S16 Electric Actuator Swing Stump Grinder | 12-20 GPM | 18″ Rotor | 6″ Cut Depth | S508 Mtr

Price Does Not Include Setup Or Shipping – F.O.B. Factory

*The Stump Grinder Is Not Equipped With Hydraulic Couplers. See Tab Below For Couplers & Info.

*The Unit Comes With Baumalight’s Auxiliary Electrical Connection. When Ordering Unit, Please Note What Model Of Mini Skid Steer It Is Going On & The Pin Connection. Baumalight Will Equip The Unit With Your Mini Skid Steer’s Specific Auxiliary Connection Prior To Shipment.

- A Control Box Kit Must Be Added If –

- Your Mini Skid Steer Is Older And Does Not Have An Auxiliary Electrical Connection

*Do You Have A Newer Bobcat Mini Skid Steer With A Specific Bobcat 7-Pin Connector?

- To Run This Unit With Your Mini Skid Steer, You Will Either Have To Add The Control Box Kit, Add The Bobcat 7-Pin CANBUS Plug/Circuit Board Kit, Or Contact Your Bobcat Dealer For A 7-Pin To 14-Pin Adapter.

*Other Color Options Available, But Must Be Special Ordered. Call For Details. Additional Charges Will Apply.

Mini Skidsteer Stump Grinder – S16

The S16 Skidsteer stump grinder features a specially designed electric actuator that controls the swing of the stump grinder. Equipped with high-performance electric linear actuators (12VDC) and limit switches, the actuator body is made of 304 stainless steel and has an IP69 rating. What sets this stump grinder apart is that it both has side to side swing and all the hydraulic oil from the mini skidsteer goes to the cutting head, the side-to-side swing is powered electronically, which greatly improves overall efficacy. The stump grinder’s rotor has double-side tooth setup that speeds up the grinding process, with each tooth only needing to make a small cut thanks to the high number of teeth. This means the teeth last longer and usually only require 2 or 3 replacements at a time. The stump grinder can cut up to 6 inches below ground with a swing radius of 58 degrees. The concave-shaped carbide tip of the high-speed teeth provides aggressive cutting action by chipping the brush bit by bit. The S16 model is ideal for mini skidsteer stump grinding on close-cut grass because the unit can sit stationary as the head swings from side to side.

The rotor’s unique positioning gives the operator an excellent view of the grinding action, and the heavy-duty fixed deflector safely directs the flow of debris. The S16’s size and dedicated mini skidsteer mount make it a great stump grinder for better access to tight areas, and it’s a nice addition to the rental offering on a mini skidsteer. The S16 comes with a C508 26 cc 10-18 GPM Bent Axis Piston Motor having a max PSI of 5000.

| Model No. | S14 | S16 | S18 | S24 | S28 | S40 |

|---|---|---|---|---|---|---|

| Recommended HP Size | Mini Skidsteer | Mini Skidsteer | 25-80 | 30-80 | 50-120 | 50-120 |

| Maximum Carrier Size | Check GPM & PSI | Check GPM & PSI | Check GPM & PSI | Check GPM & PSI | Check GPM & PSI | Check GPM & PSI |

| Motor Type | Gerotor | Bent Axis Piston | Gerotor | Gerotor | Gerotor | Bent Axis Piston |

| Hydraulic GPM | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart | Check Stump Cutting Size Chart |

| Rotor Size | 18″ | 18″ | 24″ | 24″ | 24″ | 24″ |

| Number of Teeth | 12 | 24 | 34 | 34 | 34 | 20 |

| Tooth Part number | H3000 | H3000 | S1000 | S1000 | S1000 | H3000 |

| Tooth Construction | High speed | High speed | Planer | Planer | Planer | High speed |

| Cutting Wheel Speed | Depends on GPM | Depends on GPM | Depends on GPM | Depends on GPM | Depends on GPM | Depends on GPM |

| Cutting Height – Above Ground | No limit | No limit | No limit | No limit | No limit | No limit |

| Cutting Depth – Below Ground | 6″ | 6″ | 10″ | 10″ | 10″ | 24″ |

| Maximum Cutting Depth – Per Pass | 2″ | 2″ | 5″ | 6″ | 6″ | 1″ |

| Maximum Horizontal Cut | 12″ | 12″ | 22″ | 22″ | 22″ | 22″ |

| Swing Arc | Self-feeding | 56° | Self-feeding | 60° | 63° | 85° |

| Hub Torque | 150 Ft.-Lbs. | – | 250 Ft.-Lbs. | 250 Ft.-Lbs. | 803 Ft.-Lbs. | – |

| Over Torque Protection | Relieve valve | Relieve valve | Relieve valve | Relieve valve | Relieve valve | Remote |

| Hitch | 1″ pivot pins | 1″ pivot pins | Mini Plate | Quick Attach | Quick Attach | Quick Attach |

| No. of Remotes Required – Hydraulic | 1 | 1 | 1 | 1 | 1 | 1 |

| Requires 12 Volt DC | No | Yes | No | Yes | Yes | Yes |

| Unit Weight (Shipping) Lbs. | 394 | 400 | 642 | 995 | 995 | 1,200 |

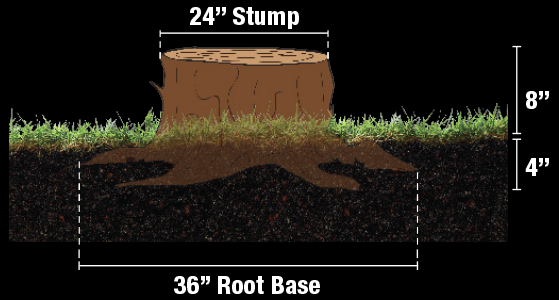

Stump Cutting Times Based On A 24″ Stump

| Motor | Case Drain | PSI | 12 GPM | 15 GPM | 20 GPM | 25 GPM | 30 GPM | 35 GPM | 40 GPM | 50 GPM | CC | Motor Type |

RPM at MAX GPM |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S508 Motor Available for : S16 |

Critcal | 2500 | 30 min | 30 min | 20 min | — | — | — | — | — | 25 | Piston | 2700 |

| 3,000 | 40 min | 25 min | 15 min | — | — | — | — | — | |||||

| S445 Motor Available for : S24 |

Recommended | 2500 | — | 60 min | 40 min | 35 min | — | — | — | — | 125 | Roller Vane | 520 |

| 3,000 | — | 50 min | 30 min | 30 min | — | — | — | — | |||||

| 3,500* | — | 50 min | 30 min | 30 min | — | — | — | — | |||||

| S545 Motor Available for : S24 |

Recommended | 2500 | — | 80 min | 40 min | 35 min | 25 min | 20 min | — | — | 130 | Roller Vane | 700 |

| 3,000 | — | 70 min | 30 min | 30 min | 20 min | 16 min | — | — | |||||

| 3,500* | — | 60 min | 30 min | 30 min | 20 min | 16 min | — | — | |||||

| S645 Motor Available for : S28 |

Recommended | 3,000 | — | 40 min | 40 min | 25 min | 15 min | 12 min | 10 min | — | 130 | Roller Vane | 540 |

| 3,500 | — | — | 30 min | 20 min | 12 min | 10 min | 8 min | — | |||||

| S740 Motor Available for : S40 |

Critcal | 2500 | — | — | 30 min | 15 min | 12 min | 10 min | — | — | 56 | Piston | 2100 |

| 3,000 | — | — | 25 min | 12 min | 10 min | 8 min | — | — | |||||

| 3,500 | — | — | 23 min | 10 min | 8 min | 6 min | — | — | |||||

| S770 Motor Available for : S40 |

Critcal | 2500 | — | — | — | 30 min | 12 min | 10 min | 8 min | 7 min | 84 | Piston | 2000 |

| 3,000 | — | — | — | 25 min | 10 min | 8 min | 7 min | 6 min | |||||

| 3,500 | — | — | — | 23 min | 8 min | 6 min | 5 min | 4 min |

* Motor will run at this PSI, but excess pressure is dumping over relief.

5 GPM is used for swing cylinder.

MORE TEETH

The high number of teeth means that each tooth needs to do less work. Each of the Stump Grinders teeth only need to make a small cut, because the work is shared by more of our rugged teeth they last longer and usually only require 2 or 3 replacements at a time. The bolt-on designed teeth allow for straightforward replacement.

ROTOR

The massive ½” thick steel rotor provides the back bone for the Stump Grinder cutting system. It’s the anchor for the carbide tipped teeth. For smooth operation it’s important that the rotor remains solid, with no flexing. The rugged rotor also provides the Stump Grinder with the extra momentum needed when the grinding is tough, making sure the Stump Grinder can power through the hardest stumps.

HIGH SPEED TEETH

The concave shaped carbide tip of our High Speed Teeth provide aggressive cutting action by chipping the brush bit by bit. This round tooth is 3 teeth in 1. Simply loosen the lock nut and rotate the tooth to a fresh, sharp cutting edge. This can be done three times, extending the life of each tooth.

*The Unit Comes With Baumalight’s Auxiliary Electrical Connection. When Ordering Unit, Please Note What Model Of Mini Skid Steer It Is Going On & The Pin Connection. Baumalight Will Equip The Unit With Your Mini Skid Steer’s Specific Auxiliary Connection Prior To Shipment.

- A Control Box Kit Must Be Added If –

- Your Mini Skid Steer Is Older And Does Not Have An Auxiliary Electrical Connection

*Do You Have A Newer Bobcat Mini Skid Steer With A Specific Bobcat 7-Pin Connector?

- To Run This Unit With Your Mini Skid Steer, You Will Either Have To Add The Control Box Kit, Add The Bobcat 7-Pin CANBUS Plug/Circuit Board Kit, Or Contact Your Bobcat Dealer For A 7-Pin To 14-Pin Adapter.

*The stump grinder is not equipped with hydraulic couplers. Install couplers and connect your skidsteer pressure, return, & case drain (if equipped) hoses to the stump grinder hoses. Install your couplers to the hoses listed in the table below. Identify the pressure port hose and connect your hoses to the cutter hoses

| Fitting Size | Hose Description | Qty |

| 3/4 JIC FM | Pressure & Return | 2 |

| 3/8 JIC FM | Case Drain | 1 |

| Weight | 400 lbs |

|---|