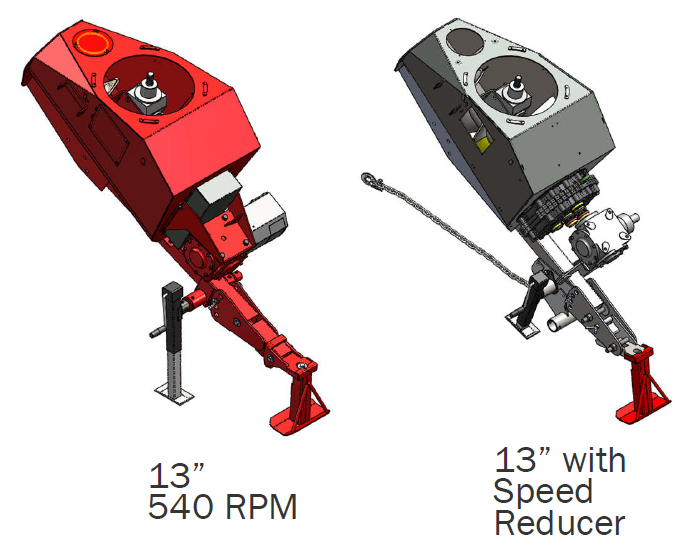

Westfield MKX2 13″ X 114′ Auger | Low Profile Hopper | 15′ Swing Tube | 540 PTO | Up To 11,000 BPH

*PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

Shipped Complete With

- Shielded 540 CV-PTO driveline equipped with overload shear bolt(s) – 1000 PTO Avail

- Dual hydraulic lift cylinders with improved shut – off valve

- Low Profile Hopper

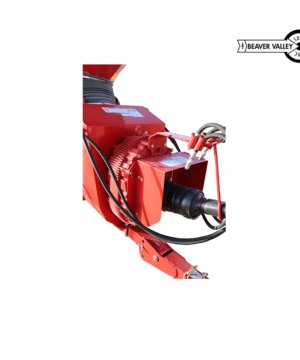

- Hopper lift system with 5:1 winch

- 16″ tires mounted on rims are standard

- Hydraulic tractor end couplers

Low Profile Hopper –

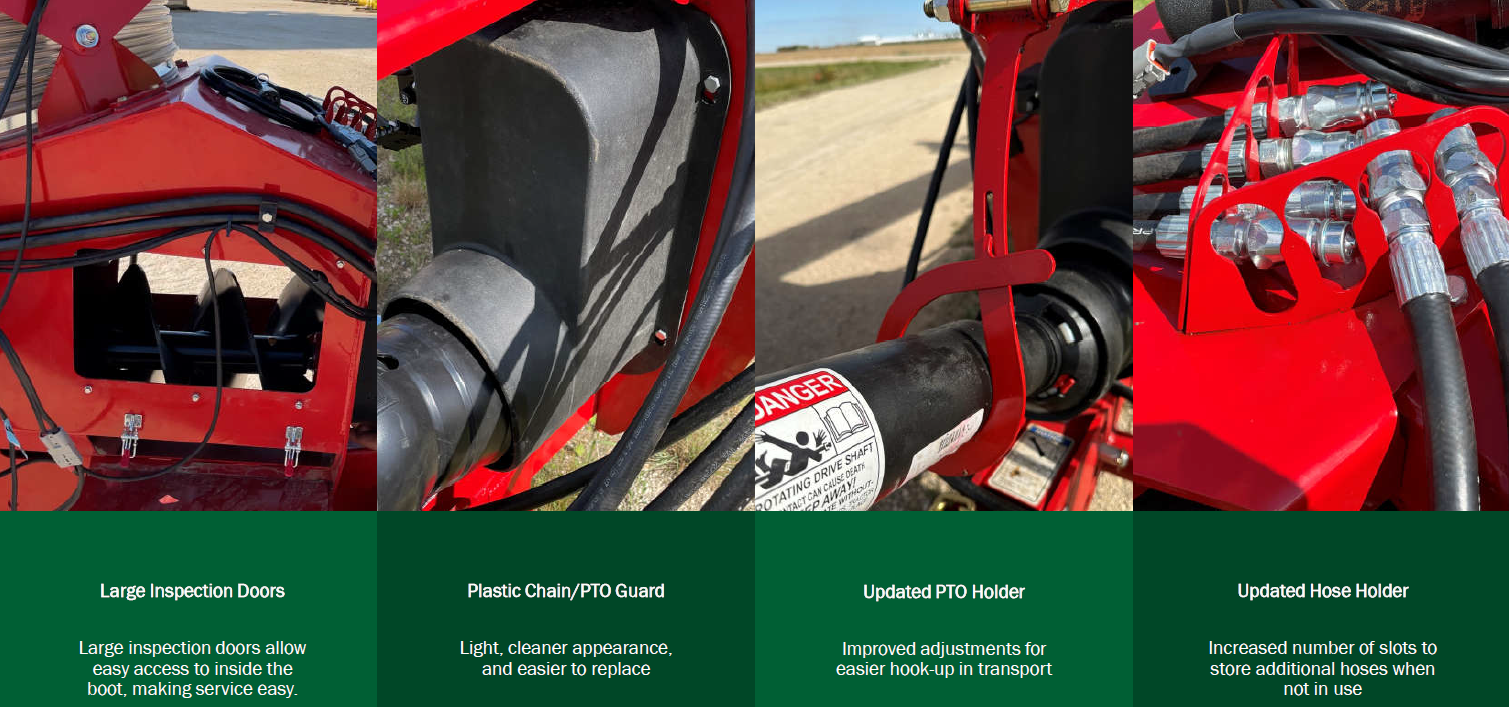

Redesigned Boot

-

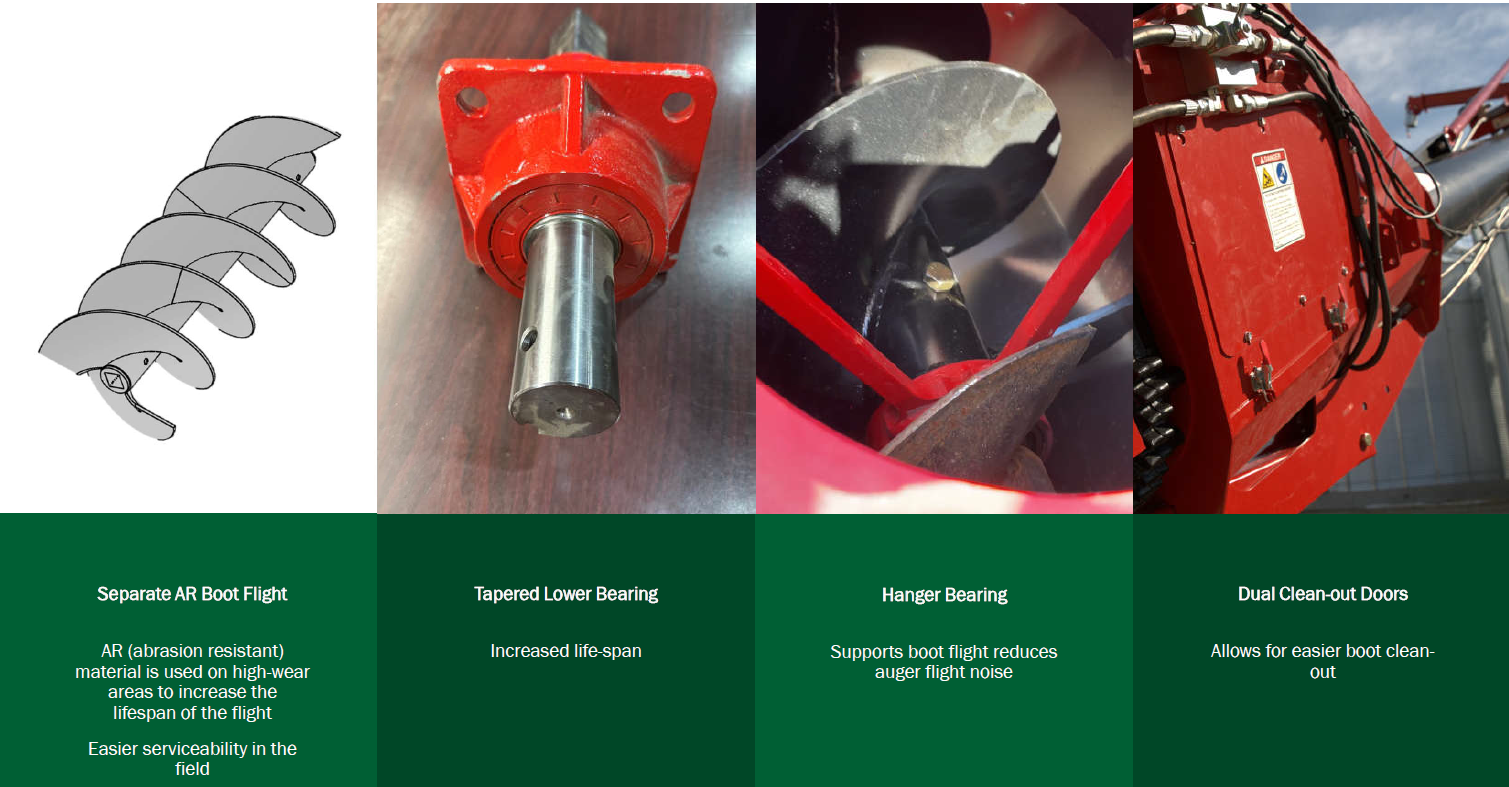

- Separate boot flight with removable shafts (10”, 13”, and 16”)

- AR boot flight standard (13” and 16”)

- Hanger bearing to support boot flight (13” and 16”)

- Tapered lower bearing for increased life span (13”)

- Clean-out doors on both sides of the boot (13”)

- Updated PTO and hose holders (13”)

Auger Lean Prevention

-

- Vertical stabilizer brace between lower frame arms to lock and prevent tube from rotating in transport position

- Stays engaged through lift assist range of motion as auger is raised and then disengages

- Nylatron GSM material provides a low friction surface to prevent binding

- Included on MKX² 13” a-frame augers equipped with X-Tend or X-Over swings

Cylinder Updates

-

- Commonize cylinders to use with various auger sizes

- Fewer cylinders required to stock

- Added ram guide to MKX²1073 cylinder to ensure cylinder lifts straight

- Change from internal check valve to external check valve

- Easier to access/service/replace in the field

- Easier to access/service/replace in the field

- Commonize cylinders to use with various auger sizes

X-Over

-

- New mechanical drive

- No hydraulic motor

- Factory set auger flight and belt speeds

- Redesigned belt interface and added seals to limit leakage

- Reduced belt width from 23-1/2” to 20” and still maintain the capacity to match 13” augers

- Redesigned, reinforced drive-over deck and ramps to better handle multiple drive-overs

- New mechanical drive

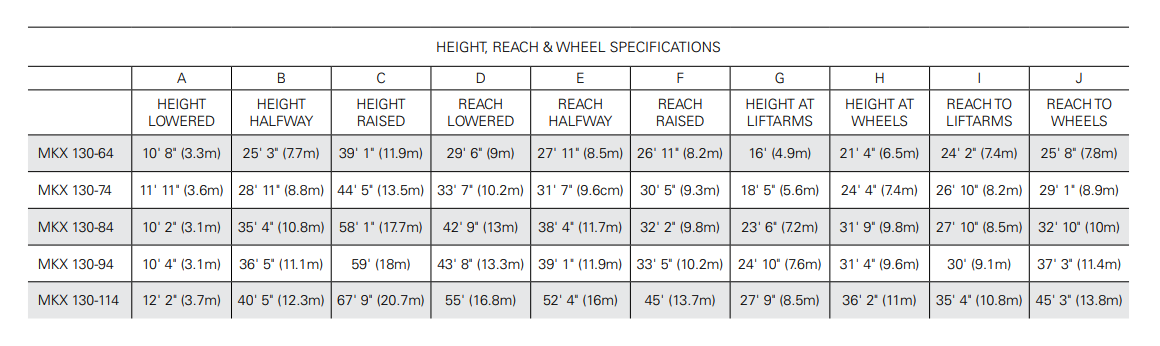

MKX2-130 Series

13″ Diameter | 64′ – 114′ Lengths | Up To 11,000 bph

The MKX2 Series features over 75 proven performance enhancements, specializing in ease-of-use and serviceability. The MKX2 Series is available in 10″, 13″ and 16″ tube diameters and lengths from 53′ to 125′ and capacity up to 23,000 bph.

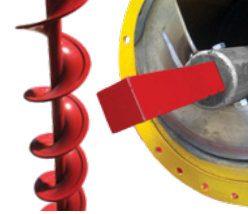

Built Strong & Lasts Long

Westfield developed Wear Edge Technology™ to extend the life of the flighting. This provides an extra layer of steel welded to the edge on critical wear points. As a result, flighting lasts longer and needs to be replaced less often – saving time and money. To protect the finish and prevent rusting, Westfield uses a durable powder coat paint.

Smooth & Efficient Operation

The MKX2 Series uses square, one-bolt flight connections to ensure the flighting maintains proper alignment for smooth operation. The upper flight thrust adjuster equalizes the pressure between the upper and lower bearings during operation. This extends the life of the lower boot bearing. The CV PTO reduces vibration and provides maximum power transfer to the auger in order to maintain the life of the unit without sacrificing capacity. The large boot and tapered boot flight maximizes auger capacity at all angles by efficiently channeling grain from the hopper into the auger.

Easy To Service & Maintain

The removable slip-on boot flight uses Wear Edge Technology™ and can be quickly replaced without having to remove and replace the entire lower flight. The MKX2 Series features six easily accessible service points to allow for quick maintenance of u-joints, chains, bearings, and gearboxes. The u-joint end caps have external grease zerks, making it easy to service and maintain. Tool free inspection areas include, the hopper chain cover, neck transition, boot clean-out and swing head cover. The large clean-out, service points, and access panels allow for fast and efficient auger cleaning and servicing.

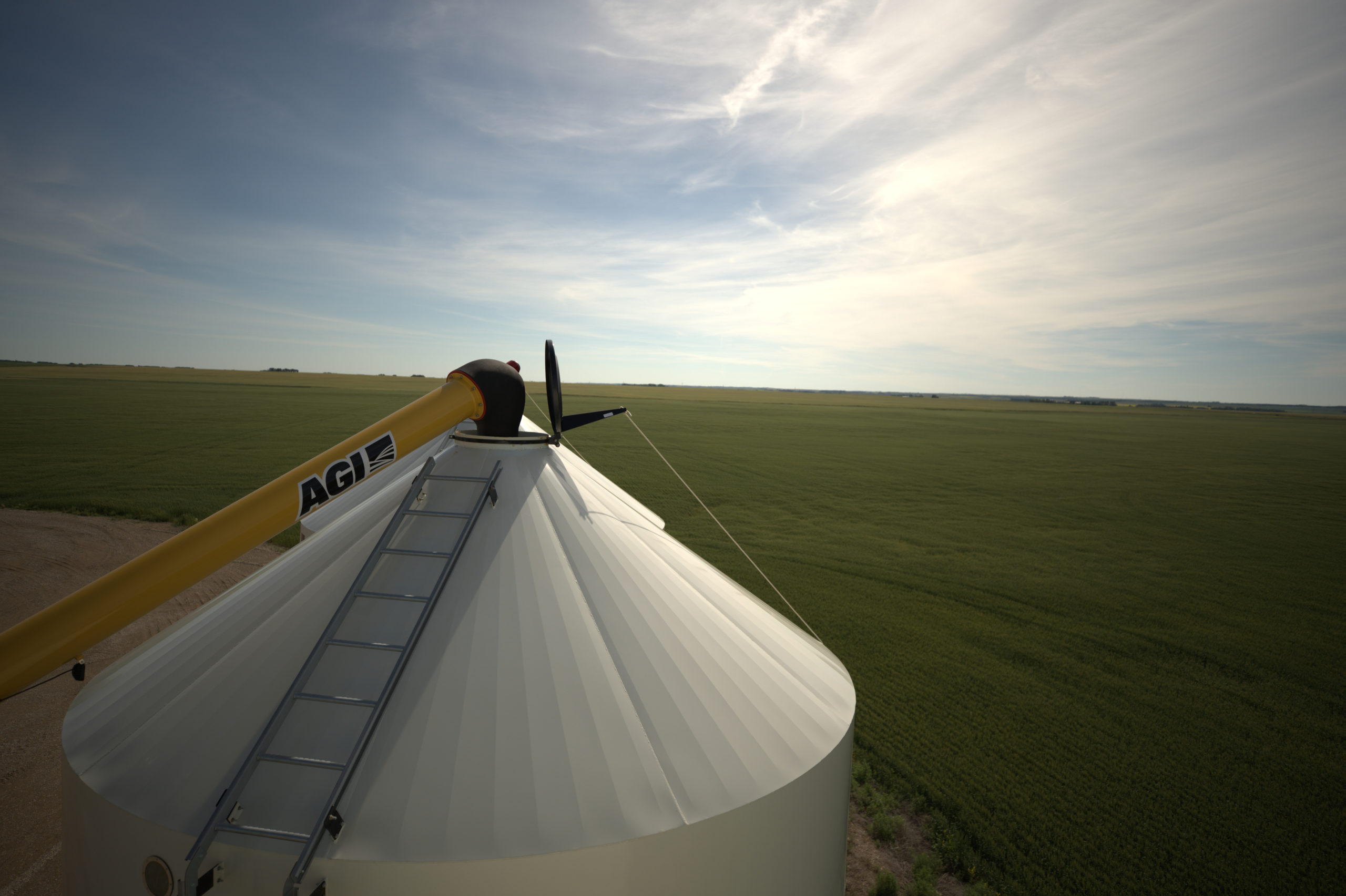

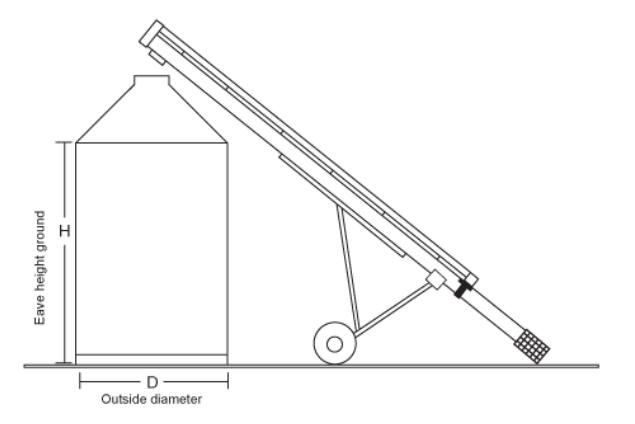

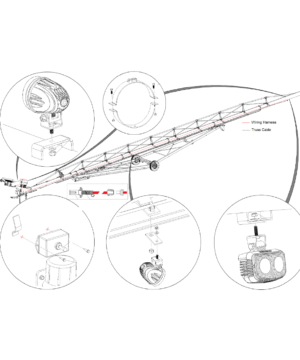

Trussing + Frame

The MKX2 Series is designed to maintain rigid alignment during heavy loads. Whether it’s heavy-duty cable trussing on smaller units or Westfield’s industry-leading steel trussing on longer, heavier units, the MKX2 withstands bowing to maintain proper tube and flighting alignment making it easier to line the auger up with the bin cap opening. The A-frame undercarriage is built to hold the auger in position and works with wide-standing axles to prevent the auger from swaying or moving once it has been positioned at the bin and the grain starts flowing.

Hopper + Hopper Lift Arm

The low profile hopper features left and right hand flighting to pull grain toward the center of the hopper so it flows efficiently up into the tapered boot – maximizing capacity and minimizing unload time. The 6″ rubber extension along the edge of the hopper prevents grain from splashing. The hopper lift arm and hopper can be positioned on the left or right hand side of the auger, offering the convenience of unloading from either side. Low Profile Hopper also has easy access drive components & u-joints with external grease zerks for maintenance.

| Weight | 9216 lbs |

|---|