Baumalight MX530 40″ Brush Mulcher | Ex Mount 4-12 Ton | C510 Mtr 12-25 GPM | 64 Planer Teeth

*Must Add Excavator Adaptor To Complete – See Tab Below

*Case Drain Required

*Hydraulic Hoses & Couplers NOT Included

*PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

MX530 Fixed Tooth Mulcher for Excavator, 4-12 Ton

Our 500 series fixed tooth brush mulchers for excavators are designed to maintain and clear fence lines on farms and entry level contractor work. The 500 series Baumalight brush mulchers will efficiently mulch heavy brush and small trees and are offered with two different type of teeth. The Planer style teeth take small bites and provide the most efficient mulching and cutting. The Ripper style teeth have more of a shredding mulching action. Their v-shaped design makes them less susceptible to impacts with hard objects like stones, making them the better choice when mulching below grade and in fence lines. See our brush cutting size chart to see what limb size this excavator mounted forestry mulcher can handle. With the build in control and precision of the excavator, mulching around objects is not a problem, whether it’s in a ditch or overhead.

| Model No. | MX230 | MX330 | MX530 | MX530R | MX548 | MX548R | MX948R | MX960R | MX1160R |

| Baumalight Connection Code | A02 | A02 | A02 | A02 | A03 | A03 | A03 | A03 | A03 |

| Path Width | 38″ | 38″ | 40″ | 40″ | 62″ | 62″ | 70″ | 90″ | 90″ |

| Rotor Width | 30″ | 30″ | 30″ | 30″ | 48″ | 48″ | 48″ | 60″ | 60″ |

| Maximum Carrier Ton | 6 | 8 | 12 | 12 | 20 | 20 | 30 | 33 | 33 |

| Minimum Carrier Ton | 2 | 3 | 4 | 4 | 8 | 8 | 12 | 18 | 18 |

| Cutting Depth | Level | Level | 1.5″ Above to 1″ Below Grade | 1.5″ Above to 1″ Below Grade | 1.5″ Above to 1″ Below Grade | 1.5″ Above to 1″ Below Grade | Level | Standard level – Optional skid shoes for below ground | Standard level – Optional skid shoes for below ground |

| Holder Style | Swing | Fixed | Fixed | Fixed | Fixed | Fixed | Fixed | Fixed | Fixed |

| Cutting Style | Flall | High Speed Teeth | Carbide Tipped Bolt In | Carbide Tipped Bolt In | Carbide Tipped Bolt In | Carbide Tipped Bolt In | Double Tipped Carbide | Double Tipped Carbide | Sharpenable Planer teeth |

| Number of Cutters | 22 | 36 | 64 | 64 | 104 | 104 | 27 | 38 | 31 |

| Rotor Shaft Size | 1.5″ | 2″ | 2″ | 2″ | 2″ | 2″ | 2″ | 2″ | 2″ |

| Rotor Diameter (tool tips) | 17.25″ | 15″ | 15″ | 15″ | 15″ | 15″ | 18.5″ | 18.5″ | 18.5″ |

| Rotor Weight (with tools) | 125 lbs | 175 lbs | 300 lbs | 300 lbs | 408 lbs | 408 lbs | 617 lbs | 860 lbs | 872 lbs |

| No. of Motor | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| System Protection | Built-In Rellef | Built-In Rellef | Built-In Rellef | Built-In Rellef | Built-In Rellef | Built-In Rellef | Built-In Rellef | Built-In Rellef | Built-In Rellef |

| Unit Weight | 500 lbs | 750 lbs | 1036 lbs | 1166 lbs | 2167 lbs | 2167 lbs | 2838 lbs | 2910 lbs | 2925 lbs |

MAXIMUM BRUSH CUTTING SIZES

(Brush Diameter in Inches)

500 Series

| MOTOR | PSI | CASE DRAIN | 8 GPM |

12 GPM |

15 GPM |

20 GPM |

25 GPM |

30 GPM |

35 GPM |

40 GPM |

45 GPM |

50 GPM |

55 GPM |

60 GPM |

| RPM | 555 | 832 | 1060 | 1390 | ||||||||||

| A450 Roller-Vane | 2500 3000 3500 |

Not Needed Not Needed Recommended |

0.25″ 0.5″ 0.5″ |

0.75″ 1″ 1″ |

1″ 1.25″ 1.25″ |

1.5″ 2″ 2″ |

— — — |

— — — |

— — — |

— — — |

— — — |

— — — |

— — — |

— — — |

| RPM | 640 | 846 | 1100 | 1370 | 1600 | |||||||||

| B550 Roller-Vane | 2500 3000 3500 |

Not Needed Recommended Needed |

— — — |

0.25″ 0.5″ 0.5″ |

0.75″ 1″ 1″ |

1.25″ 1.75″ 1.75″ |

2.5″ 3″ 3″ |

3″ 3.5″ 3.5″ |

— — — |

— — — |

— — — |

— — — |

— — — |

— — — |

| RPM | 1090 | 1640 | 2050 | |||||||||||

| C508 Bent Axis Piston | 2500 3000 3500 4000 |

Critical | 1″ 1.5″ 2″ 2.5″ |

1.75″ 2.25″ 2.75″ 3.25″ |

2.25″ 2.75″ 3.25″ 4″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1190 | 1490 | 2000 | 2490 | ||||||||||

| C510 Bent Axis Piston | 2500 3000 3500 4000 |

Critical | — — — — |

1.5″ 2″ 2.5″ 3″ |

2″ 2.5″ 3″ 3.5″ |

2.5″ 3″ 3.5″ 4.5″ |

3″ 3.5″ 4.5″ 5″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1450 | 1800 | 2100 | |||||||||||

| C530 Bent Axis Piston | 2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

2.5″ 3″ 3.5″ 4.5″ |

3.5″ 4″ 4.5″ 5″ |

4.5″ 5″ 5.5″ 5.75″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1500 | 1800 | 2100 | |||||||||||

| C540 Bent Axis Piston | 2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

— — — — |

3.25″ 3.75″ 4.25″ 4.75″ |

5″ 5.5″ 5.75″ 6″ |

5.5″ 6″ 6.5″ 7″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1600 | 1875 | 2140 | |||||||||||

| C550 Bent Axis Piston | 2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

— — — — |

— — — — |

4.5″ 5″ 5.5″ 5.75″ |

6″ 6.5″ 7″ 7.5″ |

6.5″ 7″ 7.5″ 8″ |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1400 | 1630 | 1830 | 2030 | ||||||||||

| C570 Bent Axis Piston | 2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

5.5″ 6″ 6.5″ 7″ |

5″ 5.5″ 6″ 6.5″ |

6.5″ 7″ 7.5″ 8″ |

7″ 7.5″ 8″ 8.5″ |

— — — |

— — — |

| RPM | 1400 | 1570 | 1750 | 1900 | ||||||||||

| C590 Bent Axis Piston | 2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

4.5″ 5″ 5.5″ 6″ |

7″ 7.5″ 8″ 9″ |

8.5″ 9″ 9.5″ 10″ |

9″ 9.5″ 10″ 11″ |

Double brush size for “stop and chew” cutting for skidsteer models ONLY

NOTICE: Max GPM value must NEVER be exceeded on roller-vane motors or failure will occur, Piston motors run much faster before failure will occur

NOTICE: Above GPM values are under load flow estimates

900 Series

| MOTOR | PSI | CASE DRAIN | 20 GPM |

25 GPM |

30 GPM |

35 GPM |

40 GPM |

45 GPM |

50 GPM |

55 GPM |

60 GPM |

65 GPM |

70 GPM |

75 GPM |

| RPM | 1450 | 1800 | 2100 | |||||||||||

| C930 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | 3.5″ 4″ 4.5″ 5.5″ |

4.5″ 5″ 5.5″ 6″ |

5.5″ 6″ 6.5″ 7″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1500 | 1800 | 2100 | |||||||||||

| C940 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

4.25″ 4.75″ 5.25″ 5.75″ |

6.25″ 6.5″ 6.75″ 7″ |

6.5″ 7″ 7.5″ 8″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1600 | 1875 | 2140 | |||||||||||

| C950 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

5.5″ 6″ 6.5″ 6.75″ |

7″ 7.5″ 8″ 8.5″ |

7.5″ 8″ 8.5″ 9″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1400 | 1630 | 1830 | 2030 | ||||||||||

| C970 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

5.5″ 6″ 7.5″ 8″ |

6″ 6.5″ 7″ 7.5″ |

7.5″ 8″ 8.5″ 9″ |

8″ 8.5″ 9″ 9.5″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1400 | 1570 | 1750 | 1900 | ||||||||||

| C990 Bent Axis Piston |

3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

— — — — |

— — — — |

6″ 6.5″ 7″ |

8.5″ 9″ 10″ |

10″ 10.5″ 11″ |

10.5″ 11″ 12″ |

— — — — |

— — — — |

— — — — |

| RPM | Adjustable | |||||||||||||

| D97X2 Two speed (900 series) |

2500 3000 3500 4000 |

Critical | 4.25″ 5″ 5.5″ 6.75″ |

5.5″ 6.25″ 6.75″ 7.5″ |

7.75″ 8″ 8.5″ 8.75″ |

8.75″ 9.25″ 10″ 10.5″ |

9.25″ 10″ 10.5″ 11.25″ |

10.25″ 11″ 11.5″ 12.25″ |

11.25″ 12″ 12.5″ 13.25″ |

12.25″ 13″ 13.5″ 14.25″ |

13.25″ 14″ 14.5″ 15.25″ |

14.25″ 15″ 15.5″ 16.25″ |

15.25″ 16″ 16.5″ 17.25″ |

16.25″ 17″ 17.5″ 18.25″ |

Double brush size for “stop and chew” cutting for skidsteer models ONLY

NOTICE: Max GPM value must NEVER be exceeded on roller-vane motors or failure will occur, Piston motors run much faster before failure will occur

NOTICE: Above GPM values are under load flow estimates

1100 Series

| MOTOR | PSI | CASE DRAIN | 20 GPM |

25 GPM |

30 GPM |

35 GPM |

40 GPM |

45 GPM |

50 GPM |

55 GPM |

60 GPM |

65 GPM |

70 GPM |

75 GPM |

| RPM | 1450 | 1800 | 2100 | |||||||||||

| C1130 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | 4.5″ 5″ 5.5″ 6.5″ |

5.5″ 6″ 6.5″ 7″ |

6.5″ 7″ 7.5″ 8″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1500 | 1800 | 2100 | |||||||||||

| C1140 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

6.25″ 6.75″ 7.25″ 7.75″ |

8.25″ 8.5″ 8.75″ 9″ |

8.5″ 9″ 9.5″ 10″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1600 | 1875 | 2140 | |||||||||||

| C1150 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

8.5″ 9″ 9.5″ 9.75″ |

10″ 10.5″ 11″ 11.5″ |

10.5″ 11″ 11.5″ 12″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1400 | 1630 | 1830 | 2030 | ||||||||||

| C1170 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

9.5″ 10″ 11.5″ 12″ |

10″ 10.5″ 11″ 11.5″ |

11.5″ 12″ 12.5″ 13″ |

12″ 12.5″ 13″ 13.5″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1400 | 1570 | 1750 | 1900 | ||||||||||

| C1190 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

— — — — |

— — — — |

10″ 10.5″ 11″ 11.5″ |

12.5″ 13″ 13.5″ 14.5″ |

14″ 14.5″ 15″ 15.5″ |

14.5″ 15″ 15.5″ 16.5″ |

— — — — |

— — — — |

— — — — |

| RPM | Adjustable | |||||||||||||

| D97X2 Two speed (1100 series) |

2500 3000 3500 4000 |

Critical | 5.5″ 6.25″ 6.75″ 8″ |

7.75″ 8.25″ 9″ 9.5″ |

10.5″ 11.25″ 11.5″ 12″ |

12.5″ 13″ 13.5″ 14.25″ |

13″ 13.75″ 14.25″ 15″ |

14.25″ 15″ 15.5″ 16.25″ |

15.5″ 16.25″ 16.75″ 18″ |

17.5″ 18″ 18.75″ 19.25″ |

18″ 18.75″ 19.25″ 20.5″ |

19″ 19.75″ 20.25″ 21.5″ |

20″ 20.75″ 21.25″ 22.5″ |

21″ 21.75″ 22.25″ 23.5″ |

Double brush size for “stop and chew” cutting for skidsteer models ONLY

NOTICE: Max GPM value must NEVER be exceeded on roller-vane motors or failure will occur, Piston motors run much faster before failure will occur

NOTICE: Above GPM values are under load flow estimates

OPTION TO CHANGE OUT FOR 500 SERIES RIPPER TEETH

The 500 Series teeth come in two carbide tipped styles; Planer and Ripper. The Planer style teeth take small bites and provide the most efficient mulching and cutting. The Ripper style teeth have more of a shredding mulching action. Their v-shaped design makes them less susceptible to impacts with hard objects like stones, making them the better choice when mulching below grade and in fence lines. Both styles are Bolt-on replaceable for quick and easy servicing and replacement even in the field. 500 series teeth are V-Notched to work with the carbon hardened tooth holders.

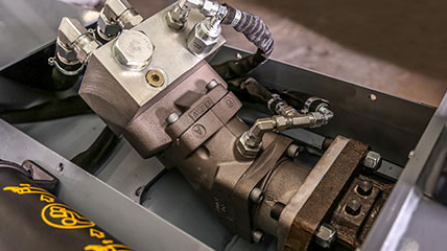

What Is A Case Drain Line ?

On most skidsteer and excavator Hydraulic systems, Hydraulic motors and pumps require a case drain line. Sometimes referred to as a third line, the case drain line will relieve any excess pressure and drain it back to your return line, then into the reservoir. Without a properly installed case drain, that extra pressure could blow a seal or damage your hydraulic line. For higher flow motors or on piston and gear motors, a case drain line is always required. Although, no matter the size of your motor, a case drain is always a good idea as it will relieve the amount of pressure on your shaft seal, helping to prolong its life. A case drain line can also increase the efficiency of your hydraulic system as it will lower the back pressure on the tank line.

Since most machines have a unique style of coupler, BaumaLight does not include a coupler on our case drain line, although they are available. If your skidsteer is not equipped with a case drain, then it can be field installed.

How Important Is A Case Drain Line ?

If we say having a case drain is critical and you operate without one, you will blow out your shaft seal. Be sure to check the motor sizing charts on our website.

Exception If You Have A Hammer Valve

There is one exception in the need for a case drain on gear motors and that is if you excavator is equipped with a hammer valve, this is a larger free flow line back to tank.

Identifying Your Case Drain Line

The following galleries show a highlighted case drain line on multiple skidsteer and excavator models.

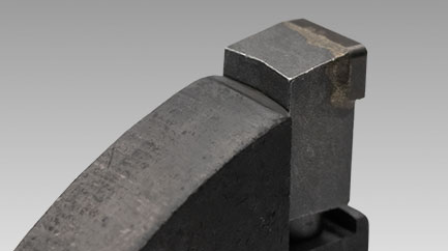

Planer Tooth Style

The Planer style tooth feeds its appetite for brush bit by bit, taking small bites and providing the most efficient mulching and cutting. Although planer style teeth are efficient, their flat profile make them vulnerable to shattering on impact with rocks and other debris. For that reason, this style of tooth is recommended for cutting applications where efficiency is more important than tooth life. Planer teeth are bolt-on replaceable for quick and easy servicing and replacement even in the field.

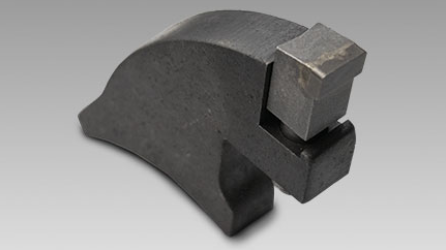

Ripper Tooth Style

Ripper style teeth is a general use tooth, offering operators a shredding mulching action. Their v-shaped design makes them less susceptible to impacts with hard objects like stones, making them the better choice when mulching below grade and in fence lines. Ripper teeth are bolt-on replaceable for quick and easy servicing and replacement even in the field.

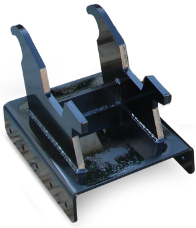

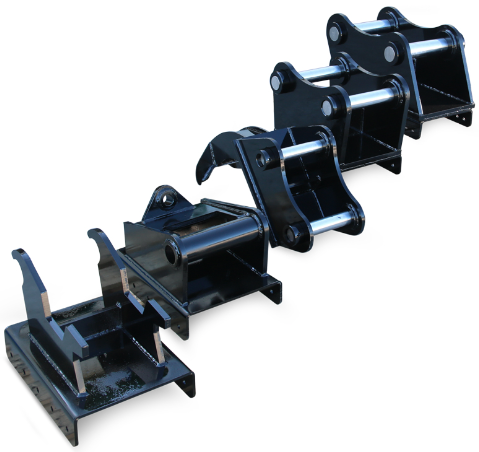

Excavator Mounting

Baumalight offers two options to mount your attachment on your excavator, blank weld-on plates & turn key custom solutions. All Baumalight excavator mounting options are manufactured in Canada and our team of experts will work with you to ensure you receive the best solution for your excavator.

Blank Weld-On Plates

The bank weld-on plate is designed for you to weld on your own ear lugs for your specific excavator mount. The bolt pattern in the plate lines up with the bolt pattern on Baumalight attachments, allowing you to bolt the attachment in place.

Turn-Key Custom Solutions

A fully customized solution, the team at Baumalight designs and builds your custom excavator adaptor for your specific excavator to ensure that the attachment is ready to go to work as soon as it arrives.

Add Connection Code

Click The Link Below To Find Your Specific D00**** Ex Mount

Add Turn Key Option That Corresponds With Your D00****

Please Note Your D00**** When Ordering

The Turn Key Pricing Includes The Connection Code Price

| Weight | 1036 lbs |

|---|