Buffalo Roller Mill / 540 PTO / Trailer / 1.35 Diff Dr. / Hyd. Inlet Auger / 4′ Dis Pan / 5 GPI

Henke Buffalo KwikKracker 1254 Roller Mills

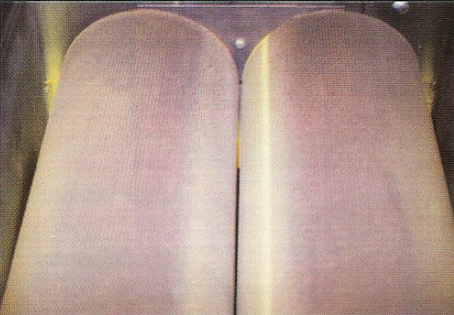

- 12″ Roll Diameter

- 54″ Roll Length

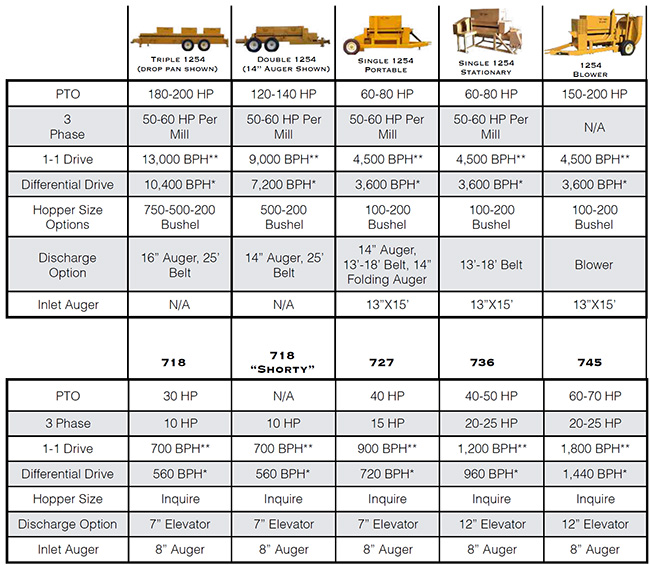

- Up To 4,500 BPH / 126 TPH Corn Capacity

- 1.35 O.D. Differential Drive

- 540 PTO Drive Kit (80-150 HP Min.) W/Shield/Mtg. Kit

- Trailer

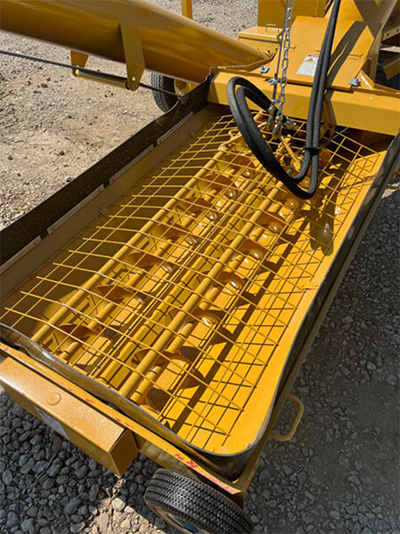

- Inlet Auger Low Profile Hopper (13″ x 15′) W/Hyd. Drive & Lift

- Auger Pan Discharge | Extends 4′ Past The End Of The Mill

Options Or In Lieu Of

- 1000 RPM PTO

- Electric Drive

- Safety Chain Kit For Trailer

- Various Groove Patterns (Call For More Info)

- 1:1 Drive Ratio

- High Moisture Grain Kit

- 100 Bu Inlet Hopper

- 18″ x 8′ Conveyor Discharge

- 14″ Folding Auger Discharge | 12’6″ Discharge Height

- Stationary Mount

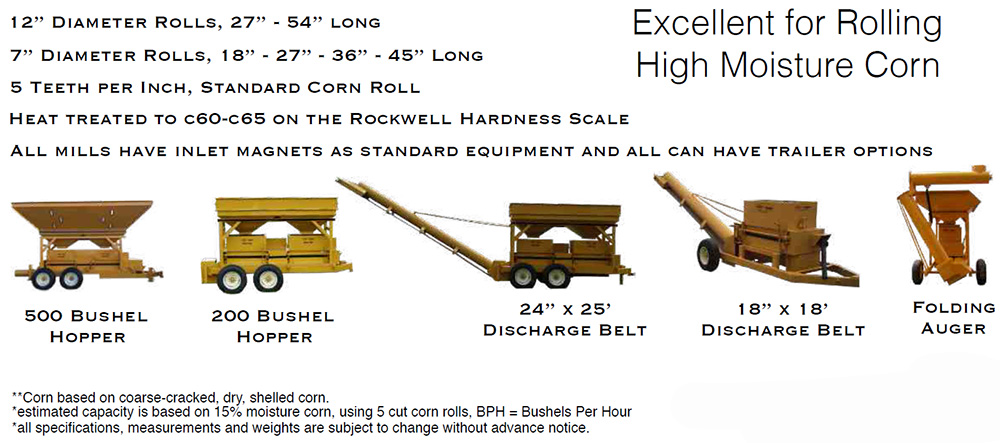

Henke Buffalo KwikKracker Roller Mills

Built with the operator in mind, our Roller Mills are easy to adjust, easy to operate and easy to maintain.

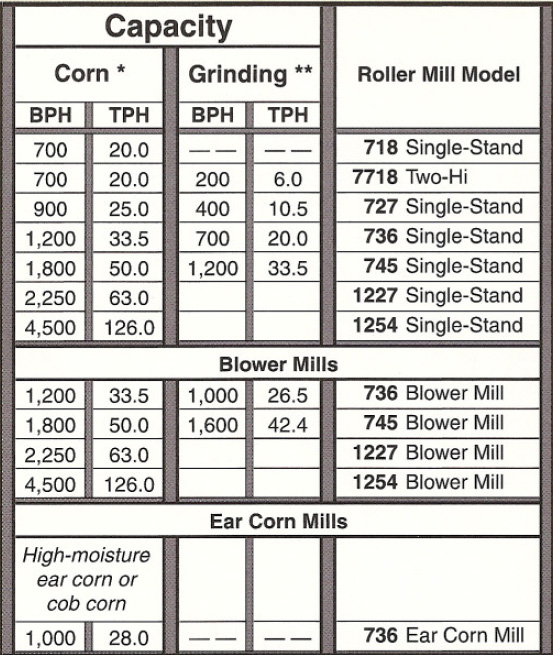

- Capacities: 700 to over 4500 bushels per hour – among the highest capacity on the market

- Easy-adjustment lever for setting the rolls for coarse or fine crack

- Each Roller Mill comes with magnets as standard equipment on the inlet hopper to prevent metallic debris from getting into the gain

- Rolls are heat-treated to Rockwell C-62 – some of the hardest in the industry

- Henke Roller Mills come in a wide variety of roll sizes from 18″ to 54″ in length

- Easy access shields for ease in service and maintenance

- Standard one-to-one ratio drive produces a finished product with minimum fines; optional differential drive is also available for a finer rolled finished product

- Two-high Roller Mills are available featuring coarse-corrugated top rolls and fine-corrugated bottom rolls to allow for additional particle size reduction

- Trailer-mounted models allow conveniently moving the mill to various processing sites

- Stationary-mounted models allow permanent installation