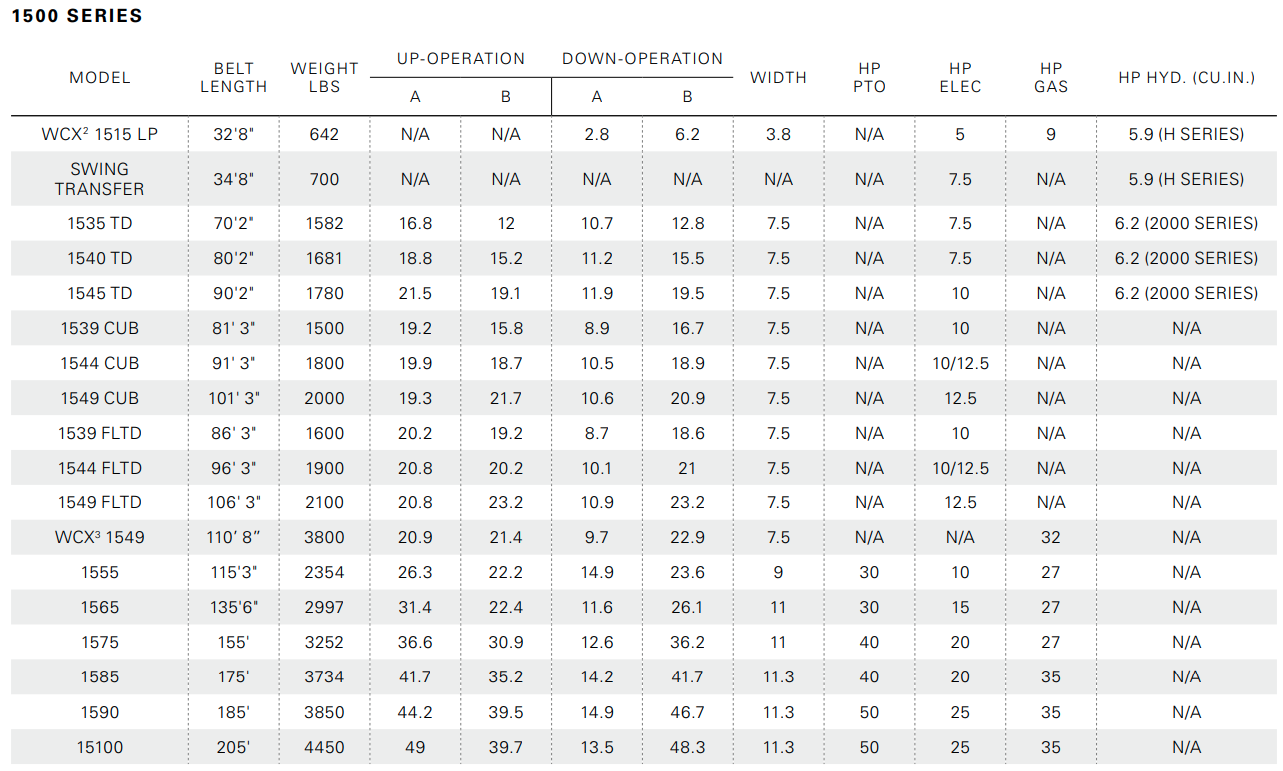

FX4 1539FLTD Conveyor | Pinch Top Drive | 15″ Belt | 39′ Length | Up To 6,800 BPH | Gas,Hyd,Or Elec

PRICE DOES NOT INCLUDE SETUP OR SHIPPING – PRICED FOB FACTORY

Must Add Drive To Complete Unit – See Requirements Below

- Belt Conveyor Advantages

- 1500 Series Field Loaders

- S Drive Vs. Top Drive

- Top Drive Benefits

- Specs

- Drive Kits

- Options

- Conveyor Calculators

Westfield Belt Conveyors

AGI Westfield Belt Conveyors are built tough to perform, yet designed and engineered for gentle handling of delicate seeds and commodities.

Gentle Handling

Specialty crops, seed and some commodities are very susceptible to impact damage caused by conventional grain handling systems. AGI Westfield Belt Conveyors minimize impact damage and help protect grade quality and germination performance of seed.

Low Maintenance / Long Wear

Engineered, designed and built for rugged, long-lasting performance with heavy-duty features like our quality rubber belting, rated up to 3,000 hours.

High Capacity

All AGI Westfield Conveyors are designed and built for high capacity and performance. Capacity increases as the angle of elevation decreases. See specifications for model performance.

Low HP

AGI Westfield’s unique design requires half the horsepower of screw augers, saving energy and freeing up larger tractors for other purposes.

Clean Convenience

AGI Westfield Belt Conveyors require very little clean-out when changing from one commodity to another; saving growers time and reducing contamination.

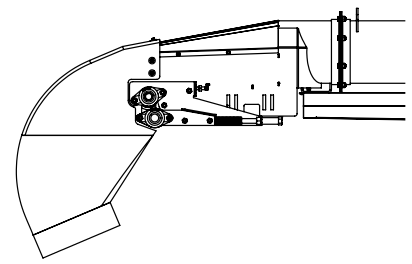

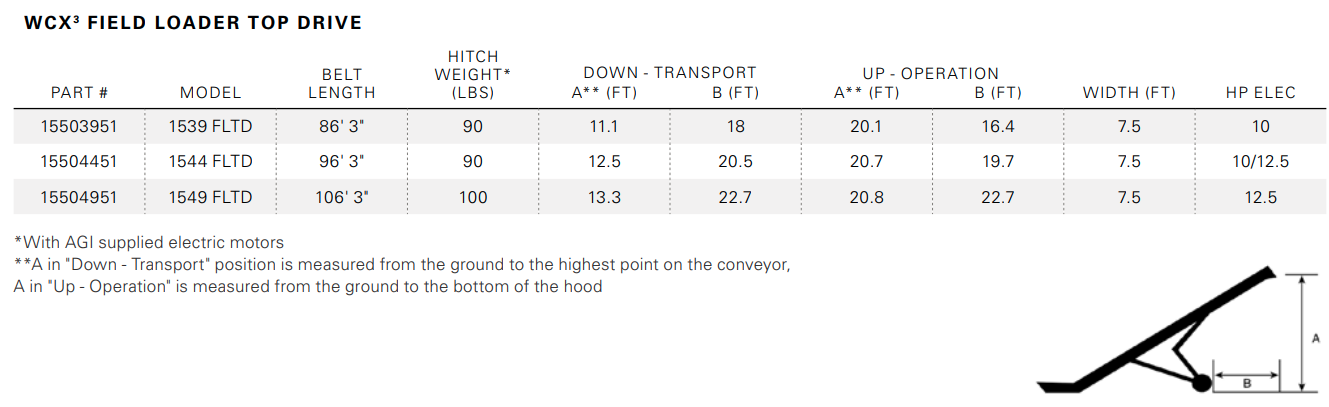

WCX3 1500 Series Field Loaders

10″ Tube | 15″ Belt | Capacity up to 10,000 BPH

The all new WCX3 has been designed to handle anything a farm throws at it. This latest model has been scrutinized from hopper to spout with our operators in mind. Find the unit right for your operation.

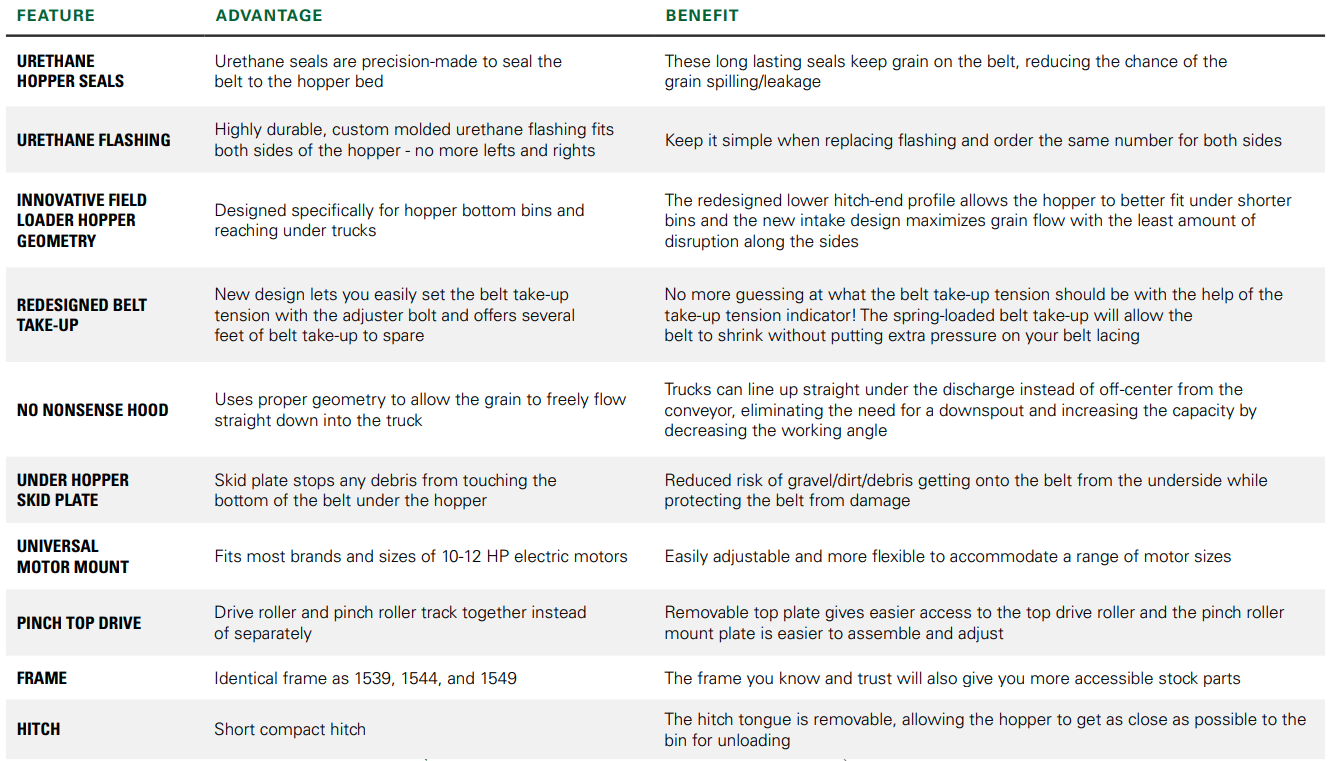

Features

• Redesigned S-Drive with longer take-up which can be adjusted with normal tools and no longer runs the risk of over-tightening

• Grain flows straight down from the spout with the newly redesigned No-Nonsense Hood

• Precision-made urethane hopper seals secure the belt to the hopper bed reducing the chance of spillage/leakage

• Under hopper skid plate stops debris from touching the bottom of the belt, keeping it off the belt and protecting the belt from damage

• Two optional gas engines to choose from: 33 EFI or 32 HP Carb

• Available with the motor above or below the tube

FMD (Full Meal Deal)

Available In 49′ length

• All grain commodity system suitable for all seed types, including oil seeds

• Easy to use Turbo Clean Wash System removes debris and residue from tough to wash commodities, like fertilizer or oil seeds

• Beat build-up and keep your belt cleaner for longer with the help of two new belt scrapers and a belt brush

• Parallel hopper cloth stays 32″ wide for the full working length

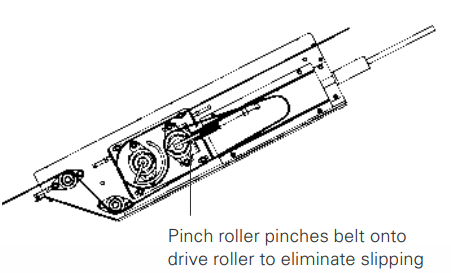

Pinch S Drive VS Pinch Top Drive

Pinch S Drive

AGI Westfield’s unique Pinch S-Drive is available on all S-Drive models and eliminates slippage by making it easy to set and maintain belt traction. The spring take up helps to maintain tension while less friction minimizes damage to the conveyor belt, also invoking minimal stress on the bearings. Gas, electric or PTO Pinch S-Drive options available.

Drive Kit & Switch Box (Must Add)

Motors (Select One)

Pulley (Must Add)

Hyd Drive Kit (Must Add)

*Setup With This Kit Requires 10 Gallons Of Hyd Oil*

Gas / Hyd Kit (Select)

Gas Motor (Select One)

Exhaust Kit – Must Add With Either Motor

Ignition Wiring Kit – Must Add With 40 HP Motor

Westfield Conveyor Calculator

Find a conveyor that best fits your grain handling needs. Use the Westfield Calculator to help you determine:

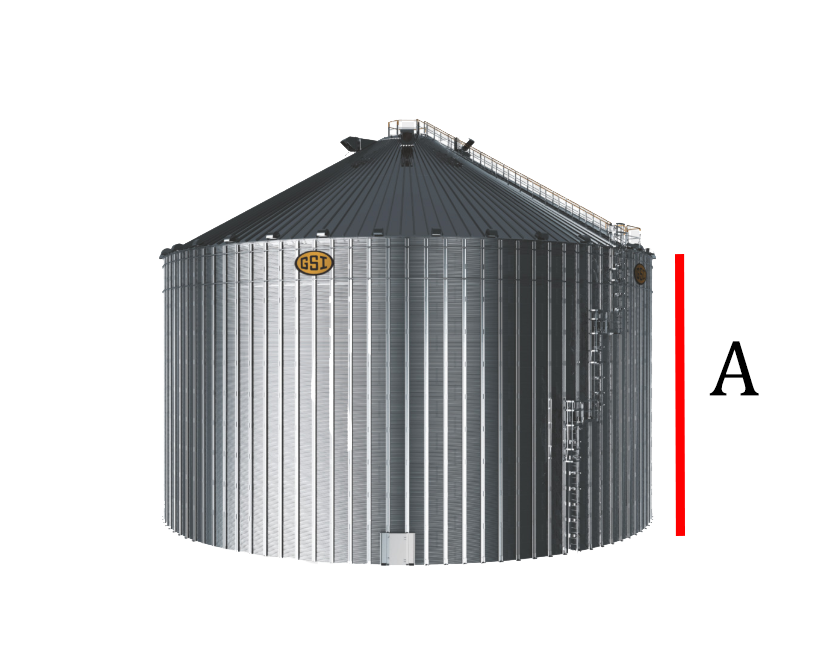

A. What length of conveyor will best complement you bin height

B. How much ground length is necessary to ensure your conveyor will reach the desired bin height

The Westfield Calculator is easy to use and is designed to be practical. Use the Westfield Calculator as a tool to help you with your next conveyor purchase!

A. Conveyor Length

Do I need a 91 foot conveyor, or will a 31 foot conveyor do? Find out what conveyor length is the right choice for you bin’s peak height by using the Westfield Conveyor Length Calculator.

- Determine distance (A) from ground to eave of bin.

- Multiply the distance (A) by 2.5 to figure the minimum conveyor length needed.

Example: Bin height of 30’ X 2.5= 75’ – 75’ would be minimum length of conveyor you would want to look at.

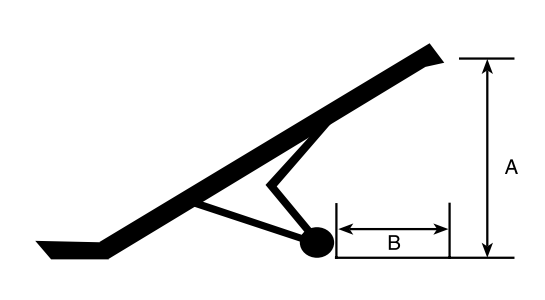

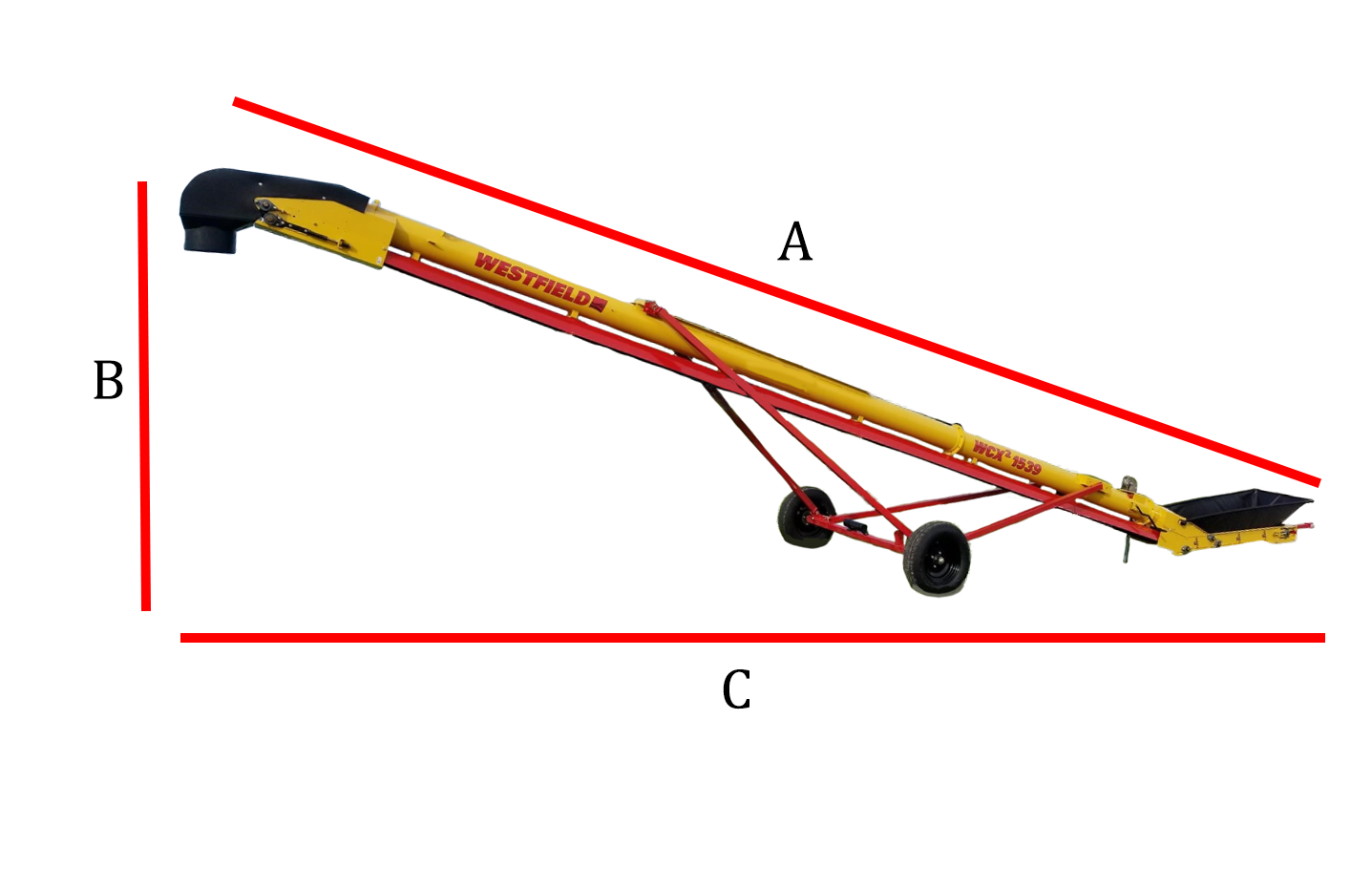

B. Ground Length

Do you want to keep your conveyor running at its optimum speed and at its optimum incline? Use the Westfield Ground Length calculator to measure the approximate distance your conveyor should be relative to the base of your bin.

- Determine the length (A) of your conveyor.

- Determine the height (B) your conveyor will be used at.

- Plug the values into the formula to figure the approximate ground length distance.

Formula: Pythagorean Theorem

A² + B² = C²

| Weight | 1730 lbs |

|---|