Baumalight MS1160 75″ Brush Mulcher | Univ. Skid | 7,000 lb Min Carrier | D117X2 Mtr 20-45 GPM

*PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB BV ATWOOD, KS

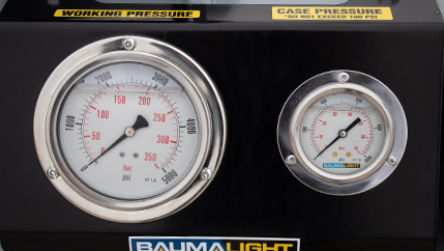

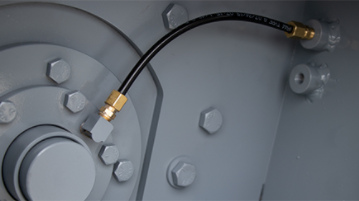

*Case Drain Required

*Hydraulic Hoses Included – No Couplers

*30 Minute Dealer Set-Up To Fine Tune Two Speed Motor

MS1160 Heavy Duty Fixed Tooth Mulcher for Skidsteer

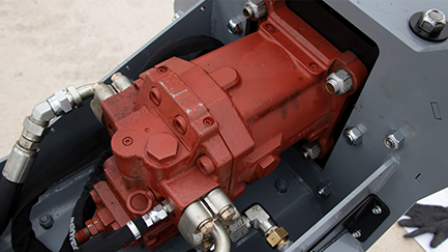

The Baumalight MS1160 Brush Mulcher has a 75” mulching path and is designed for skidsteers with a 7,000 lb minimum weight. The MS1160 comes with unique performance boosting mulcher rings (licensed by Denis Cimaf) and is powered by a bent axis piston motor. The MS1160 uses a fixed tooth holder and comes with 31 sharpenable planer teeth (P11000), as you will see in the brush cutting size charts this allow mulching of much larger material with an average skidsteer. Units may NOT be ordered from the factory with ripper teeth, but you can order ripper teeth and replace on your own. The MS1160 skidsteer mulcher also come with a large pressure gauges which is very handy to watch and see how close you are to maximum pressure; ensuring that you maintain an optimal flow.

| Model No. | MS248 | MS348 | MS548 | MS560 | MS572 | iSeries MS760 | iSeries MS772 | MS960 | MS972 | MS1160 |

|---|---|---|---|---|---|---|---|---|---|---|

| Path Width | 60″ | 60″ | 62″ | 75″ | 87″ | 75″ | 84″ | 75″ | 84″ | 75″ |

| Rotor Width | 48″ | 48″ | 48″ | 60″ | 72″ | 60″ | 72″ | 60″ | 72″ | 60″ |

| Minimum carrier weight | 2,000 | 3,000 | 4,000 | 5,500 | 6,000 | 8,000 | 8,500 | 7,000 | 7,500 | 7,000 |

| Cutting Depth | Level | Level | 1.5″ Above to 1″ Below Grade | 1.5″ Above to 1″ Below Grade | 1.5″ Above to 1″ Below Grade | Standard level – Optional skid shoes for below ground | Standard level – Optional skid shoes for below ground | Standard level – Optional skid shoes for below ground | Standard level – Optional skid shoes for below ground | Standard level – Optional skid shoes for below ground |

| Holder Style | Swing | Fixed | Fixed | Fixed | Fixed | Fixed | Fixed | Fixed | Fixed | Fixed |

| Tool Style | Flail | High Speed Teeth | Carbide Tipped Bolt In | Carbide Tipped Bolt In | Carbide Tipped Bolt In | Carbide Tapper Fit | Carbide Tapper Fit | Double Tipped | Double Tipped | Sharpenable Planer |

| Number of cutters | 30 | 60 | 104 | 126 | 160 | 78 | 94 | 38 | 43 | 31 |

| Rotor Diameter (tool tips) | 17.25″ | 15″ | 15″ | 15″ | 15″ | 17.25″ | 17.25″ | 18.5″ | 18.5″ | 19.3″ |

| Rotor Weight (with tools) | 125 lbs | 230 lbs | 480 lbs | 575 lbs | 700 lbs | 800 lbs | 930 lbs | 860 lbs | 1,105 lbs | 860 lbs |

| System Protection | Built-In Relief | Built-In Relief | Built-In Relief | Built-In Relief | Built-In Relief | Built-In Relief | Built-In Relief | Built-In Relief | Built-In Relief | Built-In Relief |

| Hydraulic Couplers | Included | Included | Check with Dealer | Check with Dealer | Check with Dealer | Not Included | Not Included | Not Included | Not Included | Not Included |

| Unit Shipping Weight | 750 lbs | 950 lbs | 1491 lbs | 2115 lbs | 2266 lbs | 2600 lbs | 3150 lbs | 2975 lbs | 3115 lbs | 2800 lbs |

CASE DRAIN – VENT TO ATMOSPHERE

To prevent pressure relief activation on the motor seal, the MS1160 comes with a case drain line and a vent to atmosphere relief valve. In the event there is a spike in pressure in your hydraulic lines, the case drain will relieve the pressure and drain it back into the return line and back to the tank. If the connection of the case drain (third line) is missed or if the line is blocked, then the case drain will vent to notify you. A properly installed case drain protected by a vent to atmosphere relief valve will save the work of replacing your shaft seal and save you from down time of unexpected maintenance.

WIRE PROTECTION KIT

If you are mulching and you catch some old fence wire, it can really cause damage to the unit if the wire slips over the edge of the rotor and gets wrapped around the shaft. The wire can get bunched against the bearings, causing major damage. Our wire protection kit contains a welded raised area on the end of the rotor that protects the shaft and prevents wire from getting in.

MAXIMUM BRUSH CUTTING SIZES (Brush Diameter in Inches)

900 Series

| MOTOR | PSI | CASE DRAIN | 20 GPM |

25 GPM |

30 GPM |

35 GPM |

40 GPM |

45 GPM |

50 GPM |

|---|---|---|---|---|---|---|---|---|---|

| RPM | 1450 | 1800 | 2100 | ||||||

| C930 Bent Axis Piston |

3000 3500 4000 |

Critical | 4″ 4.5″ 5.5″ |

5″ 5.5″ 6″ |

6″ 6.5″ 7″ |

— — — |

— — — |

— — — |

— — — |

| RPM | 1500 | 1800 | 2100 | ||||||

| C940 Bent Axis Piston |

3000 3500 4000 |

Critical | — — — |

4.75″ 5.25″ 5.75″ |

6.5″ 6.75″ 7″ |

7″ 7.5″ 8″ |

— — — |

— — — |

— — — |

| RPM | 1600 | 1875 | 2140 | ||||||

| C950 Bent Axis Piston |

3000 3500 4000 |

Critical | — — — |

— — — |

6″ 6.5″ 6.75″ |

7.5″ 8″ 8.5″ |

8″ 8.5″ 9″ |

— — — |

— — — |

| RPM | 1400 | 1630 | 1830 | 2030 | |||||

| C970 Bent Axis Piston |

3000 3500 4000 |

Critical | — — — |

— — — |

— — — |

6″ 7.5″ 8″ |

6.5″ 7″ 7.5″ |

8″ 8.5″ 9″ |

8.5″ 9″ 9.5″ |

Double brush size for “stop and chew” cutting for skidsteer models ONLY

NOTICE: Max GPM value must NEVER be exceeded on roller-vane motors or failure will occur, Piston motors run much faster before failure will occur

NOTICE: Above GPM values are under load flow estimates

1100 Series

| MOTOR | PSI | CASE DRAIN | 20 GPM |

25 GPM |

30 GPM |

35 GPM |

40 GPM |

45 GPM |

50 GPM |

55 GPM |

60 GPM |

65 GPM |

70 GPM |

75 GPM |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RPM | 1450 | 1800 | 2100 | |||||||||||

| C1130 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | 4.5″ 5″ 5.5″ 6.5″ |

5.5″ 6″ 6.5″ 7″ |

6.5″ 7″ 7.5″ 8″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1500 | 1800 | 2100 | |||||||||||

| C1140 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

6.25″ 6.75″ 7.25″ 7.75″ |

8.25″ 8.5″ 8.75″ 9″ |

8.5″ 9″ 9.5″ 10″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1600 | 1875 | 2140 | |||||||||||

| C1150 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

8.5″ 9″ 9.5″ 9.75″ |

10″ 10.5″ 11″ 11.5″ |

10.5″ 11″ 11.5″ 12″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1400 | 1630 | 1830 | 2030 | ||||||||||

| C1170 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

9.5″ 10″ 11.5″ 12″ |

10″ 10.5″ 11″ 11.5″ |

11.5″ 12″ 12.5″ 13″ |

12″ 12.5″ 13″ 13.5″ |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

| RPM | 1400 | 1570 | 1750 | 1900 | ||||||||||

| C1190 Bent Axis Piston |

2500 3000 3500 4000 |

Critical | — — — — |

— — — — |

— — — — |

— — — — |

— — — — |

10″ 10.5″ 11″ 11.5″ |

12.5″ 13″ 13.5″ 14.5″ |

14″ 14.5″ 15″ 15.5″ |

14.5″ 15″ 15.5″ 16.5″ |

— — — — |

— — — — |

— — — — |

| RPM | Adjustable | |||||||||||||

| D117X2 Two speedBent Axis Piston |

2500 3000 3500 4000 |

Critical | 5.5″ 6.25″ 6.75″ 8″ |

7.75″ 8.25″ 9″ 9.5″ |

10.5″ 11.25″ 11.5″ 12″ |

12.5″ 13″ 13.5″ 14.25″ |

13″ 13.75″ 14.25″ 15″ |

14.25″ 15″ 15.5″ 16.25″ |

15.5″ 16.25″ 16.75″ 18″ |

17.5″ 18″ 18.75″ 19.25″ |

18″ 18.75″ 19.25″ 20.5″ |

19″ 19.75″ 20.25″ 21.5″ |

20″ 20.75″ 21.25″ 22.5″ |

21″ 21.75″ 22.25″ 23.5″ |

Double brush size for “stop and chew” cutting for skid steer models ONLY

NOTICE: Max GPM value must NEVER be exceeded on roller-vane motors or failure will occur, Piston motors run much faster before failure will occur

NOTICE: Above GPM values are under load flow estimates

Unit Does Not Include Hyd Couplers – They Must Be Added To Complete Unit.

The Hose Size Is ¾” & The Ends Are ¾” JIC

The MS1160 Comes With P11000 Planer Teeth.

Units May NOT Be Ordered From The Factory With Ripper Teeth, But You Can Order Ripper Teeth And Replace On Your Own.

Planer Tooth Style

The Planer style tooth feeds its appetite for brush bit by bit, taking small bites and providing the most efficient mulching and cutting. Although planer style teeth are efficient, their flat profile make them vulnerable to shattering on impact with rocks and other debris. For that reason, this style of tooth is recommended for cutting applications where efficiency is more important than tooth life. Planer teeth are bolt-on replaceable for quick and easy servicing and replacement even in the field.

Ripper Tooth Style

Ripper style teeth is a general use tooth, offering operators a shredding mulching action. Their v-shaped design makes them less susceptible to impacts with hard objects like stones, making them the better choice when mulching below grade and in fence lines. Ripper teeth are bolt-on replaceable for quick and easy servicing and replacement even in the field.

| Weight | 2860 lbs |

|---|