Remlinger 5′ No-Till Drill | CAT 2/3/3N – QH Comp | Large, Small, & Native Hoppers | 8 Openers – 7.5″ Spaced

*PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

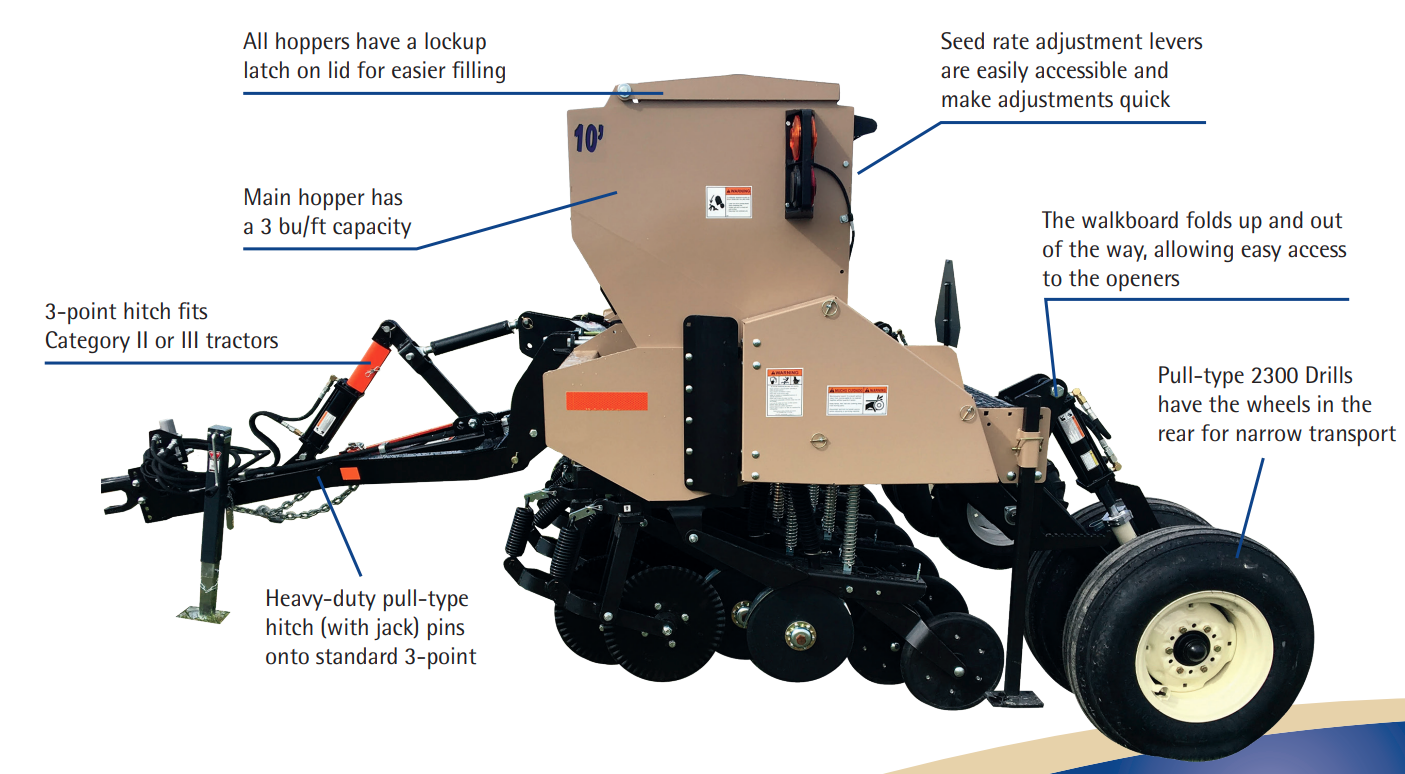

Remlinger 2300 Drills

Remlinger Manufacturing Co. offers their 2300 Series line of No-Till Drills, in 5′ through 15′ sizes. The Remlinger 2300 was designed to be a cost-effective way to accommodate a wide variety of applications. This design produces a machine with enough strength and flexibility to carry you through your various seeding operations. Traditional seed placement, pasture renovation, native grass plots & small seed cover crops to name a few. The basic drill, with the large seed hopper only, can be used as a no-till drill in the traditional sense. It is capable of drilling a wide variety of beans, peas, wheat and larger grass seed. This basic setup can also be used to renovate existing pastures or create new pasture areas. The addition of the native grass seed hopper gives your basic drill more flexibility. The hopper comes standard with aggressive internal agitators to keep the fluffy seed from bridging and feeds them into saw toothed picker wheels. The picker wheel act as the seed meter. This hopper can be used to create native grass plots for wild life, help prevent erosion and return un useable farm ground back to its natural state. Finally, a small seed hopper can be added to the basic drill setup. The small seed hopper allows you to drill a wide variety of alfalfas, clovers, ryegrass and radishes. These seeds are normally used as a cover crop providing nutrients, loosening of the soil and weed control. The 5′ pull type drill is excellent for planting cover crops between rows in a vineyard. The native grass and small seed hoppers can be used in any combination with the basic drill setup. Each can be added at any time. The Remlinger 2300 Grain Drill is capable of performing a wide array of applications across your farming operation. Try it out and we bet that you will agree.

RMRT050875NT213 Unit Includes

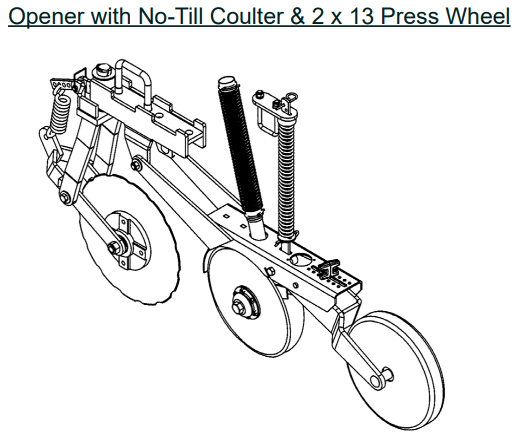

- 8-Openers With 7 1/2″ Spacing

- 2″ x 13″ Press Wheels

- Large Main Hopper, Small Seed Hopper, & Native Grass Hopper

Model 2300 Drill Features

- No-Till Or Conventional

- Convert To Conventional From No-Till By Pulling 1 Pin

- Main Hopper – 3 Bu/Ft Capacity

- Small Seed Hopper .27 Bu/Ft Capacity

- 7-1/2″ Spacing

- Acre Meter

- Precision Fluted Meter

- 3 Bu/Ft Welded Hopper

- 2 Bu/Ft On 5′

- Weather Tight Lid

- Double Disc True “V” Openers

- Folding Metal Walk Board w/ Step

- Gage Wheels – 15″ Tires & Wheels

- SMV & Reflectors

- Light Package

- Adjustable Seeding Rates

- Staggered Mounting Brackets

- Seed Level Indicator Glass

- 2 x 13 Press Wheel

- D-Handle Depth Adjustment

- 15″ Ripple No-Till Coulter

Row Spacing

Row spacing can be changed easily from your current width to any row width you desire, within the limits of the over-all drill width. Determine the row width desired. Each opener unit may be easily moved right or left on the pull bar by simply loosening two U-bolts. If you do not wish to use all attached opener units, cap off the un-needed meters. Optional meter covers are available.

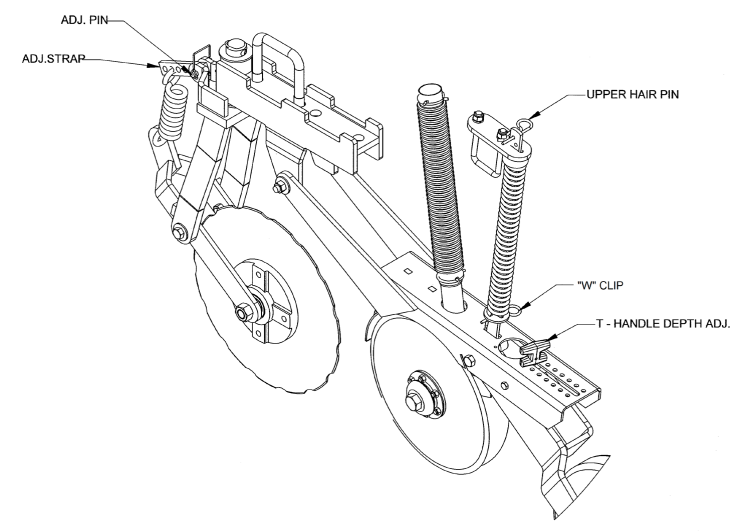

No-Till Coulters

• Start with the adjusting pin in the 2nd hole from the top of the adjustment strap. This should be suitable for most conditions.

• If the coulters do not go to the desired depth, move the adjusting pin to the third hole in the strap for more depth, or to the first hole for less depth.

• When No-Till drilling, the fluted coulter should be set approximately to the depth of the seed or slightly deeper.

• The lower the frame height, the more down pressure will be on the No-Till coulters and openers.

Opener Down Pressure Springs

• Lower “W” Clip: The lower “W” clip sets the amount of down pressure on each opener. Start with it in the bottom hole (least down pressure). If more down pressure is required to push the openers in the ground, such as behind the tractor tires, move the lower “W” clip up one hole at a time.

• Remember you can only exert as much down pressure as there is weight on the drill, if increasing spring down pressure does not help push the openers in the ground, additional ballast may have to be added, or the grain tank may have to be kept full.

Opener T-Handles

The T-Handle on the opener sets the press/gauge wheel depth. This is what determines how deep the seed is planted. Start with the T-Handle in the middle of its range. To increase planting depth, move the T-Handle backward. To decrease planting depth, move the T-Handle forward.

Additional Weight

The success of No-Till drilling is often dependent on the proper machine set up in the field. In many cases, the weight of the drill is critical to the proper operation of the drill and since the weight of the drill is the ground penetrating force, the proper distribution of this weight is absolutely essential. The weight must be distributed to three main areas: coulters, openers and press wheels. If too much of the weight is placed on the coulters, it is possible that there won’t be sufficient weight left to create proper opener penetration and press wheel pressure. If the desired frame height cannot be maintained, additional weight is probably necessary. Up to 100 lbs. additional weight may be added per opener. There may be some situations where the ground/trash conditions are so tough that the weight of the machine is not adequate to obtain proper penetration even when the allowable added weight is added to the machine.

Ground Preparation

The effective use of a No-Till drill is dependent upon proper field preparation. Consideration should be made long before the ground is to be planted about insuring a properly prepared field that will be suitable for No-Till drilling. In the case of wheat or rice ground, tire ruts and poor straw distribution should be avoided. For best results, the straw should be chopped and spread evenly as the straw is harvested. Trash problems can be avoided by cutting the crop higher off the ground and herbicide application is not blocked by lying straw. The ground should be relatively smooth in contour and free of large clods or ruts. A Remlinger drill will perform best on relatively smooth ground. With smooth ground, the spring pressures will be consistent across the width of the machine. Check to be sure the press wheels remain in contact with the ground and with the T-Handle. It should make the soil over the seed firm, but not too firm. Over packing the seed bed can result in poor stands as the plant may have trouble pushing out of the packed soil. If the press wheel doesn’t remain in contact with ground and T-Handle, more down pressure is required. Whenever possible, plant in soils with plenty of moisture (not muddy). Soils with higher moisture contents have considerably less shear strengths than the same soils at lower moisture content. Therefore, many penetration problems can be avoided by simply planting at the proper moisture content. Experience will teach each operator the proper moisture content for his particular soil.

Ground Speed

The recommended ground speed for drilling is 4 mph. In smooth, well prepared soils, speeds in excess of 8 mph have been successful. The main concern is to give the springs an opportunity to successfully maintain contact between the ground, coulters, openers, and press wheels. Excessive bouncing causes inconsistent seed rates and seed depth and unnecessary wear to the machine. Ground speeds can be tailored to each individual situation. Rough terrain, ground hardness and trash are the main consideration in adjusting ground speeds. To check opener depth, the press wheel should be resting firmly on the ground. The opening made by the opener should be closed by the press wheels. To check the down pressure, walk behind the drill while it is in motion. The press wheels should stay firmly on the ground. If the press wheels are bouncing off the ground, more down pressure is needed or the drill needs additional weight.

| Weight | 2295 lbs |

|---|