Baumalight FEB700 88″ Stationary Flail Mower | Univ Skid | Flail Blades | 18-35 GPM | 4,000 PSI

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB BV ATWOOD, KS

*Case Drain Required

*Hoses Included – No Couplers (Add Couplers Below)

*Hose Extension Available For Skidsteers With Couplers On The Right Side Of The Boom – See Below

FEB700 Flail Mowers

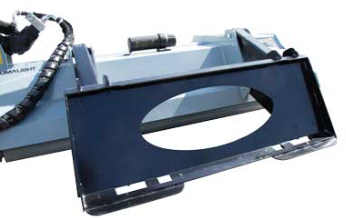

The Baumalight FEB700 flail mower is a heavy duty and versatile agricultural tool designed for efficiently mowing and mulching a variety of vegetation, including grass, weeds, light brush, and small trees. The mower features a sturdy frame that is designed to withstand the rigors of demanding work environments, making it ideal for use in agricultural, commercial, and municipal applications. Its low-profile design allows for excellent forward visibility and eliminates “blind spots” as material nears or enters the machine. With a path width of 88 inches and a rotor width of 80 inches, this flail mower is capable of covering large areas quickly and efficiently. The specially designed back discharge feature allows material to flow evenly and smoothly through the machine resulting in unmatched capacity and performance.

The rotor is equipped with heavy-duty, free-swinging flail knives that are designed to effectively cut and shred vegetation while minimizing damage to the underlying soil. The FEB700 Flail mower comes with 42 blade clusters in a spiral pattern, which are mounted on a rotor shaft that measures 1.75 inches in diameter. The rotor diameter at the tips is 17.5 inches, and the rotor weight, including tools, is 253 lbs.

The FEB700 uses a standard universal skidsteer mounting plate making it easy to attach and remove from your vehicle and works well from 18-35 GPM and takes up to 4000 PSI. However, it does require a case drain to be installed for smooth operation. To maintain a steady, even mow height, the flail mower can be easily adjusted by lifting or lowering the skidsteer plate as the mower pivots on the roller bar. The unique floating skidsteer plate and independent linkage provide free movement and allows the mower to glide over uneven surfaces ensuring a uniform and consistently mowed finish in most types of terrain.

To ensure the longevity of the FEB700 Flail mower and reduce repair costs over time, a built-in relief system is installed to provide protection against overload or other damaging events. This system protection plays a critical role in safeguarding the machine from potential damage. Overall, the Baumalight FEB700 flail mower is a heavy build light industrial tool with a goal to give reliable performance, durability, and versatility for a variety of mowing and mulching applications.

| Model # | FMM148 | FEB700 |

| Path Width | 61″ | 88″ |

| Rotor Width | 48″ | 80″ |

| Cutting Depth | Level | Level |

| Cutter style | Flail Blades | Flail Blades |

| No. of blade clusters | 38 | 42 |

| Rotor shaft size | 1.5 | 1.75 |

| Rotor diameter (tips) | 19″ | 17.5″ |

| Rotor weight (with tools) | 185 lbs | 253 lbs |

| Adaptor | Universal mini skidsteer | Standard skidsteer plate |

| Case drain required | Yes | Yes |

| System Protection | Built-in Relief system | Built-in Relief system |

| GPM | 8 – 15 | 18 – 35 |

| PSI | 2,000 – 4,000 | 4,000 |

| Unit Weight | 585 lbs | 1091 lbs |

FIXED ROLLER BAR

The fixed roller bar ensures that the flail mower cuts at a consistent height, which is important for maintaining a neat and tidy appearance, resulting in a more even cut across the entire area being mowed.

The fixed roller bar helps protect the flail mower’s blades from damage, as it prevents the blades from hitting rocks, stumps, or other obstacles on the ground.

CASE DRAIN – VENT TO ATMOSPHERE

To prevent pressure relief activation on the motor seal, the FEB700 comes with a case drain line and a vent to atmosphere relief valve. In the event there is a spike in pressure in your hydraulic lines, the case drain will relieve the pressure and drain it back into the return line and back to the tank. If the connection of the case drain (third line) is missed or if the line is blocked, then the case drain will vent to notify you. A properly installed case drain protected by a vent to atmosphere relief valve will save the work of replacing your shaft seal and save you from down time of unexpected maintenance.

What Is A Case Drain Line ?

On most skidsteer and excavator Hydraulic systems, Hydraulic motors and pumps require a case drain line. Sometimes referred to as a third line, the case drain line will relieve any excess pressure and drain it back to your return line, then into the reservoir. Without a properly installed case drain, that extra pressure could blow a seal or damage your hydraulic line. For higher flow motors or on piston and gear motors, a case drain line is always required. Although, no matter the size of your motor, a case drain is always a good idea as it will relieve the amount of pressure on your shaft seal, helping to prolong its life. A case drain line can also increase the efficiency of your hydraulic system as it will lower the back pressure on the tank line.

Since most machines have a unique style of coupler, BaumaLight does not include a coupler on our case drain line, although they are available. If your skidsteer is not equipped with a case drain, then it can be field installed.

How Important Is A Case Drain Line ?

If we say having a case drain is critical and you operate without one, you will blow out your shaft seal. Be sure to check the motor sizing charts on our website.

Exception If You Have A Hammer Valve

There is one exception in the need for a case drain on gear motors and that is if you excavator is equipped with a hammer valve, this is a larger free flow line back to tank.

Identifying Your Case Drain Line

The following galleries show a highlighted case drain line on multiple skidsteer and excavator models.

Unit Does Not Include Hyd Couplers – They Must Be Added To Complete Unit.

The Hose Size On The FEB700 Is ¾”

| Weight | 1091 lbs |

|---|

WLD004904

WLD004904  CMM6

CMM6  WLD001065

WLD001065