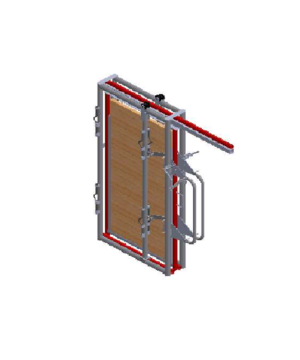

Chaparral High Pole Gate | 8′ W x 6′ H – 9’6″ Overhead Frame | 1.9″ 16 Ga Tubing

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

- High Pole Gates

- Panels

- Panel Gates

- Gates-In-Frame

- Alley Control Gates / Frames

- Palpation Cages

- Block Doors

- Panel Mounting Brackets

- Wall Mount Brackets

- Alley Stops

- Panel Post Pad Anchors

- Terrian Adjustment Brackets

- Horseback Gate Latches

- Triple Socket Pin-Pin Adapters

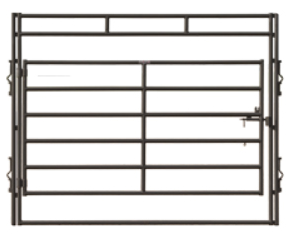

Chaparral High Pole Gates

Constructed from 1.9″ 16-gauge high tensile steel tubing, the Chaparral high pole gate provides the same outstanding features as the Classic series. Hinged on tough 3″ no-sag hinge collars, each gate comes equipped with a positive spring activated latch to guarantee years of dependable service.

- 1.9 high tensile 16 gauge tubing with 50,000 P.S.I. yield strength

- A variety of panel and gate heights to customize your handling system

- Self-contained male connecting pins

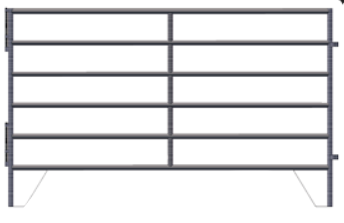

Standard Chaparral Panels

The Chaparral panels are available in several lengths. These units feature a self-contained connecting pins for easy interlocking with other Chaparral components. All panels have saddle cut vertical spacers for that added extra strength. All WW panel and gate joints are saddle cut for extra strength.

- 1.9 high tensile 16 gauge tubing with 50,000 P.S.I. yield strength

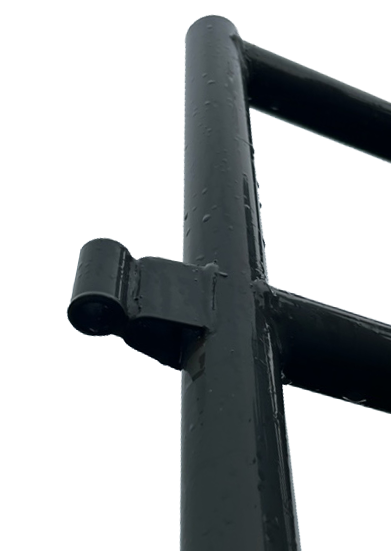

- All components feature self-contained connecting pins for easy interlocking

- 1 side is has self-contained male connecting pins & the other side has 3-way female spaces for easy interlocking

J-Leg Chaparral Panels

The Chaparral panels are available in several lengths. These units feature a self-contained connecting pins for easy interlocking with other Chaparral components. All panels have saddle cut vertical spacers for that added extra strength. All WW panel and gate joints are saddle cut for extra strength. J-Leg panels are easier for one person to drag around. These panels typically do not sink into the ground as much. The only downfall these panels may have is if a horse would fall, they may catch their leg in the J-Leg loop.

- 1.9 high tensile 16 gauge tubing with 50,000 P.S.I. yield strength

- All components feature self-contained connecting pins for easy interlocking

- 1 side is has self-contained male connecting pins & the other side has 3-way female spaces for easy interlocking

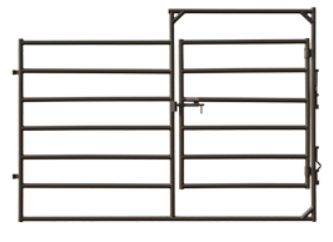

Chaparral Panel Gates

The Chaparral gate panel is engineered to fill that panel length opening while still offering the convenience of a 48″ walk through gate… This sturdy unit is available in 8′, 10′ or 12′ lengths. Spring-activated gate latches and 2″ standard pipe hinges give WW gates trouble-free service. All WW panel and gate joints are saddle cut for extra strength. Choose a long lasting, attractive, powder coat finish pre-galvanized or hot dipped galvanized.

- 1.9 high tensile 16 gauge tubing with 50,000 P.S.I. yield strength

- A variety of panel and gate heights to customize your handling system

- 1 side has self-contained male connecting pins & 1 side has 1-way female spaces for easy interlocking

Chaparral Gates-In-Frame

With the same quality latches and hinges as the Chaparral high pole gates, this convenient walk through gate is available in several sizes to meet your individual requirements. Spring-activated gate latches and 2″ standard pipe hinges give WW gates trouble-free service. All WW panel and gate joints are saddle cut for extra strength. Choose a long lasting, attractive, powder coat finish pre-galvanized or hot dipped galvanized.

- 1.9 high tensile 16 gauge tubing with 50,000 P.S.I. yield strength

- A variety of panel and gate heights to customize your handling system

- 1 side is has self-contained male connecting pins & the other side has 1-way female spaces for easy interlocking

WW Chaparral Alley Control Gates / Frames

- Create a single file alley of any length by attaching Chaparral panels to Chaparral 28″ alley control gates and frames.

- Alley Control Gates / Frames are Measured center to center of frame uprights. Actual opening is 26″.

- 1.9 high tensile 16 gauge tubing with 50,000 P.S.I. yield strength

- Spring-activated gate latches and 2″ standard pipe hinges give WW gates trouble-free service

- Both sides @ each connection point have 2 self-contained male connecting pins & 1 female

Why We Use Alley Control Gates / Frames

Cattle alley gates are an integral part of your cattle handling system. They create the stop gate strategy that allows stockmen and women to safely and efficiently work cattle through the system. Alley gates are essential in regulating cattle flow through your handling system.

Placement of cattle alley gates is dependent on the type of cattle handling system, location, and uses. Curved and straight configured alleys have different set points for the alley gates. The number of cattle being worked in a system is another determining factor for where stop gates may be necessary.

Cattle flow, or the lack thereof, is the goal of stop gate strategy. Placement of alley gates in your cattle handling system is all about regulating flow. It is important to only place the gates where you need them; too many gates can negatively disrupt cattle flow and create balking issues.

Alley gates prevent extra animals from entering the chute, can keep cattle from moving backwards, and ensure that the cattle handling system does not become overcrowded.

Placing Your Alley Control Gates / Frames

Alley gates should make your handling system safer and more efficient. Using rolling cattle alley gates will allow you to move them as needed in your system, depending on the size of cattle, or number of head being worked. This adaptability adds longevity to your system, as it can grow and change with your operation.

Use the following guidelines to place your alley gates:

- The rule of thumb is to have one alley gate at the entrance from the cattle tub, and one before the squeeze chute as a stop gate preventing extra animals from entering. Additional alley gates are placed in larger systems. In a small system, these two may be enough.

- Longer cattle handling systems require more alley gates than shorter systems. In a longer system, use alley gates to separate cattle into smaller groups, or ease the flow into the chute.

- You may need to add alley gates in places where the cattle handling system branches off. Examples include before a loading ramp, at the calf table, or ahead of sorting pens.

There is no golden rule for the number of alley gates to add to a cattle handling system, or where they should be placed. As a stockman or woman, you know your preferences for working cattle, and should place gates in locations that will increase efficiency and safety on your operation. Strategically placed alley gates will simplify and streamline the cattle handling process.

Cattle handling system design, handler technique, and cattle behavior are intertwined in the success or failure of cattle handling on your operation. When all factors are in check, the right corral and cattle handling system design can ease stress for cattle, and make the handlers’ job easier.

Palpation Cages

- 1-1/2″ Schedule 40 Pipe

- Palpation Cages have single female connection points @ 2 locations on both sides.

Rolling Block Doors

- 2-1/4″ 13 Ga Tubing

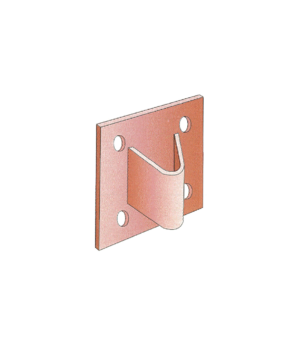

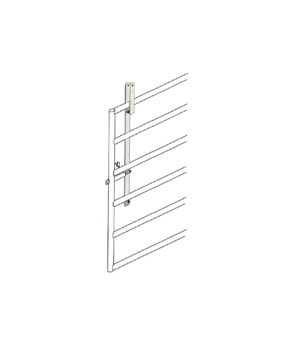

Panel Mounting Brackets

U-Bolt Panel Mounting Brackets To Any Panel To Add Additional Panels To Your Operation.

If You Want To Angle Panels Left Or Right, Be Sure To Get The LH Or RH Panel Depending On Your Plans.

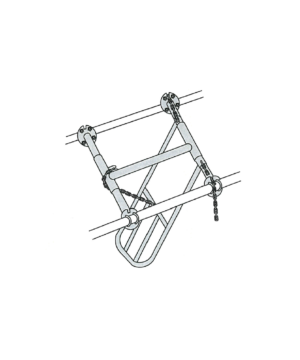

Terrian Adjustment Brackets

Use This Wedge To Put A Panel On Uneven Ground.

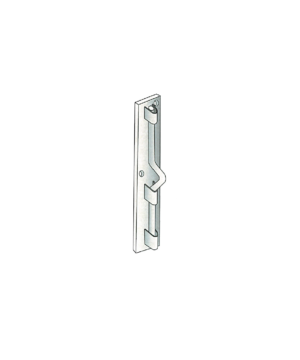

Horseback Gate Latches

Designed for ease of opening from horseback, the horseback latch handle is fabricated from 1-3/4” x ¼” Strap, 43-1/2” long. Handle has pre-punched holes designed to receive rope. Handle is attached to plunger latch which consists of 1” round bar plunger bolt with ½” threaded stem housed in 1” standard pipe, 8” long. Recoil action is provided by a compression spring on the threaded stem between the latch bolt and back of housing.

Triple Socket Pin To Pin Adapters

Connect Two Male To Male End Panels Or Gates With The Triple Socket Adapters