Maschio SC-230 93″ Tiller | CAT 2 Stand. – CAT 3N Avail | 90-170 HP | 54 Blades

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

*Standard CAT 2 Unit Is NOT Quick Hitch Compatible

*Packing Charge $160

*Please Specify PTO When Ordering

- 540

- 21 Spline 1-3/8″ 1000

- 20 Spline 1-3/4″ 1000

Maschio SC Tillers

Note: It may take more than one pass to achieve the maximum tilling depth in virgin ground

- 540/1000 rpm PTO gearbox

- Rotor revolutions PTO 540 rpm (3s): 133-162-220

- Rotor revolutions PTO 1000 rpm (3s): 181-246-300

- Slip clutch PTO shaft(1” 3/8 Z6 tractor side yoke)

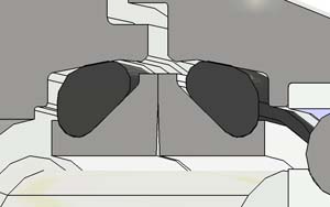

- Heavy-duty rotor hub:

- – Duo-Cone metal face seals

- – Oil-bath – Heavy-duty SKF spherical roller bearings

- Side gears drive in oil bath

- Universal three point hitch, cat. II^

- Swinging front hitches

- Rear PTO

- 6 blades per flange (side blades are always mounted inwards)

- Long multi-bends rear levelling doors with down-pressure double springs

- Pair of skids

- Third point linkages standard on 280 and wider versions

- Version with Ø 22 in. rotor available upon request

- Version with outwards mounted side blades available upon request

Wider rear rollers for optimal seedbed preparation

The rear rollers are wider than the rotor allowing a perfect seedbed refinement and levelling.

Windingshape levelling bonnets

The levelling bonnet comes as standard. it is adjustable by a mechanical jack in order to ensure a perfect levelled and smooth seedbed. The sturdy springs act as shock absorber and they increase the machine stability at work.

Low maintenance

The new Duo-Cone sealing system guarantees reliability without maintenance. You can achieve at least 50% longer life from the Duo-Cone system than standard sealing systems in the most demanding working environments.

The sealing system is completely waterproof or “amphibious” allowing the rotor and bearing to run in its own oil supply, this allows the rotor to work and be reliable in the dustiest of environments or even work immersed in water and yet the seals will still prevent water and dust ingress into the rotor and hubs.

Side gear drive in oil-bath

3 heavy duty gears in oil-bath ensure high performance even in heavy working conditions.

Long life bearings

Special roller bearings with “barrel” self-orienting casing are the best solution to have both resistance (+30% compared to tapered bearings) and to be easy in use. For their installation no pre-load operation is required; their self-aligning capacity is the key for an outstanding reliability in any working condition!

Multispeed gearbox

Working speed could be easily set by changing the gears inside the gearbox. The user may select the most suitable rotor rpm according to soil conditions.

| VERSION | BLADES NR. | POWER NEEDED (HP) | WORKING WIDTH (FT.) | WORKING DEPTH (IN.) | TOTAL WIDTH (FT) |

|---|---|---|---|---|---|

| 230 | 54 | 90-170 | 7½ | 10 | 8 |

| 250 | 60 | 100-170 | 8 | 10 | 9 |

| 280 | 66 | 110-170 | 9 | 10 | 10 |

| 300 | 72 | 130-170 | 10 | 10 | 10½ |

Is This A Right Hand Or Left Hand Tiller Blade?

Step 1: Remove the tiller blade from the tiller.

Step 2: Hold the tine so that it dangles from the bolt holes.

Step 3: Holding the blade in front of you, turn it so that the cutting edge faces you. If the blade curves to the left, it’s a left-hand blade.

| Weight | 2002 lbs |

|---|