Danuser Mini MAC Bucket Concrete/Asphalt/Grain Mixer | Mini Skid | Steel/Rubber Auger | 1/4 Yard Cap

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

Danuser Mini Mac

We’re excited to introduce the Danuser Mini MAC—a compact mixing & conveying bucket engineered for mini track/mini skid loaders. It replaces manual mixing and awkward wheelbarrow runs with fast, precise dispensing—ideal for tight work zones like backyards, basements, between buildings, and underground sites.

COMPACT SIZE | BIG RESULTS

REPLACE MANUAL MATERIAL MIXING IN TIGHT SPACES!

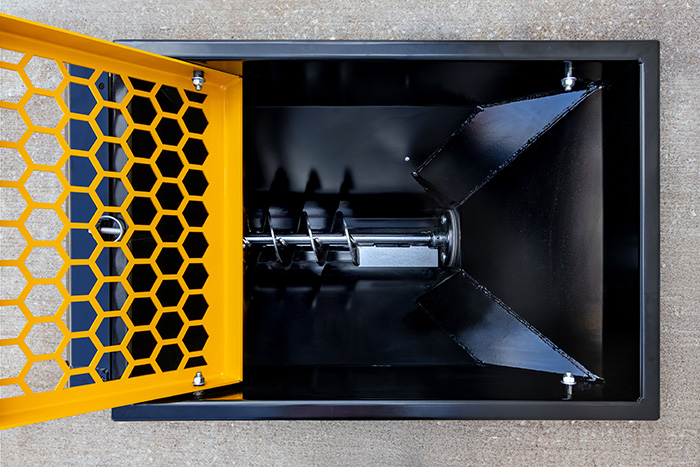

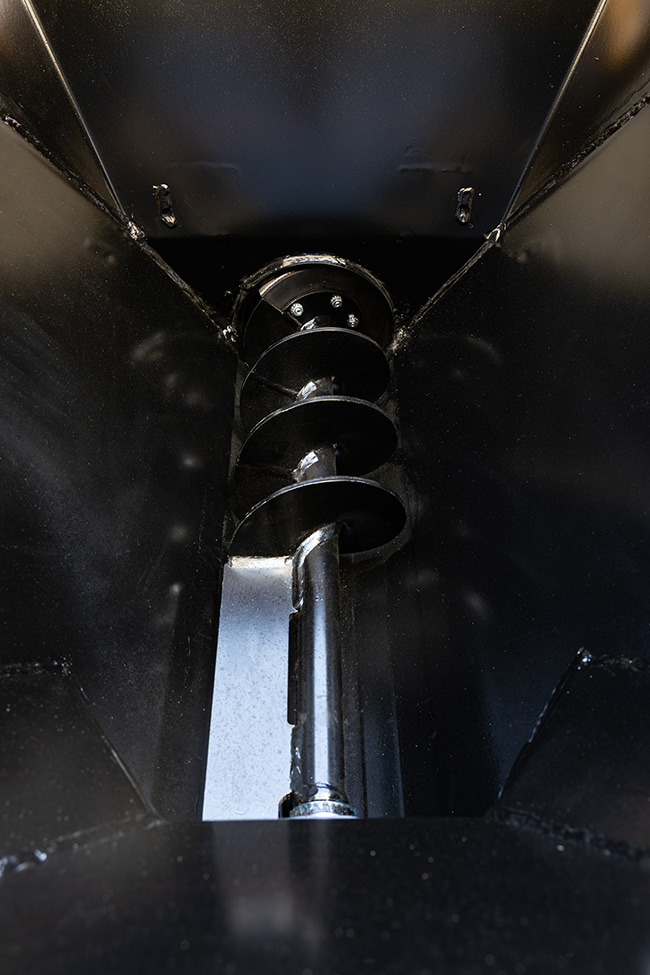

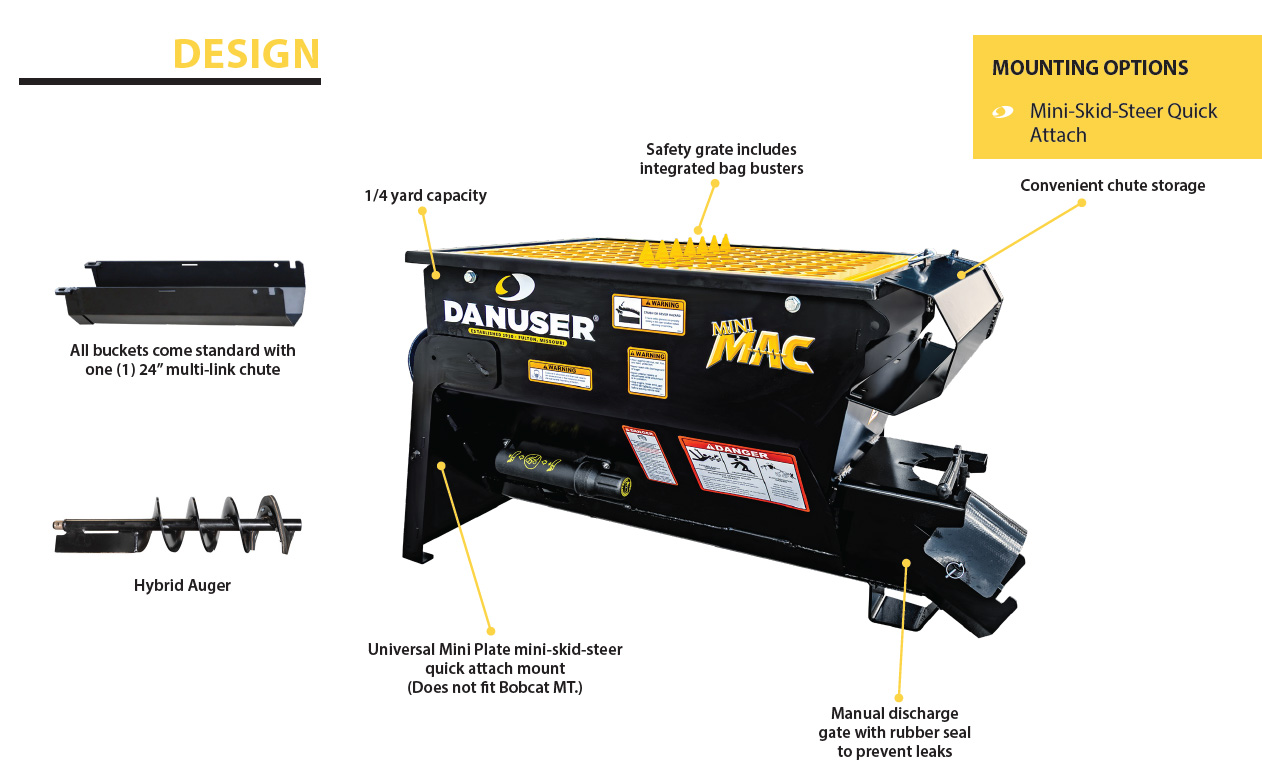

With a 1/4 yard capacity (6.75 cubic ft.), the Mini MAC is engineered for powerful mixing and precise dispensing in tight spaces like backyards, basements, between buildings, and underground sites. Built for mini track/skid loaders, this compact mixing and conveying (MAC) bucket features a mini-skid-steer quick attach mount on one end and a manual discharge gate on the other—delivering maximum functionality in a minimal footprint. The Mini MAC handles a wide range of materials including concrete (up to 1” slump), sand, wildlife feed, and agricultural grains. Its hybrid auger—made of steel and rubber—ensures efficient mixing while minimizing material seepage. Rubber sealing on the manual gate keeps materials contained throughout operation. For easy loading of bagged materials, the integrated safety grate features built-in bag busters. Each Mini MAC bucket comes standard with one (1) 24” multi-linked chute and two (2) hoses with flush-faced couplers (ISO 16028).

- Compact footprint, front discharge for access in tight spaces where larger mixers can’t reach.

- 1/4 yard (6.75 cu ft) capacity with hybrid auger for efficient mixing and minimal seepage.

- Handles concrete (up to 1″ slump), sand, wildlife feed, and agricultural grains.

- Comes standard with one (1) 24″ linked chute and two hoses with ISO 16028 flush face couplers.

- Safety grate with integrated bag busters speeds loading of bagged materials.

- Hydraulic requirements: up to 24 GPM, up to 3,500 PSI; dispense ~14 seconds @ 24 GPM (for a 1/4 yard load).

- Mounting: Universal mini skid steer quick attach (does not fit Bobcat MT).

- Weight: 370 lb.

- Warranty: 1 year

Mini Mac Advantages

- Front discharge allows for access to tight spaces

- Designed to fit anywhere your vehicle can

- 1/4 yard capacity (Approximately 9 bags of 80 lb. bag concrete mix)

- Works with a wide variety of materials including concrete (up to 1” slump), sand, wildlife grains, and agricultural grains

- Includes one (1) 24” multi-linked chute and hoses with flat faced ISO couplers

- Mini-skid-steer quick attach mount on one end and manual discharge gate on the other end for minimal footprint

- Comes standard with a safety grate with integrated bag busters.

For Mixing Materials

- With Mini MAC stationary, close the gate on the discharge end. Add dry material(s) to the discharge end of the bucket and the water to the motor end. Use the safety grate to break open bags by tossing the bag on the spikes and rocking the bag back and forth until it splits, dumping the material into the bucket.

- Run the auger in reverse. This will draw the dry material(s) into the liquid and up to the motor end of the bucket. Close the discharge gate to allow mixing in both directions.

- Continue to add more dry material(s) and liquid to get the volume and mixture that you require.

- When mixing is complete, stop the auger and position the vehicle so the discharge chute is directly over the desired discharge location. Attach any additional chute(s) required to safely reach the pouring location.

- Open the discharge gate by rotating the discharge gate handle. The gate lock mechanism will hold the gate open during operation.

- Run the auger in the forward direction to dispense the material(s).

Tips

- If dispensing and the auger locks up, material may be lodged between the auger and the side of the hopper. Run the auger in the opposite direction to attempt to remove the bind.

- Load dry materials at the discharge end.

Quick Q & A

- Can the Mini MAC be used to scoop the gravel and sand for mixing concrete?

- No: The dry material must be loaded into the discharge end and the water must be loaded into the motor end. (See page 6 for more information)

- What type of routine maintenance is required?

- Along with keeping the Mini MAC clean, the only routine maintenance required is to grease one zerk above the motor on the outside.

| Height, Grates Lowered | 30” |

| Height, Grates Raised | 48 5” |

| Overall Width | 24 5” |

| Overall Length | 54” |

| Overall Hopper Length | 38 7” |

| Weight | 370 lb |

| Auger Diameter | 6 12” |

| Center Column Diameter | 1 32” O D 0 18” wall |

| Auger Length | 27 5” |

| Flighting Spacing | 4” |

| Capacity | 1/4 yard (6 75 cu ft ) |

| 80-lb Bags Concrete Mix | Approx 9 (1/4 yard) |

| Dispense Rate | 14 seconds @ 24 GPM |

| Hydraulic Requirements | Up to 24 GPM Up to 3,500 PSI |

| Mounting Options | Mini-Skid-Steer Quick Attach |

| Materials |

| Concrete

(up to 1” slump) |

| Sand |

| Wildlife Grains |

| Agricultural Grains |

| Weight | 370 lbs |

|---|

DA11019

DA11019