-

×

WL5089A100

1 × $620.00

WL5089A100

1 × $620.00 -

×

WLD004261

1 × $92.79

WLD004261

1 × $92.79

FGS952 Feller Buncher | Univ Skid | 52″ Dia Blade | 20″ Max Cut | T590 Motor 30-45 GPM

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB BV ATWOOD, KS

*Requires Case Drain (See Tab Below For Info On Case Drains)

*Hydraulic Hoses Included – NO Couplers (See Tab Below To Add Hyd Couplers)

*The FGS952 Comes With Baumalight’s Auxiliary Electrical Connection. Required Live Pins – 4 Hot On AUX (Wire With Pin Supplied To AUX On Boom) | When Ordering Unit, Please Note What Model Of Skid Steer It Is Going On & The Pin Connection. Baumalight Will Equip The Unit With Your Skid Steer’s Specific Auxiliary Connection Prior To Shipment.

- A Control Box Kit Must Be Added If –

- Your Skid Steer Is Older And Does Not Have An Auxiliary Electrical Connection

*Do You Have A Newer Bobcat Skid Steer With A Specific Bobcat 7-Pin Connector?

- To Run This Unit With Your Skid Steer, You Will Either Have To Add The Control Box Kit, Add The Bobcat 7-Pin CANBUS Plug/Circuit Board Kit, Or Contact Your Bobcat Dealer For A 7-Pin To 14-Pin Adapter.

*Some Skid Steers Have Issues With Clearance While Using This Attachment With The Lower Crossbar. Check Out Our Skid Steer Extension Plate For Newer Bobcat Skidsteers Or Any Others With A Low Cross Bar.

Feller Buncher For Skid Steer – FGS952

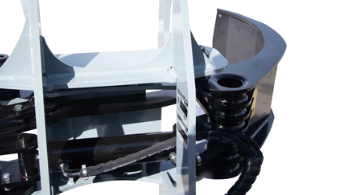

The FGS952 Skidsteer Mounted Feller Buncher we designed features a 52” cutting disc that can take up to 20” trees. The blade is specially designed using high alloy steel allowing it to be thinner which results in less binding and is equipped with 18 Beaver cutting teeth. The frame design allows more visibility for the operator and high stress areas use AR400 steel for added strength.

The grabber arms are equipped with a special valve that directs all hydraulic flow to the grabber cylinder for a much faster and more powerful hug on the tree.

It has an electric-over-hydraulic system which operates efficiently on hydraulic flows as little as 25 gpm and is powered by a bent axis piston motor. Only one set of remote hydraulics is required to operate all functions if you have an AUX electrical connection.

| Model No | FBS752 | FGS952 | FBXD752 |

| Baumalight Connection Code | – | – | A03 |

| Mounting type | Skidsteer Mounted | Skidsteer Mounted | Excavator Mounted |

| Blade position | Fixed Horizontal Blade | Fixed Horizontal Blade | 360° Slew drive |

| Adaptor | Universal Skidsteer Adaptor | Universal Skidsteer Adaptor | Bolt-on Adaptor Slew Drive |

| PSI | 4000 PSI | 4000 PSI | 4000 PSI |

| Case drain | Requires Case Drain – Critical | Requires Case Drain – Critical | Requires Case Drain – Critical |

| Electrical Requirement | Requires 12V Electric | Requires 12V Electric | Requires 12V Electric |

| Electric AUX | Four 12V positive switchable signals required | Two 12V positive switchable signals required | Six 12V positive switchable signals required |

| Wire Supplied or not | Wire Supplied to AUX | Wire Supplied to AUX | Wire NOT Supplied |

| Hydraulic Hose and Couplers | Hoses Included Couplers NOT Included |

Hoses Included & Couplers NOT Included | Hoses & Couplers NOT Included |

| Blade diameter | 52″ Diameter Blade | 52″ Diameter Blade | 52″ Diameter Blade |

| Maximum cut | 20″ Max Cut | 20″ Max Cut | 20″ Max Cut |

| Blade Material | 3/4″ Steel Blade | 5/8″ AR400 | 3/4″ Steel Blade |

| Cutt thickness | 1 5/8″ Cutt Thickness | 1 5/8″ Cutt Thickness | 1 5/8″ Cutt Thickness |

| Number of edges per Tooth | 4 Edges Per Tooth | 4 Edges Per Tooth | 4 Edges Per Tooth |

| Number of teeth | 18 Teeth | 18 Teeth | 18 Teeth |

| Tooth part number | B8000 Beaver Teeth | B8000 Beaver Teeth | B8000 Beaver Teeth |

| Throat Opening at teeth | Throat Opening at teeth: 36″ | 36″ Throat Opening | 36″ Throat Opening |

| Weight | 2850 lbs | 2250 lbs | 4415 lbs |

| MOTOR | MOTOR TYPE |

CC | CASE DRAIN |

IDEAL RPM |

20 GPM |

25 GPM |

30 GPM |

35 GPM |

40 GPM |

45 GPM |

|---|---|---|---|---|---|---|---|---|---|---|

| T590 | Bent Axis Piston | 108 | Critical | 800-1400 | — | 700 RPM | 900 RPM | 1050 RPM | 1230 RPM | 1400 RPM |

What Is A Case Drain Line ?

On most skidsteer and excavator Hydraulic systems, Hydraulic motors and pumps require a case drain line. Sometimes referred to as a third line, the case drain line will relieve any excess pressure and drain it back to your return line, then into the reservoir. Without a properly installed case drain, that extra pressure could blow a seal or damage your hydraulic line. For higher flow motors or on piston and gear motors, a case drain line is always required. Although, no matter the size of your motor, a case drain is always a good idea as it will relieve the amount of pressure on your shaft seal, helping to prolong its life. A case drain line can also increase the efficiency of your hydraulic system as it will lower the back pressure on the tank line.

Since most machines have a unique style of coupler, BaumaLight does not include a coupler on our case drain line, although they are available. If your skidsteer is not equipped with a case drain, then it can be field installed.

How Important Is A Case Drain Line ?

If we say having a case drain is critical and you operate without one, you will blow out your shaft seal. Be sure to check the motor sizing charts on our website.

Exception If You Have A Hammer Valve

There is one exception in the need for a case drain on gear motors and that is if you excavator is equipped with a hammer valve, this is a larger free flow line back to tank.

Identifying Your Case Drain Line

The following galleries show a highlighted case drain line on multiple skidsteer and excavator models.

Controls Overview

Auxiliary Connection (Included Standard)

*If you have a newer skid steer with auxiliary connection, please note what model of skid steer it is going on & the pin connection. Baumalight will equip the unit with your skid steer’s specific auxiliary connection prior to shipment. This Is The Ideal Solution. The operator can easily control all functions using the controls already equipped on the carrier joysticks. This allows the operator to never remove their hands from the controls to change a function.

Wired Control Box (Optional)

*If your skid steer is older & does not have an auxiliary electrical connection, you must add the WLD004956 wired control box. Although less than ideal, for controlling the attachment is using our wired control box. The operator would use the toggle switches on the control box to control the functions required. The wired control box requires a 12V connection to supply power.

Do You Have A Newer Bobcat Skid Steer With A Specific Bobcat 7-Pin Connector?

-If so, you will either have to add the control box kit, the Bobcat 7-pin CANBUS plug/circuit board kit, or contact your Bobcat dealer for a 7-pin to 14-pin adapter.

Bobcat 7-Pin CANBUS Plug/Circuit Board | 2 Direct Valves/4 Selector | 20% Off Shipped With Wholegood

$526.14

Baumalight Skid Steer Extension Plate For Newer Bobcat Skidsteers Or Any Others With A Low Cross Bar

$1,125.00

| Weight | 2250 lbs |

|---|