Telehawk T2 Bale Processor | Telehandler/Loader Mount | Round/Sq Bales | 13.3 GPM Min | 5733 Lb Cap

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB BV ATWOOD, KS

-Must Add Mount To Complete. Please Specify The Make/Model When Ordering. See Tab Below

-3/4″ Free Flow Return Is Required From Telehawk T2 To Telehandler/Loader, Must Utilize 3/4″ Flat Faced Couplers. Free Flow Is The Responsibility Of The Dealer/Customer.

Teagle Telehawk T2 Bale Processor

- Telehandler / Loader Mount

- 5,733 lb Capacity

- 60 l/min | 13.3 GPM Minimum

- 2,320 PSI Minimum

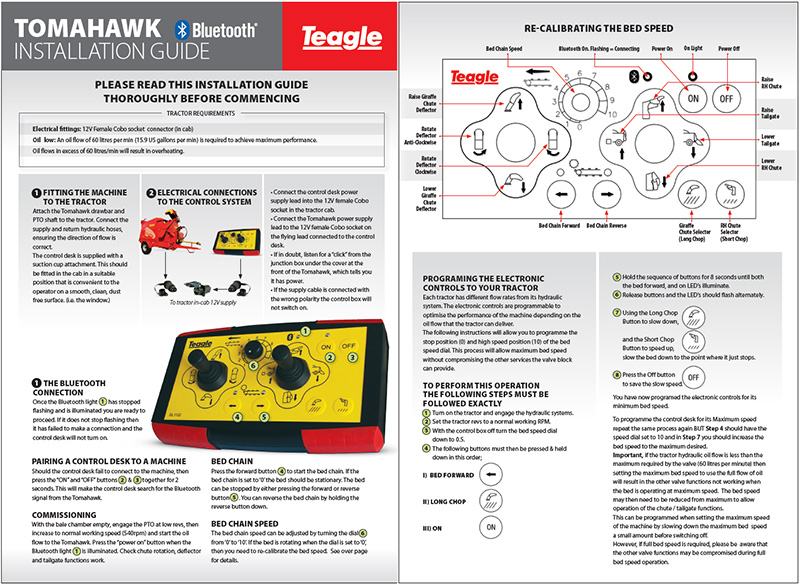

- Bluetooth Electric Controls

- 3,485 lbs

- 4′ x 5′ Dia Round Bales | 4′ x 4′ x 8′ Rectangular Bales

- Suitable For Straw & Dry Materials

- 44′ Max Spreading Distance

- Hydraulic Folding Front Lift Gate

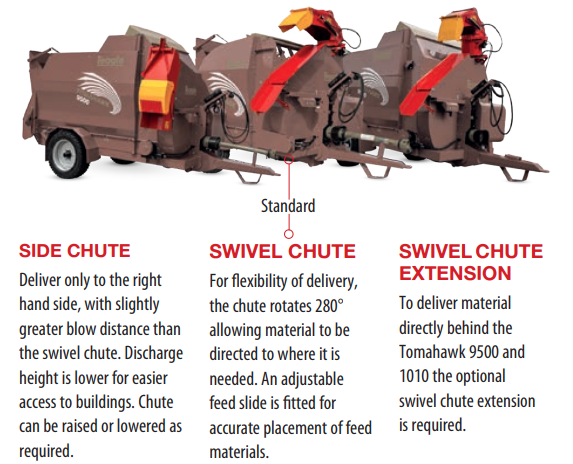

- Swivel Chute

- Crossbeater Blades (Hooks Are Available Upon Special Order)

| Model | Telehawk T2 |

| Length (Loading Gate Up) | 8’10” |

| Length (Loading Gate Down) | 13’2” |

| Width | 5’6” |

| Height | 8’3” |

| Weight (Without Mount) | 3,200 lbs |

| Blow Distance | Up To 44’ |

| Bale Capacity | 1 Round Or 1 Rectangular |

| Max Bale Size (Round) | 5’ Dia |

| Max Bale Size (Rectangular) | 4’ x 4’x 8’ |

| Lift Capacity (Min) | 6,200 lbs |

| Oil Flow (Min-Max) | 15-30 GPM |

| PSI (Min-Max) | 2,320-3,915 PSI |

Milling

- Short dry material under 20% Moisture Content

- Finished Material size from 3/8 – 5 Inches

Chopping

- Short dry material under 20% Moisture Content

- Finished Material size from 2 Inches upwards

Feeding High Moisture Content and Bedding/ Mulching Marginal Materials

- Finished Material size from 4 inches upwards

Chopping, Feeding and Bedding

- Short dry material under 20% Moisture Content

- Finished Material size from 2 Inches upwards

- Feeding High moisture content and bedding with Marginal materials

- Finished material size from 4 inches upwards

Bedding

- Short dry material finished length 4 inches upwards

APPLICATION – Milling short dry Material? High Moisture Feeding & Bedding? Chopping Short, Feeding and Bedding? Mulching?

MATERIAL – Cornstalks, Haylage, Silage, Straw, Hay, Mulch Hay, Other materials?

MOISTURE – Is any of the above High Moisture +20%?

BALE – How many bales per day to be processed and the Shape and Size?

LENGTH – Required Finished Product Length?

DISTANCE – How far is material to be distributed away from the tractor?

ATTACHMENT TYPE – Three-point hitch or trailed ?

TRACTOR – 540 or 1000 P.T.O. # auxiliary hydraulics?

LOADING – Self Loading or Loader/ Skid Steer?

Bedding

- Material saving up to 25% or more

- Use of low value materials

- Livestock Comfort & Cleanliness

- Precision for Cubicles

- Labor savings / Time Management

- Safety

- Better Manure

- Accurate Material Placement

Labor saving – one person can quickly and easily bed livestock.

Save straw – users regularly report up to 30% savings. Straw is spread evenly across the entire bedding area. Only spread as much straw as is required in each pen.

Cleaner and healthier livestock – straw is lightly shredded for improved moisture absorbance. Because straw is not chopped the bed retains its structure to provide hygienic lying areas. Straw is incorporated with the muck more evenly for improved field application.

Safer bedding – no need to enter the pen.

Alternative materials – corn stalks, soya bean straw and other low value materials can be processed.

Feeding

- Pre-Process for addition to TMR

- Dispense Silage Bales /Bunk

- Consistent Material Length*

- Sharp Ends of Material*

- Rumen Stimulation*

- Reduce Sorting

- Nutritionist Approved

One machine – two jobs bed down and feed with all Tomahawk models

Versatility – If you can bale a crop, we can shred it! Feed bunker or baled silage*, hay and root crops.*

Improve palatability – users report increased feed conversion of shredded bale silage.

Livestock cannot be selective – wastage is reduced.

Processing

Pre-process straw for mixer wagons using our unique ‘Dual Chop’ system.

Improve efficiency – reduces mixer wagon processing time.

Effective feed conversion – precision cut straw stimulates digestion.

Prevent over-processing – of silage in a Total Mixed Ration.

Process on demand – no need to stockpile.

Value for money – Impressive Payback

Existing Teagle Tomahawk owners are fully aware that the product can give an excellent return on investment in a very short time. All factors must be considered including commodity values, tractor operating costs, hourly labor rates and improved livestock welfare, all of which make the Tomahawk a hands down winner.

| Weight | 3485 lbs |

|---|