure on the tank line.

Since most machines have a unique style of coupler, BaumaLight does not include a coupler on our case drain line, although they are available. If your skidsteer is not equipped with a case drain, then it can be field installed.

How Important Is A Case Drain Line ?

If we say having a case drain is critical and you operate without one, you will blow out your shaft seal. Be sure to check the motor sizing charts on our website.

Exception If You Have A Hammer Valve

There is one exception in the need for a case drain on gear motors and that is if you excavator is equipped with a hammer valve, this is a larger free flow line back to tank.

Identifying Your Case Drain Line

The following galleries show a highlighted case drain line on multiple skidsteer and excavator models.

____________________________________________________________________________________________________________________________________________________________________________

PRICES DO NOT INCLUDE SHIPPING OR SETUP – PRICED F.O.B. FACTORY

| Weight | 1430 lbs |

|---|