Tar River 6’1″ Drum Mower | CAT I & 2 | 35 Min HP | 3 Blades Per Drum

*PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB BV ATWOOD, KS

Tar River Drum Mowers

Tar River Implements is proud to introduce the new line of Drum Mowers. With very few moving parts, low maintenance and a heavy built frame, the Tar River Drum Mower is a great economic alternative to a Disc Mower or Sicklebar Mower while still giving a high quality cut.

The Tar River Drum Mower is designed to provide reliable mowing in all types of conditions and easily cuts through tall and thick grasses.

Each unit comes with a toll to change the blades & an extra set of blades.

Features & Benefits

• Heavy Duty A-Frame

• 3 Blades Per Drum

• Compensation Spring “Break-Away” System

• High Blade Tip Speed for Smooth, Fast Cutting Efficiency

• 4 V-Belts

• Easy & Quick Blade Change

• No Hydraulics Necessary

• Few Moving Parts & Easy Maintenance

• Great Alternative to Disc Mowers & Sicklebar Mowers for Small Hay Producers

• Easily Cuts Through Tall & Thick Grass

• Designed for Reliable Mowing in All Conditions

| MODEL | NO. OF DRUMS | BLADES P/ DRUM | CATEGORY HITCH | WORKING WIDTH | MIN. RECOMMENDED TRACTOR WEIGHT | MIN. HP | WEIGHT | HYDRAULIC LIFT KIT OPTION AVAILABLE |

|---|---|---|---|---|---|---|---|---|

| BDR-135 | 2 | 2 | Cat. 1 | 4′ 5″ | 2100 lbs | 20 HP | 661 lbs | n/a |

| BDR-165 | 2 | 3 | Cat. 1 & 2 | 5′ 5″ | 2600 lbs | 28 HP | 794 lbs | Yes – BDR-A60 |

| BDR-185 | 2 | 3 | Cat. 1 & 2 | 6′ 1″ | 3900 lbs | 35 HP | 893 lbs | Yes – BDR-A80 |

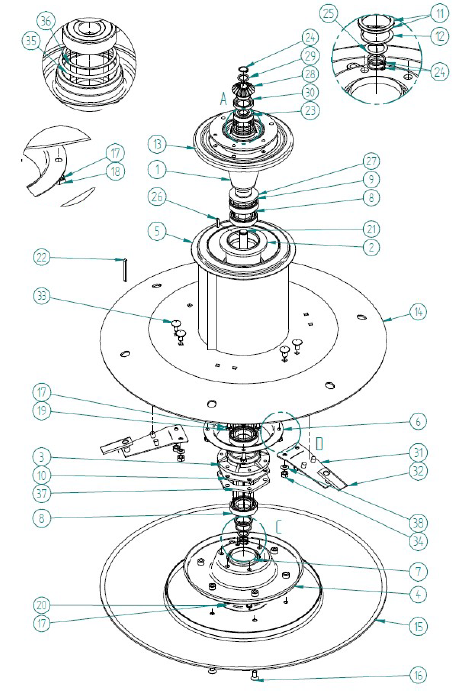

Adjusting The Height Of Cut

Each unit comes with a 8mm standard height spacer ring which gives the unit a standard cut height of 40mm. You may add, subtract, or substitute spacers to achieve your desired height of cut. Cut heights must stay between 32mm – 48mm.

To adjust the cutting height, the following must be done:

- Position the mower to the transport position and lift it to the upper position.

- Set the tractor’s handbrake and disengage the tractor’s engine.

- Secure the mower from falling with a chain and an additional support placed under one of the stump jumper disks.

- Unscrew the bolts M12x25 (Position 1 in Drawing 3) and disassemble the stump jumper (Position 2 in Drawing 3).

- Unscrew the resistance disc bolts (Position 3 in Drawing 3) M12x30 and take it off.

- Adjust the cut height and assemble it in the reversed order.

- Perform the adjustment in the other stump jumper disc repositioning the support.

| Weight | 893 lbs |

|---|