Baumalight 1P34 Stump Grinder | 30-50 HP | CAT 1 QH-Compatible | 540 RPM | 4″ Max Cut Per Pass

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB BV-ATWOOD, KS

Tractor Must Have Hydrostatic Drive

1P34 – 3 Point Hitch Stump Grinder for Small tractors

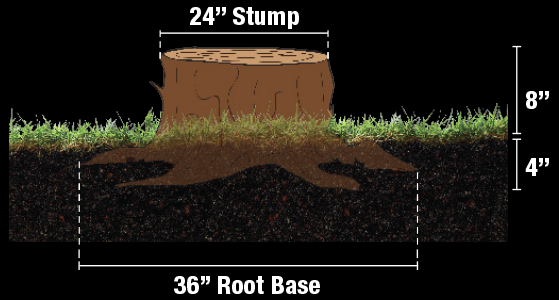

The 1P34 PTO stump grinder is a new model designed for tractors with 30–50 HP, equipped with hydrostatic drive and compatible with Category I 3PH. This tractor-mounted stump grinder features a heavy-duty 34″ rotor fitted with 40 replaceable high-speed round teeth, providing exceptional grinding performance for medium to large stumps with smaller tractors

Engineered with a cutting wheel speed of 540 RPM and delivering 803 ft.-lbs of hub torque, the 1P34 offers aggressive and efficient cutting. The tooth construction allows for 3 rotations per tooth, maximizing durability and reducing maintenance downtime. It achieves a maximum cutting depth of 4″ per pass and a horizontal cut of up to 32″, allowing you to tackle large stumps with ease.

As with other 1P series models, the 1P34 requires no hydraulic remotes, making it ideal for tractors without auxiliary hydraulics.

Weighing in at 670 lbs with a shipping width of 42″ and length of 31″, the 1P34 is a robust yet manageable attachment built for serious work. It is controlled entirely through the tractor’s PTO with no need for electric or hydraulic connections, ensuring simple setup and reliable operation.

All Baumalight stump grinders are made in Canada and are available through most farm and equipment dealers, giving you access to local service and support. If you prefer to handle your own maintenance, we also support drop-ship sales through select online dealers and back warranty service even when performed by the end user, if that’s the most convenient solution.

Every new stump grinder comes with a free 6-pack of teeth, so you’re ready for continued operation with spare parts in hand. We’ll direct ship replacements and support dealer or end-user-performed warranty repairs when appropriate.

| Model No. | 1P14 | 1P24 | 1P34 | 3P24 | 3P34 | 3P38 | 3P40 |

|---|---|---|---|---|---|---|---|

| Recommended HP Size | 20-45 | 20-45 | 30-50 | 25-55 | 45-80 | 60-110 | 60-120 |

| Maximum Engine HP | 45 | 50 | 75 | 58 | 85 | 110 | 125 |

| Maximum PTO HP | 35 | 40 | 65 | 50 | 75 | 100 | 115 |

| Transmission | Hydrostatic only | Hydrostatic only | Hydrostatic only | Any | Any | Any | Any |

| Hydraulic GPM | — | — | — | 5–25 | 5–25 | 5–25 | 5–25 |

| Rotor Size | 16″ | 24″ | 34″ | 24″ | 34″ | 34″ | 34″ |

| Number of Teeth | 12 | 34 | 40 | 34 | 52 | 52 | 52 |

| Tooth Part number | H3000 | S1000 | H3000 | S1000 | S1000 | S1000 | S1000 |

| Tooth Construction | High speed round tooth | Carbide steel bolt-in | High speed round tooth | Carbide steel bolt-in | Carbide steel bolt-in | Carbide steel bolt-in | Carbide steel bolt-in |

| Cutting Wheel Speed | 540 RPM | 540 RPM | 540 RPM | 810 RPM | 810 RPM | 810 RPM | 1000 RPM |

| Cutting Height – Above Ground | 10″ | 10″ | 10″ | 18″ | 25″ | 25″ | 25″ |

| Cutting Depth – Below Ground | 5″ | 6″ | 14″ | 8″ | 14″ | 14″ | 14″ |

| Maximum Cutting Depth – Per Pass | 2″ | 5″ | 4″ | 6″ | 9″ | 9″ | 9″ |

| Maximum Horizontal Cut | 18″ | 22″ | 32″ | 22″ | 32″ | 32″ | 32″ |

| Swing Arc | 0° | 0° | 0° | 65° | 65° | 65° | 65° |

| Hub Torque | 664 Ft.-Lbs. | 885 Ft.-Lbs. | 803 Ft.-Lbs. | 885 Ft.-Lbs. | 1475 Ft.-Lbs. | 1475 Ft.-Lbs. | 1327 Ft.-Lbs. |

| Over Torque Protection | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch |

| Hitch | Cat I | Cat I | Cat I | Cat I or II | Cat II | Cat II | Cat II |

| Quick hitch compatibility | Yes | Yes | Yes | No | No | No | No |

| No. of Remotes Required – Hydraulic | 0 | 0 | 0 | 1 or 2 | 1 or 2 | 1 or 2 | 1 or 2 |

| Requires 12 Volt DC | No | No | No | No | No | No | No |

| Input Speed | 540 | 540 | 540 | 540 | 540 | 540 | 1000 |

| Unit Weight (Shipping) Lbs. | 360 | 450 | 670 | 920 | 1231 | 1113.80 | 1280 |

| Width (Shipping) | 36″ | 36″ | 42″ | 42″ | 48″ | 48″ | 48″ |

| Length (Shipping) | 30″ | 30″ | 31″ | 49″ | 54″ | 54″ | 54″ |

HIGH SPEED TEETH

The concave shaped carbide tip of our High Speed Teeth provide aggressive cutting action by chipping the brush bit by bit. This round tooth is 3 teeth in 1. Simply loosen the lock nut and rotate the tooth to a fresh, sharp cutting edge. This can be done three times, extending the life of each tooth.

MORE TEETH

The high number of teeth means that each tooth needs to do less work. Each of the Stump Blasters teeth only need to make a small cut, because the work is shared by more of our rugged teeth they last longer and usually only require 2 or 3 replacements at a time. The bolt-on designed teeth allow for straightforward replacement.

ROTOR

The massive ⅝” thick steel rotor provides the back bone for the Stump Blaster cutting system. It’s the anchor for the carbide tipped teeth. For smooth operation it’s important that the rotor remains solid, with no flexing. The rugged rotor also provides the Stump Blaster with the extra momentum needed when the grinding is tough, making sure the Stump Blaster can power through the hardest stumps.

| 1P14 | 12″ x 12″ cut

1P14 only must be mounted on a hydrostatic drive tractor |

| 1P24 | 12″ x 12″ cut

1P24 only must be mounted on a hydrostatic drive tractor |

| 1P34 | 12″ x 12″ cut

1P34 only must be mounted on a hydrostatic drive tractor |

| 3P24 | 12″ x 12″ cut

|

| 3P34 | 12″ x 12″ cut

|

| 3P38 |

|

| 3P40 | 12″ x 12″ cut

|

| Weight | 670 lbs |

|---|