Baumalight 3P38 Stump Grinder | 60-110 HP | CAT 1/2 QH-Comp | 540 RPM | 9″ Max Cut Depth Per Pass

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB BV-ATWOOD, KS

*1 Or 2 Hyd Remotes Required – The WLS1050 Can Be Added If Tractor Only Has One Set Of Remotes. Also, Recommended For Improved Feathering Control On Smaller Tractors, Valve Is Close Center.

3 Point Hitch Stump Grinder – 3P38

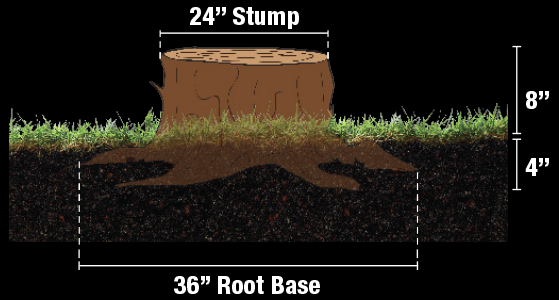

The 3P38 PTO stump grinder is designed for tractors equipped with a 540 RPM PTO and a high horsepower range of 60–110 HP, allowing you to grind stumps with tractor sizes that were not offered before. The stump grinder features a 34″ rotor carrying 52 replaceable carbide teeth that extend a full 1-¼ inches from the rotor, preventing chips and mulch from getting plugged. The rugged gearbox handles up to 110 HP and delivers 1,475 ft/lbs of stump-destroying torque. A 30″ wide and 12″ deep stump can be ground in 3 minutes with a 110 HP tractor, 4 minutes with a 100 HP tractor, and 6 minutes with a 70 HP tractor.

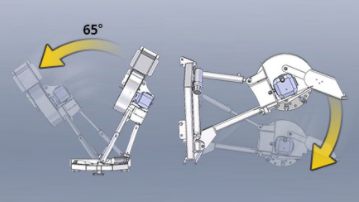

The rugged rotor also provides the stump grinder with extra momentum when grinding is tough, ensuring it can power through even the hardest stumps. With direct drive from the engine through the heavy-duty gearbox to the teeth, a PTO-driven stump grinder is the most efficient way to remove stumps for lawn care or fence row clearing. Spring bushings made of high-grade chrome-vanadium AISI 6150 spring steel are used on all main pivot points. The swing cylinder provides the operator with a 65-degree grinding range without moving the tractor. The heavy-duty base ensures stability during grinding, leading to more consistent performance and reduced stress on your tractor.

| Model No. | 1P14 | 1P24 | 3P24 | 3P34 | 3P38 | 3P40 |

|---|---|---|---|---|---|---|

| Recommended HP Size | 20-45 | 20-45 | 25-55 | 45-80 | 60-110 | 60-120 |

| Maximum Engine HP | 45 | 50 | 58 | 85 | 110 | 125 |

| Maximum PTO HP | 35 | 40 | 50 | 75 | 100 | 115 |

| Transmission | Hydrostatic only | Hydrostatic only | Any | Any | Any | Any |

| Hydraulic GPM | — | — | 5–20 | 5–20 | 5–20 | 5–20 |

| Rotor Size | 16″ | 24″ | 24″ | 34″ | 34″ | 34″ |

| Number of Teeth | 12 | 34 | 34 | 52 | 52 | 52 |

| Tooth Part number | H3000 | S1000 | S1000 | S1000 | S1000 | S1000 |

| Tooth Construction | High speed round tooth | Carbide steel bolt-in | Carbide steel bolt-in | Carbide steel bolt-in | Carbide steel bolt-in | Carbide steel bolt-in |

| Cutting Wheel Speed | 540 RPM | 540 RPM | 810 RPM | 810 RPM | 810 RPM | 1000 RPM |

| Cutting Height – Above Ground | 10″ | 10″ | 18″ | 25″ | 25″ | 25″ |

| Cutting Depth – Below Ground | 5″ | 6″ | 8″ | 14″ | 14″ | 14″ |

| Maximum Cutting Depth – Per Pass | 2″ | 5″ | 6″ | 9″ | 9″ | 9″ |

| Maximum Horizontal Cut | 18″ | 22″ | 22″ | 32″ | 32″ | 32″ |

| Swing Arc | 0° | 0° | 65° | 65° | 65° | 65° |

| Hub Torque | 664 Ft.-Lbs. | 885 Ft.-Lbs. | 885 Ft.-Lbs. | 1475 Ft.-Lbs. | 1475 Ft.-Lbs. | 1327 Ft.-Lbs. |

| Over Torque Protection | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch |

| Hitch | Cat I | Cat I | Cat I or II | Cat II | Cat II | Cat II |

| Quick hitch compatibility | Yes | Yes | No | No | No | No |

| No. of Remotes Required – Hydraulic | 0 | 0 | 1 or 2 | 1 or 2 | 1 or 2 | 1 or 2 |

| Requires 12 Volt DC | No | No | No | No | No | No |

| Input Speed | 540 | 540 | 540 | 540 | 540 | 1000 |

| Unit Weight (Shipping) Lbs. | 360 | 450 | 920 | 1231 | 1113.80 | 1280 |

| Width (Shipping) | 36″ | 36″ | 42″ | 48″ | 48″ | 48″ |

| Length (Shipping) | 30″ | 30″ | 49″ | 54″ | 54″ | 54″ |

FLOW CONTROL

Fine tune the performance of your Stump Blaster easily with the Flow Control knob. The Flow Control allows you to adjust the cutting pass speed, to match the size and performance of your tractor. This gives you the smoothest cut possible and with the full return back to the start position, the quickest overall stump grinding time possible.

CARBIDE TIPPED

Like the finest saw blades, the cutting teeth on Stump Blasters are carbide tipped. This incredibly hard material ensures reliable cutting performance. When grinding stumps, buried hazards are inevitable; gravel, stones even metal posts are not uncommon to “find”. Our carbide teeth are designed to stand up to this abuse and keep on blasting stumps to dust.

MORE TEETH

Many hands make light work, or in this case fine mulch faster and easier. The high number of teeth means that each tooth does less work. Each of the Stump Blasters teeth only need to make a small cut, because the work is shared by more of these rugged teeth, which last longer and typically only need 2 or 3 replaced at a time. The bolt-on designed teeth allow for straightforward replacement.

ROTOR

The massive ¾” thick steel rotor provides the back bone for the Stump Blaster cutting system. It’s the anchor for the carbide tipped teeth. For smooth operation it’s important that the rotor remains solid, with no flexing. The rugged rotor also provides the Stump Blaster with the extra momentum needed when the grinding is tough, making sure the Stump Blaster can power through the hardest stumps.

SWING & LIFT CYLINDERS

Get right to grinding with less maneuvering of your tractor and less damage to the grass. The swing cylinder gives the operator a 65 degree grinding range without moving the tractor. The lift cylinder allows you to raise and lower the grinding head to get in start position as well as lowering the head after a pass so you’re ready for the next bite.

| 1P14 | 12″ x 12″ cut

1P14 only must be mounted on a hydrostatic drive tractor |

| 1P24 | 12″ x 12″ cut

1P24 only must be mounted on a hydrostatic drive tractor |

| 1P24 | 12″ x 12″ cut

1P24 only must be mounted on a hydrostatic drive tractor |

| 3P24 | 12″ x 12″ cut

|

| 3P34 | 12″ x 12″ cut

|

| 3P38 |

|

| 3P40 | 12″ x 12″ cut

|

| Weight | 1114 lbs |

|---|

WLS1000

WLS1000