WCX 1590S Straight Conveyor | Hyd Scissor Lift | S- Drive | 15″ Belt | 90′ Length | Up To 6,000 BPH

*Shipped Complete With

- Conveyor

- Hydraulic Scissor Lift Undercarriage

- Weather Guards

*Call For B.F.

*Must Add A Drive Kit To Complete Unit

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

Westfield Belt Conveyors

AGI Westfield Belt Conveyors are built tough to perform, yet designed and engineered for gentle handling of delicate seeds and commodities.

Gentle Handling

Specialty crops, seed and some commodities are very susceptible to impact damage caused by conventional grain handling systems. AGI Westfield Belt Conveyors minimize impact damage and help protect grade quality and germination performance of seed.

Low Maintenance / Long Wear

Engineered, designed and built for rugged, long-lasting performance with heavy-duty features like our quality rubber belting, rated up to 3,000 hours.

High Capacity

All AGI Westfield Conveyors are designed and built for high capacity and performance. Capacity increases as the angle of elevation decreases. See specifications for model performance.

Low HP

AGI Westfield’s unique design requires half the horsepower of screw augers, saving energy and freeing up larger tractors for other purposes.

Clean Convenience

AGI Westfield Belt Conveyors require very little clean-out when changing from one commodity to another; saving growers time and reducing contamination.

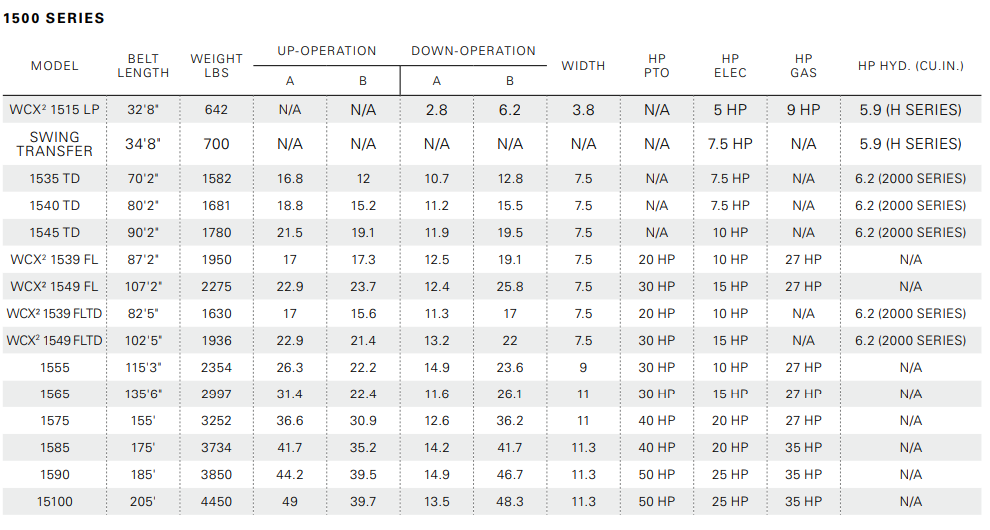

WCX1500 Scissor Lift Belt Conveyor Series

• Weather Guards

• Maximum Service height at 30-Degrees

• All belts are made of 2-ply Chevron, with nylon slider back

• Plastic hood and collapsible canvas hoppers provides excellent cushioning for fragile materials

• Capacity rated up to 6,000 bu/hr

• 10″ diameter, 14-gauge tube Note: 12-gauge tube for the first 30′

• Cable trussing

• Expandable axles

• S-Drive belt tensioner

• Scissor lift undercarriage

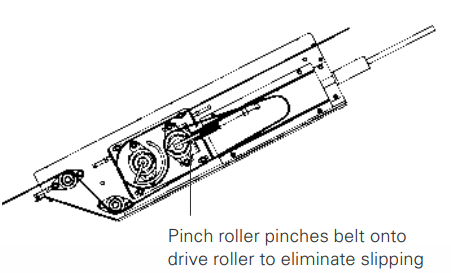

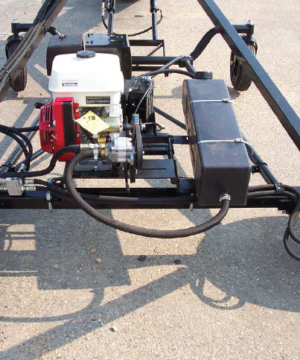

Pinch S Drive

AGI Westfield’s unique Pinch S-Drive is available on all S-Drive models and eliminates slippage by making it easy to set and maintain belt traction. The spring take up helps to maintain tension while less friction minimizes damage to the conveyor belt, also invoking minimal stress on the bearings. Gas, electric or PTO Pinch S-Drive options available.

Electric Drive Kit (Must Add)

Electric Motor (Must Add)

Pulley & Bushing (Must Add Both)

Gas Drive Kit (Must Add)

Gas Motor (Must Add)

Exhaust Kit (Must Add)

Wiring Kit (Must Add With 40 HP Motor)

Motor Install Kit (Must Add)

Battery Kit (Must Add)

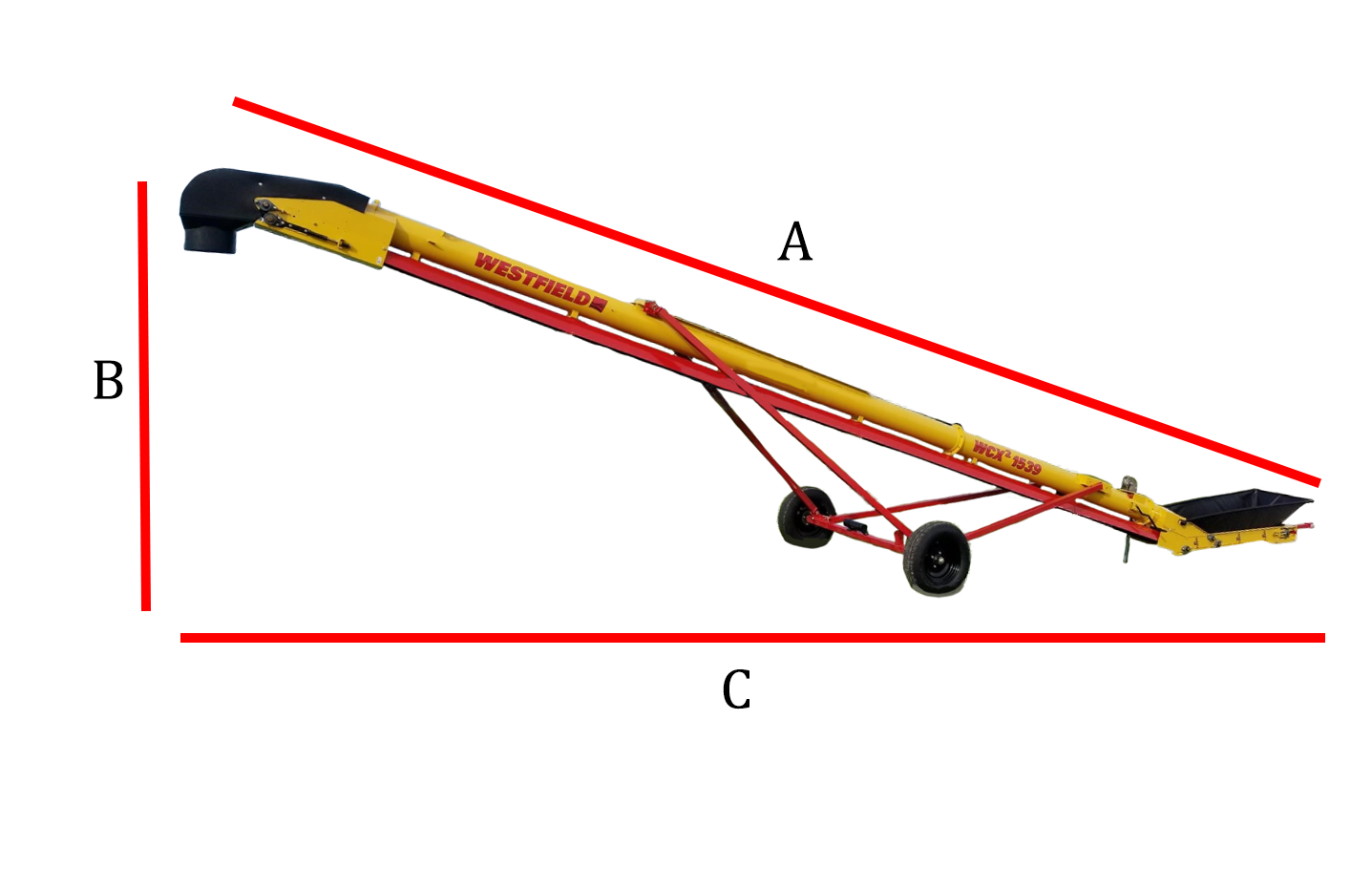

Westfield Conveyor Calculator

Find a conveyor that best fits your grain handling needs. Use the Westfield Calculator to help you determine:

- What length of conveyor will best complement you bin height

- How much ground length is necessary to ensure your conveyor will reach the desired bin height

The Westfield Calculator is easy to use and is designed to be practical. Use the Westfield Calculator as a tool to help you with your next conveyor purchase!

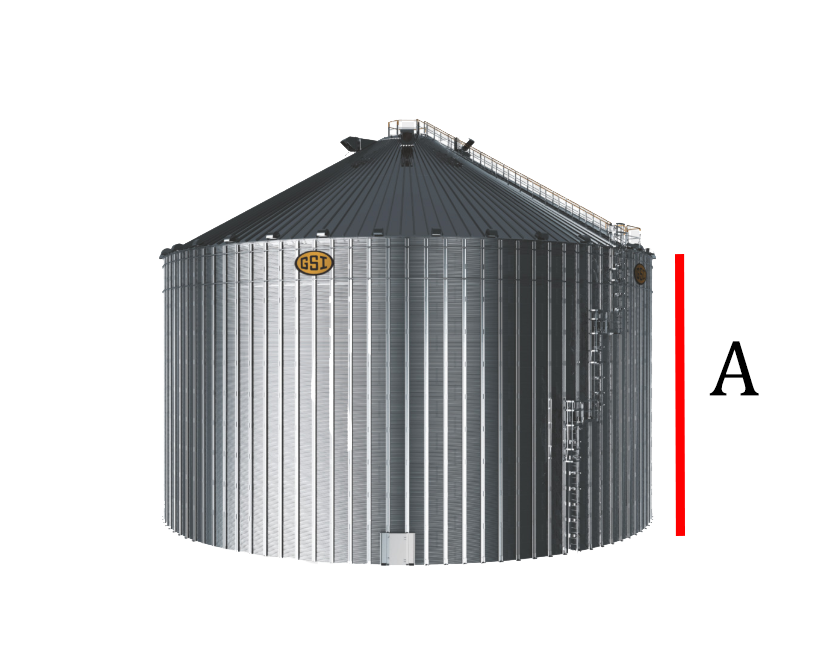

Conveyor Length

Do I need a 91 foot conveyor, or will a 31 foot conveyor do? Find out what conveyor length is the right choice for you bin’s peak height by using the Westfield Conveyor Length Calculator.

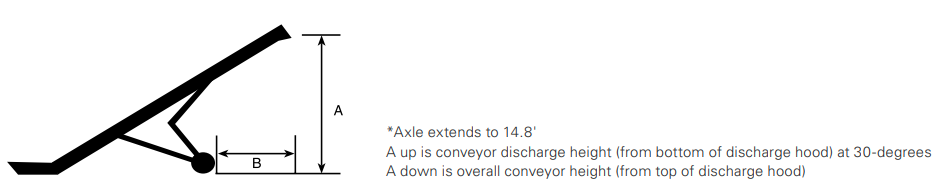

- Determine distance (A) from ground to eave of bin.

- Multiply the distance (A) by 2.5 to figure the minimum conveyor length needed.

Example: Bin height of 30’ X 2.5= 75’ – 75’ would be minimum length of conveyor you would want to look at.

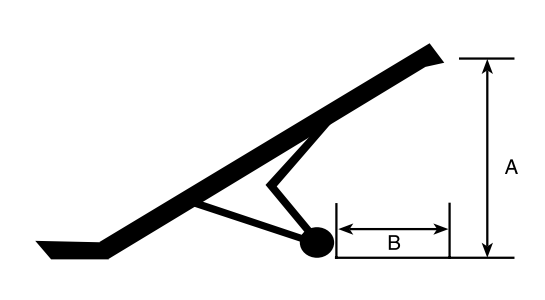

Ground Length

Do you want to keep your conveyor running at its optimum speed and at its optimum incline? Use the Westfield Ground Length calculator to measure the approximate distance your conveyor should be relative to the base of your bin.

- Determine the length (A) of your conveyor.

- Determine the height (B) your conveyor will be used at.

- Plug the values into the formula to figure the approximate ground length distance.

Formula: Pythagorean Theorem

A² + B² = C²

| Weight | 3850 lbs |

|---|