S24 Stump Grinder | Univ Skid | S545 Motor | 30-80 HP | 22-32 GPM | Swing Cyl

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB BV ATWOOD, KS

*Requires Case Drain (See Tab Below For Info On Case Drains)

*Hydraulic Hoses Included – NO Couplers (See Tab Below To Add Hyd Couplers)

*The Unit Comes With Baumalight’s Auxiliary Electrical Connection. When Ordering Unit, Please Note What Model Of Skid Steer It Is Going On & The Pin Connection. Baumalight Will Equip The Unit With Your Skid Steer’s Specific Auxiliary Connection Prior To Shipment.

- A Control Box Kit Must Be Added If –

- Your Skid Steer Is Older And Does Not Have An Auxiliary Electrical Connection

*Do You Have A Newer Bobcat Skid Steer With A Specific Bobcat 7-Pin Connector?

- To Run This Unit With Your Skid Steer, You Will Either Have To Add The Control Box Kit, Add The Bobcat 7-Pin CANBUS Plug/Circuit Board Kit, Or Contact Your Bobcat Dealer For A 7-Pin To 14-Pin Adapter.

S24 Stump Grinder

The S24 skid steer stump grinder features a specially designed 12V diverter valve to allow control of the hydraulic swing cylinder, for a more refined cutting pass. Combined with our flow control this remote will give you precise control of the cutting pass and allow you to grind more of the stump without repositioning. Cutting depth is up to 15″ below ground with a swing radius of 80 degrees. The floating deflector safely directs the flow of debris for quick clean up. The S24 is a good choice for skidsteer stump grinding on close cut grass such as golf courses as well as for stump grinder rental on medium sized skidsteers and track loaders.

For best stump grinding performance we offer multiple motor options to exactly match the hydraulic flow of your skidsteer as well as 8 pin and 14 pin AUX electrical plugs as well as the 7 pin Bobcat so you can use the controls in your cab with no extra wiring or hand controls.

| Model No. | S14 | S18 | S24 | S28 | S40 |

|---|---|---|---|---|---|

| Recommended HP Size | 12-30 | 25-80 | 30-80 | 50-120 | 50-120 |

| Maximum Carrier Size | Check GPM & PSI | Check GPM & PSI | Check GPM & PSI | Check GPM & PSI | Check GPM & PSI |

| Motor Type | Gerotor | Gerotor | Gerotor | Gerotor | Bent Axis Piston |

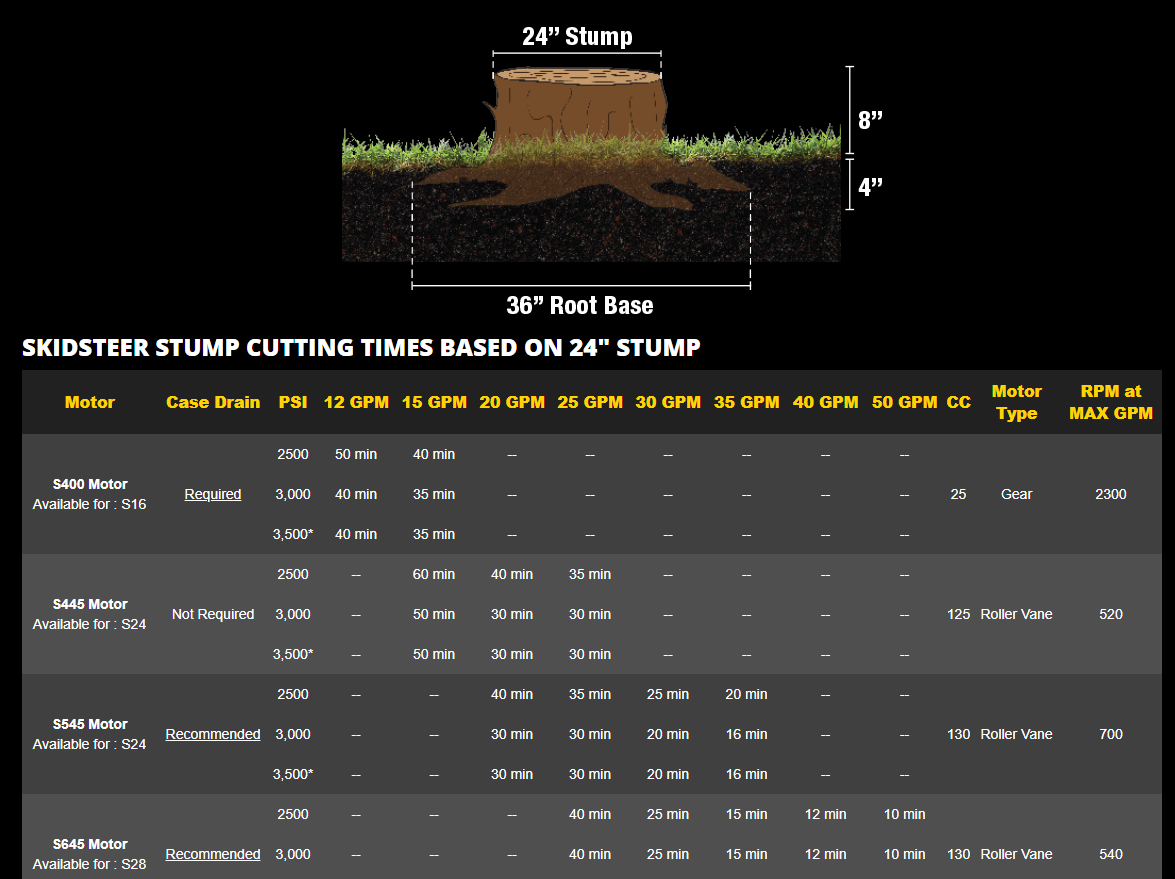

| Hydraulic GPM | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart |

| Rotor Size | 18″ | 24″ | 24″ | 24″ | 24″ |

| Number of Teeth | 12 | 34 | 34 | 34 | 20 |

| Tooth Construction | Wearsharp® | Planer | Planer | Planer | Wearsharp® |

| Cutting Wheel Speed | Depends on GPM | Depends on GPM | Depends on GPM | Depends on GPM | Depends on GPM |

| Cutting Height – Above Ground | No limit | No limit | No limit | No limit | No limit |

| Cutting Depth – Below Ground | 6″ | 10″ | 10″ | 10″ | 24″ |

| Maximum Cutting Depth – Per Pass | 2″ | 5″ | 6″ | 6″ | 1″ |

| Maximum Horizontal Cut | 12″ | 22″ | 22″ | 22″ | 22″ |

| Swing Arc | Self-feeding | Self-feeding | 80° | 80° | 85° |

| Hub Torque | 150 Ft.-Lbs. | 250 Ft.-Lbs. | 250 Ft.-Lbs. | 803 Ft.-Lbs. | – |

| Over Torque Protection | Relieve valve | Relieve valve | Relieve valve | Relieve valve | Remote |

| Hitch | 1″ pivot pins | 1″ pivot pins | Quick Attach | Quick Attach | Quick Attach |

| No. of Remotes Required – Hydraulic | 1 | 1 | 1 | 1 | 1 |

| Requires 12 Volt DC | No | No | Yes | Yes | Yes |

| Unit Weight (Shipping) Lbs. | 394 | 642 | 995 | 995 | 1,200 |

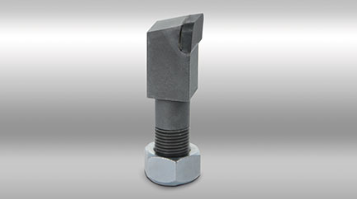

CARBIDE TIPPED

Like the finest saw blades, the cutting teeth on Stump Blasters are carbide tipped. This incredibly hard material ensures reliable cutting performance. When grinding stumps, buried hazards are inevitable; gravel, stones even metal posts are not uncommon to “find”. Our carbide teeth are designed to stand up to this abuse and keep on blasting stumps to dust.

6 FREE TEETH

All S24 Stump Grinder comes with a free set of 6 replacement teeth. These replacement teeth are conveniently shipped in a robust enclosed compartment on top of the frame.

MORE TEETH

The high number of teeth means that each tooth needs to do less work. Each of the Stump Blasters teeth only need to make a small cut, because the work is shared by more of our rugged teeth they last longer and usually only require 2 or 3 replacements at a time. The bolt-on designed teeth allow for straightforward replacement.

ROTOR

The massive ¾” thick steel rotor provides the back bone for the Stump Blaster cutting system. It’s the anchor for the carbide tipped teeth. For smooth operation it’s important that the rotor remains solid, with no flexing. The rugged rotor also provides the Stump Blaster with the extra momentum needed when the grinding is tough, making sure the Stump Blaster can power through the hardest stumps.

FLOW CONTROL

Fine tune the performance of your Stump Blaster easily with the Flow Control knob. The Flow Control allows you to adjust the cutting pass speed, to match the size and performance of your tractor. This gives you the smoothest cut possible and with the full return back to the start position, the quickest overall stump grinding time possible.

HYDRAULIC MOTOR

Skid steer mounted Stump Blasters run on hydraulic motors. For best results, match your equipments flow rate to one of our available hydraulic motor options.

MORE CLEARANCE

The Stump Blaster’s carbide teeth extend a full 1-¼ inches from the rotor. This prevents chips and mulch from getting plugged. More chip clearing produces smoother operation and reduces heat build-up that can damage the rotor and cause premature tooth failure.

FLOATING DEFLECTOR

The deflector floats as you grind providing chip and debris control from first cut to maximum depth without getting in the way. In tight grinding situations the deflector can be flipped up out of the way.

HARDENED STEEL BUSHING

Spring Bushings made from high grade chrome-vanadium AISI 6150 spring steel on all main pivot points.

GREASEABLE PINS

Our grease pins are zinc plated to prevent corrosion which will allow for smoother operation of the units joints over their lifetime.

What Is A Case Drain Line ?

On most skidsteer and excavator Hydraulic systems, Hydraulic motors and pumps require a case drain line. Sometimes referred to as a third line, the case drain line will relieve any excess pressure and drain it back to your return line, then into the reservoir. Without a properly installed case drain, that extra pressure could blow a seal or damage your hydraulic line. For higher flow motors or on piston and gear motors, a case drain line is always required. Although, no matter the size of your motor, a case drain is always a good idea as it will relieve the amount of pressure on your shaft seal, helping to prolong its life. A case drain line can also increase the efficiency of your hydraulic system as it will lower the back pressure on the tank line.

Since most machines have a unique style of coupler, BaumaLight does not include a coupler on our case drain line, although they are available. If your skidsteer is not equipped with a case drain, then it can be field installed.

How Important Is A Case Drain Line ?

If we say having a case drain is critical and you operate without one, you will blow out your shaft seal. Be sure to check the motor sizing charts on our website.

Exception If You Have A Hammer Valve

There is one exception in the need for a case drain on gear motors and that is if you excavator is equipped with a hammer valve, this is a larger free flow line back to tank.

Identifying Your Case Drain Line

The following galleries show a highlighted case drain line on multiple skidsteer and excavator models.

Controls Overview

Auxiliary Connection (Included Standard)

*If you have a newer skid steer with auxiliary connection, please note what model of skid steer it is going on & the pin connection. Baumalight will equip the unit with your skid steer’s specific auxiliary connection prior to shipment. This Is The Ideal Solution. The operator can easily control all functions using the controls already equipped on the carrier joysticks. This allows the operator to never remove their hands from the controls to change a function.

Wired Control Box (Optional)

*If your skid steer is older & does not have an auxiliary electrical connection, you must add the wired control box. Although less than ideal, for controlling the attachment is using our wired control box. The operator would use the toggle switches on the control box to control the functions required. The wired control box requires a 12V connection to supply power.

Do You Have A Newer Bobcat Skid Steer With A Specific Bobcat 7-Pin Connector?

-If so, you will either have to add the control box kit, the Bobcat 7-pin CANBUS plug/circuit board kit, or contact your Bobcat dealer for a 7-pin to 14-pin adapter.

| Weight | 860 lbs |

|---|