Baumalight S18 Stump Grinder | 25-80 HP | 12-27 GPM | 1.5-4T Ex | 24″ Rotor | 10″ Cut Depth | S550 Mtr | Less Mount

Hydraulic Couplers NOT Included

Case Drain Required

Self Regulated In-Feed

Must Add Mount To Complete – See Below

*PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

Skid Steer Specs

| Model No. | S14 | S18 | S24 | S28 | S40 |

|---|---|---|---|---|---|

| Recommended HP Size | 12-30 | 25-80 | 30-80 | 50-120 | 50-120 |

| Maximum Carrier Size | Check GPM & PSI | Check GPM & PSI | Check GPM & PSI | Check GPM & PSI | Check GPM & PSI |

| Motor Type | Gerotor | Gerotor | Gerotor | Gerotor | Bent Axis Piston |

| Hydraulic GPM | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart |

| Rotor Size | 18″ | 24″ | 24″ | 24″ | 24″ |

| Number of Teeth | 12 | 34 | 34 | 34 | 20 |

| Tooth Construction | Wearsharp® | Planer | Planer | Planer | Wearsharp® |

| Cutting Wheel Speed | Depends on GPM | Depends on GPM | Depends on GPM | Depends on GPM | Depends on GPM |

| Cutting Height – Above Ground | No limit | No limit | No limit | No limit | No limit |

| Cutting Depth – Below Ground | 6″ | 10″ | 10″ | 10″ | 24″ |

| Maximum Cutting Depth – Per Pass | 2″ | 5″ | 6″ | 6″ | 1″ |

| Maximum Horizontal Cut | 12″ | 22″ | 22″ | 22″ | 22″ |

| Swing Arc | Self-feeding | Self-feeding | 80° | 80° | 85° |

| Hub Torque | 150 Ft.-Lbs. | 250 Ft.-Lbs. | 250 Ft.-Lbs. | 803 Ft.-Lbs. | – |

| Over Torque Protection | Relieve valve | Relieve valve | Relieve valve | Relieve valve | Remote |

| Hitch | 1″ pivot pins | 1″ pivot pins | Quick Attach | Quick Attach | Quick Attach |

| No. of Remotes Required – Hydraulic | 1 | 1 | 1 | 1 | 1 |

| Requires 12 Volt DC | No | No | Yes | Yes | Yes |

| Unit Weight (Shipping) Lbs. | 394 | 642 | 995 | 995 | 1,200 |

Excavator Specs

| Model No. | S14 | S18 | GXM350 | GXM550 | GXM750 |

|---|---|---|---|---|---|

| Baumalight Connection Code | A04 | A04 | A02 | A02 | A02 |

| Recommended Carrier Size | 1-2 ton | 1.5-4 ton | 1.5-4.5 ton | 3.5-8 ton | 7-18 ton |

| Motor Type | Gerotor | Gerotor | High efficiency bent axis piston | High efficiency bent axis piston | High efficiency bent axis piston |

| Hydraulic GPM | Check Motor Options | Check Motor Options | Check Motor Options | Check Motor Options | Check Motor Options |

| Rotor Size | 18″ | 24″ | 19″ | 24″ | 24″ |

| Number of Teeth | 12 | 34 | 16 | 20 | 20 |

| Tooth Construction | Wearsharp® | Planer | Wearsharp® | Wearsharp® | Wearsharp® |

| Cutting Wheel Speed | Depends on GPM | Depends on GPM | Depends on GPM | Depends on GPM | Depends on GPM |

| Cutting Height – Above Ground | No limit | No limit | No limit | No limit | No limit |

| Cutting Depth – Below Ground | 6″ | 10″ | 16″ | 24″ | 24″ |

| Maximum Cutting Depth – Per Pass | 2″ | 5″ | 3/4″ | 1″ | 1″ |

| Maximum Horizontal Cut | 12″ | 22″ | 12″ | 22″ | 22″ |

| Over Torque Protection | Relieve valve | Relieve valve | Relieve valve | Relieve valve | Relieve valve |

| Hitch | 1″ pivot pins | 1″ pivot pins | Bolt on | Bolt on | Bolt on |

| No. of Remotes Required – Hydraulic | 1 | 1 | 1 | 1 | 1 |

| Requires 12 Volt DC | No | No | No | No | No |

| Unit Weight (Shipping) Lbs. | 394 | 642 | 650 | 822 | 1300 |

WEARSHARP® TEETH

By Green Manufacturing, Inc.

The unique design of the Wearsharp® allows the tooth to retain a sharp cutting surface, unlike traditional teeth that tend to round over. This provides a consistent cut throughout the life of the tooth, allowing you to maintain a faster sweep speed. This round tooth is 3 teeth in 1. Simply loosen the lock nut and rotate the tooth to a fresh, sharp cutting edge. This can be done three times, extending the life of each tooth.

MORE TEETH

The high number of teeth means that each tooth needs to do less work. Each of the Stump Blasters teeth only need to make a small cut, because the work is shared by more of our rugged teeth they last longer and usually only require 2 or 3 replacements at a time. The bolt-on designed teeth allow for straightforward replacement.

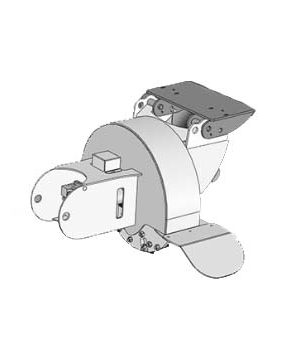

HYDRAULIC MOTOR

Skid steer mounted Stump Blasters run on hydraulic motors. For best results, match your equipments flow rate to one of our available hydraulic motor options.

MORE CLEARANCE

The Stump Blaster’s carbide teeth extend a full 1-¼ inches from the rotor. This prevents chips and mulch from getting plugged. More chip clearing produces smoother operation and reduces heat build-up that can damage the rotor and cause premature tooth failure.

ROTOR

The massive ¾” thick steel rotor provides the back bone for the Stump Blaster cutting system. It’s the anchor for the carbide tipped teeth. For smooth operation it’s important that the rotor remains solid, with no flexing. The rugged rotor also provides the Stump Blaster with the extra momentum needed when the grinding is tough, making sure the Stump Blaster can power through the hardest stumps.

GREASEABLE PINS

Our grease pins are zinc plated to prevent corrosion which will allow for smoother operation of the units joints over their lifetime.

What Is A Case Drain Line ?

On most skidsteer and excavator Hydraulic systems, Hydraulic motors and pumps require a case drain line. Sometimes referred to as a third line, the case drain line will relieve any excess pressure and drain it back to your return line, then into the reservoir. Without a properly installed case drain, that extra pressure could blow a seal or damage your hydraulic line. For higher flow motors or on piston and gear motors, a case drain line is always required. Although, no matter the size of your motor, a case drain is always a good idea as it will relieve the amount of pressure on your shaft seal, helping to prolong its life. A case drain line can also increase the efficiency of your hydraulic system as it will lower the back pressure on the tank line.

Since most machines have a unique style of coupler, BaumaLight does not include a coupler on our case drain line, although they are available. If your skidsteer is not equipped with a case drain, then it can be field installed.

How Important Is A Case Drain Line ?

If we say having a case drain is critical and you operate without one, you will blow out your shaft seal. Be sure to check the motor sizing charts on our website.

Exception If You Have A Hammer Valve

There is one exception in the need for a case drain on gear motors and that is if you excavator is equipped with a hammer valve, this is a larger free flow line back to tank.

Identifying Your Case Drain Line

The following galleries show a highlighted case drain line on multiple skidsteer and excavator models.

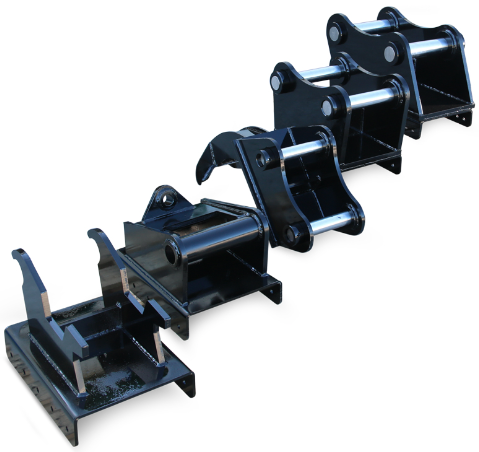

Excavator Mounting

Baumalight offers two options to mount your attachment on your excavator, blank weld-on plates & turn key custom solutions. All Baumalight excavator mounting options are manufactured in Canada and our team of experts will work with you to ensure you receive the best solution for your excavator.

Blank Weld-On Plates

The bank weld-on plate is designed for you to weld on your own ear lugs for your specific excavator mount. The bolt pattern in the plate lines up with the bolt pattern on Baumalight attachments, allowing you to bolt the attachment in place.

Turn-Key Custom Solutions

A fully customized solution, the team at Baumalight designs and builds your custom excavator adaptor for your specific excavator to ensure that the attachment is ready to go to work as soon as it arrives.

Add Connection Code

Click The Link Below To Find Your Specific D00**** Ex Mount

Add Turn Key Option That Corresponds With Your D00****

Please Note Your D00**** When Ordering

The Turn Key Pricing Includes The Connection Code Price

| Weight | 670 lbs |

|---|