WCX 1535 Straight A Frame Conveyor | Pinch Top Drive (Elec Or Hyd) | 15″ Belt | 35′ Length | 6,000 BPH

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

*Call For Back Freight

*Must Add Drive To Complete

Shipped Complete With

• 27″ x 38″ collapsible hopper with 10″ clearance

• 35′ long; 10″ diameter 14 GA tube

• 15″ 2-ply rubber belt coupled with nylon slider backing and alligator lacing for added endurance

• Durable poly deflector hood provides excellent cushioning for delicate seeds and commodities

• Heavy duty 1-1/4″ bearings and adjustable rollers

• Four-bolt hubs and taper wheel bearings make unit suitable for towing

• Removable tow hitch allows easy maneuverability during operation

WCX1500 Belt Conveyor Series

• Weather guards are standard on all conveyors

• Maximum service angle at 30-degrees

• All belts are made of 2-ply Chevron nylon slider backing

• Plastic hood and collapsible canvas hoppers provides excellent cushioning for fragile materials

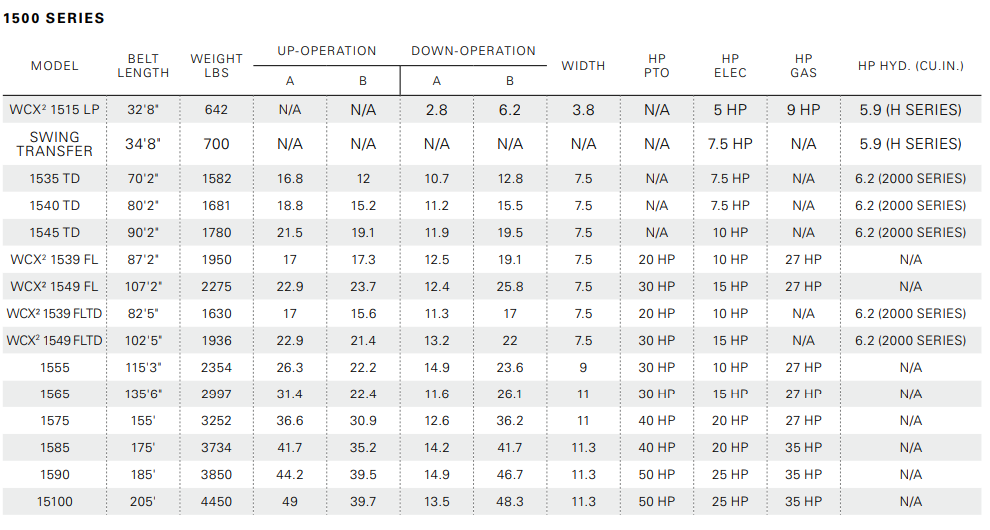

1500 Series

10″ TUBE | 15″ BELT

• Capacity rated up to 6,000 bph

• Available in lengths from 35′ to 100′

• 10″ diameter tube

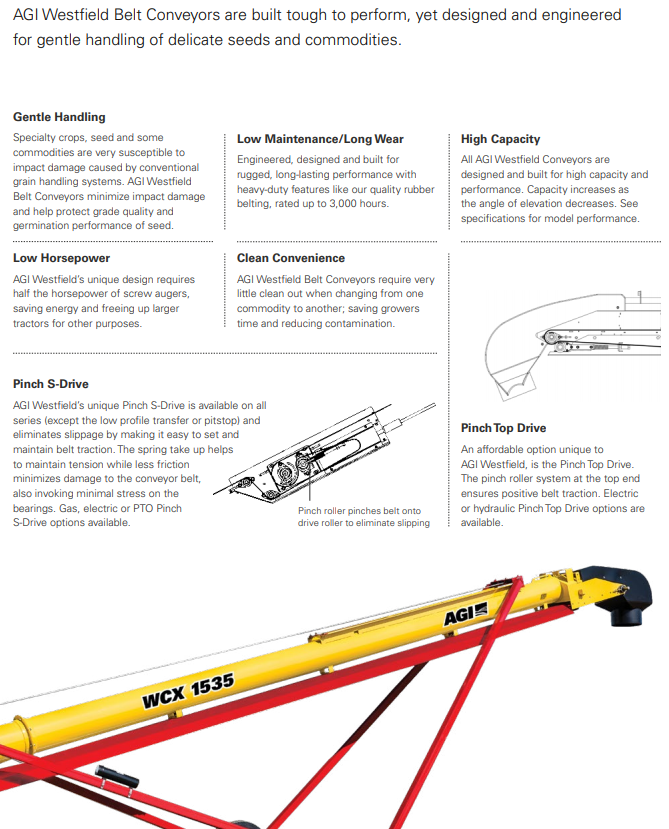

FEATURES

• A-frame undercarriage on 35′- 55′ lengths

• Hydraulic scissors lift on 65′-100′

• Offers greater reach and bin clearance

• Cable trussing on the 55′-100′ models

• Extendable axles on 85′-100′ models

• Optional self-propelled kit available

Must Add Electric Drive Kit, Motor, & Motor Pulley

If Selecting A Single Phase Motor, A Wiring/Switch Box Kit Must Also Be Added

Westfield Conveyor Calculator

Find A Conveyor That Best Fits Your Grain Handling Needs. Use The Westfield Calculators To Help You Determine:

- What Length Of Conveyor Will Best Complement Your Bin Height

- How Much Ground Length Is Necessary To Ensure Your Conveyor Will Reach The Desired Bin Height

| Weight | 1582 lbs |

|---|